Organic-inorganic composite phase-change energy-storage gypsum building block

An inorganic composite, phase-change energy storage technology, applied in the field of building energy storage composite materials, can solve the problems of large volume change, low thermal conductivity, and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

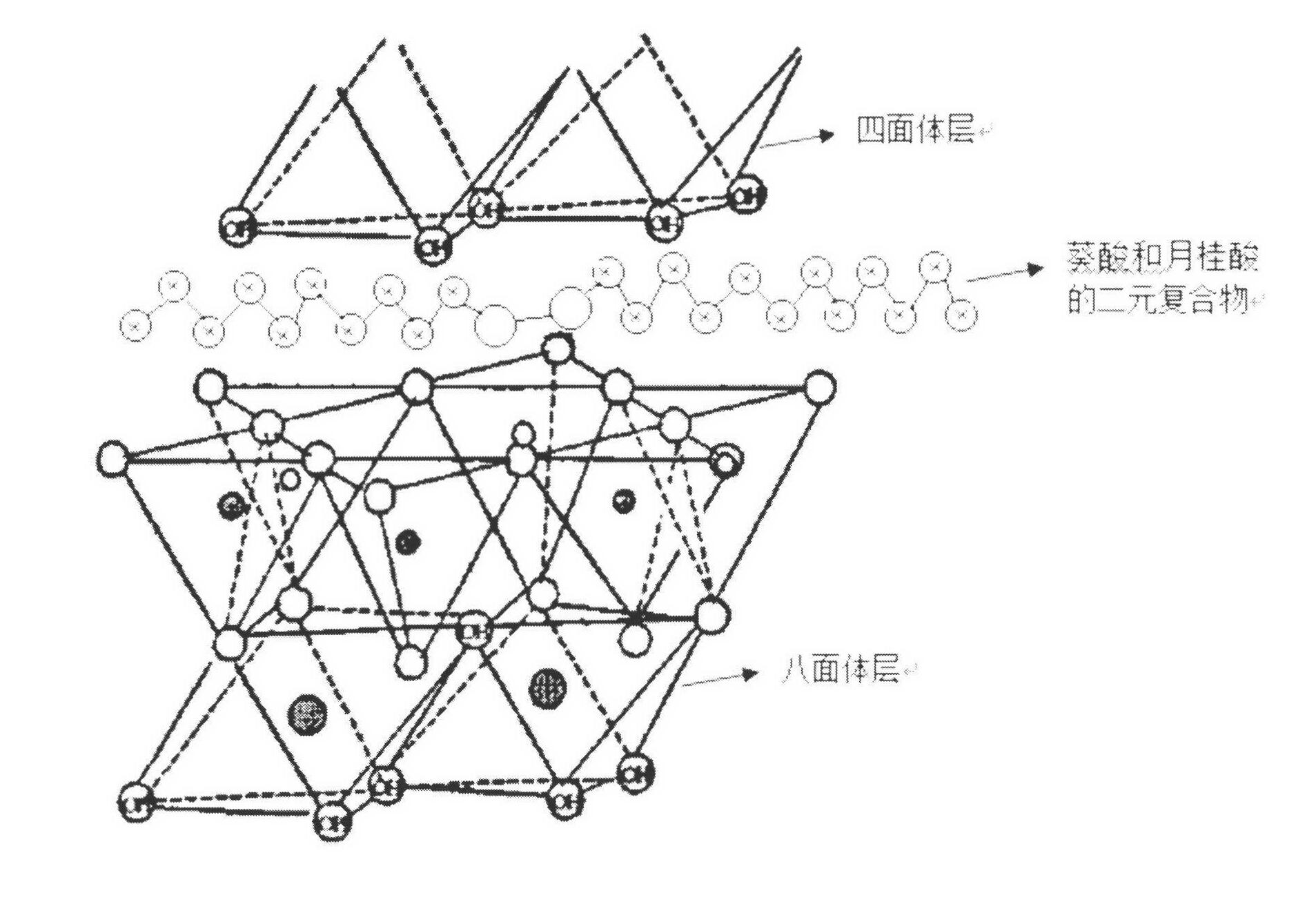

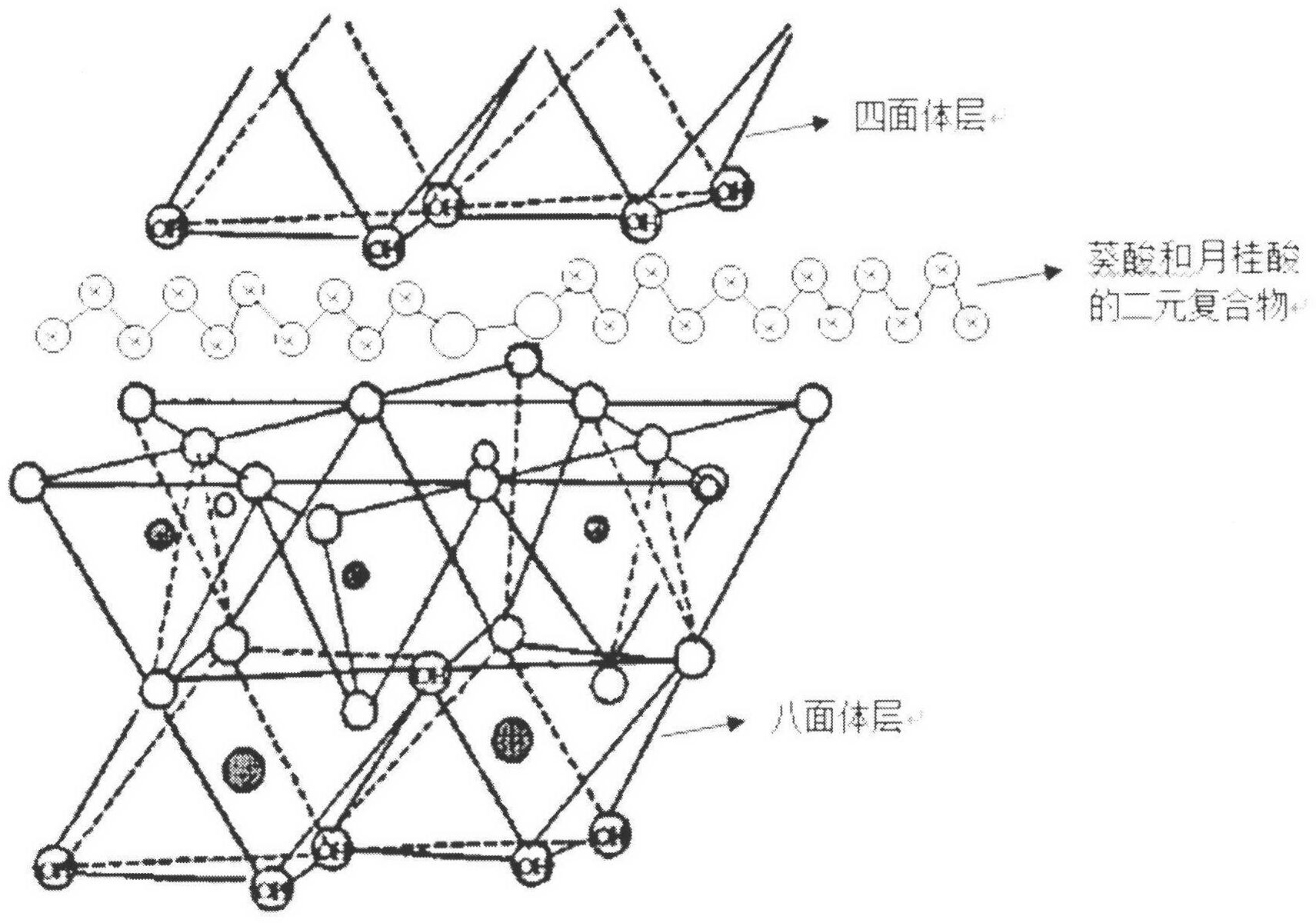

[0015] (1) Add coal-series kaolin (1250 mesh) that has been crushed, dried, ground and removed to 50% hydrazine hydrate solution, ultrasonically disperse for 1 hour, wash and dry to obtain hydrazine / coal-series kaolin intercalation material.

[0016] (2) Mix 80 parts of hydrazine / coal-based kaolin intercalation material with 5 parts of capric acid and 15 parts of lauric acid, stir at 80°C for 3 hours, and cool to room temperature to obtain an organic-inorganic composite phase change material.

[0017] (3) Mix 100 parts of desulfurized building gypsum, 5 parts of organic-inorganic composite phase-change materials, 0.2 parts of aluminum powder and 70 parts of water, stir for 2 minutes, then form it, and dry it in an oven at 40±2°C to obtain an organic-inorganic composite phase Variable energy storage gypsum block.

Embodiment example 2

[0019] (1) Add coal-series kaolin (1250 mesh) that has been crushed, dried, ground and removed to 50% hydrazine hydrate solution, ultrasonically disperse for 1 hour, wash and dry to obtain hydrazine / coal-series kaolin intercalation material.

