Surface treatment method for zirconium oxide body, zirconium oxide veneering porcelain composite material and preparing method thereof

A treatment method and technology of zirconia bodies, which are applied in the field of zirconia ceramic composite materials and their production, and the surface treatment of zirconia bodies, can solve the problems of low bonding strength of decorative porcelain, cracking or falling off of decorative porcelain, and achieve treatment The method is simple and convenient, the bonding strength is improved, and the effect of increasing the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The surface treatment method of zirconia body provided by the invention is divided into two steps.

[0040] Step 1: Fusing a glass-ceramic layer on the surface to be treated of the zirconia body

[0041] First, the glass ceramic powder is mixed with a solvent to make a paste, and evenly coated on the surface of the zirconia body to be treated; then the zirconia body coated with the glass ceramic powder is dried, and then sintered to make the glass ceramic powder Fused on the surface of zirconia;

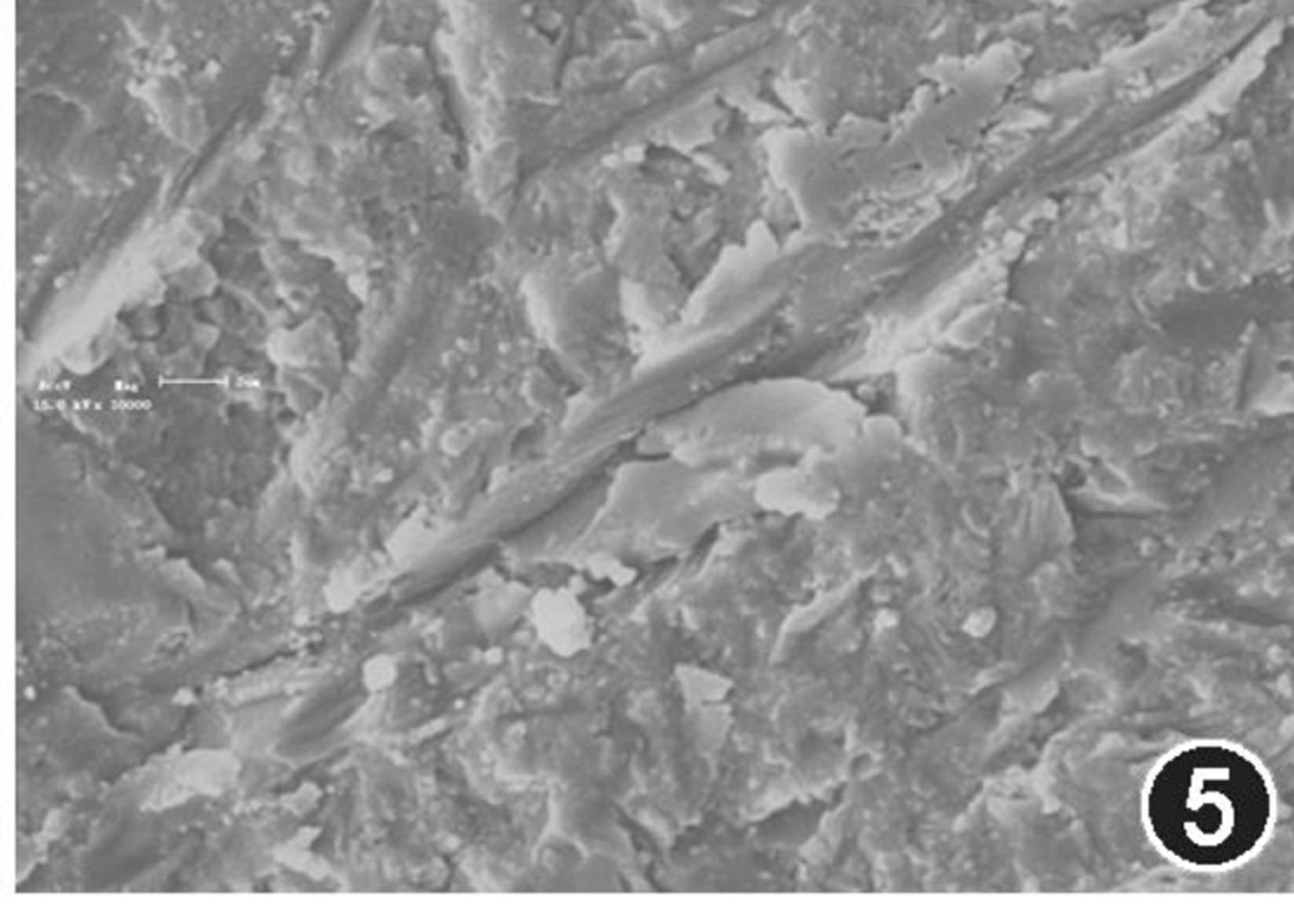