[0020] (2) Mix 85 parts of hydrazine / coal-based kaolin intercalation material with 3 parts of capric acid and 12 parts of lauric acid, stir at 80°C for 3 hours, and cool to room temperature to obtain an organic-inorganic composite phase change material.

[0021] (3) Mix 100 parts of desulfurized building gypsum, 10 parts of organic-inorganic composite phase-change materials, 0.4 parts of aluminum powder and 70 parts of water, stir for 2 minutes, shape, and dry in an oven at 40±2°C to obtain an organic-inorganic composite phase Variable energy storage gypsum block.

Embodiment example 3

[0023] (1) Add coal-series kaolin (1250 mesh) that has been crushed, dried, ground and removed to 50% hydrazine hydrate solution, ultrasonically disperse for 1 hour, wash and dry to obtain hydrazine / coal-series kaolin intercalation material.

[0024] (2) Mix 88 parts of hydrazine / coal-based kaolin intercalation material with 3 parts of capric acid and 9 parts of lauric acid, stir at 80°C for 3 hours, and cool to room temperature to obtain an organic-inorganic composite phase change material.

[0025] (3) Mix 100 parts of desulfurized building gypsum, 15 parts of organic-inorganic composite phase change materials, 0.6 parts of aluminum powder and 70 parts of water, stir for 2 minutes, then form it, and dry it in an oven at 40±2°C to obtain an organic-inorganic composite phase Variable energy storage gypsum block.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com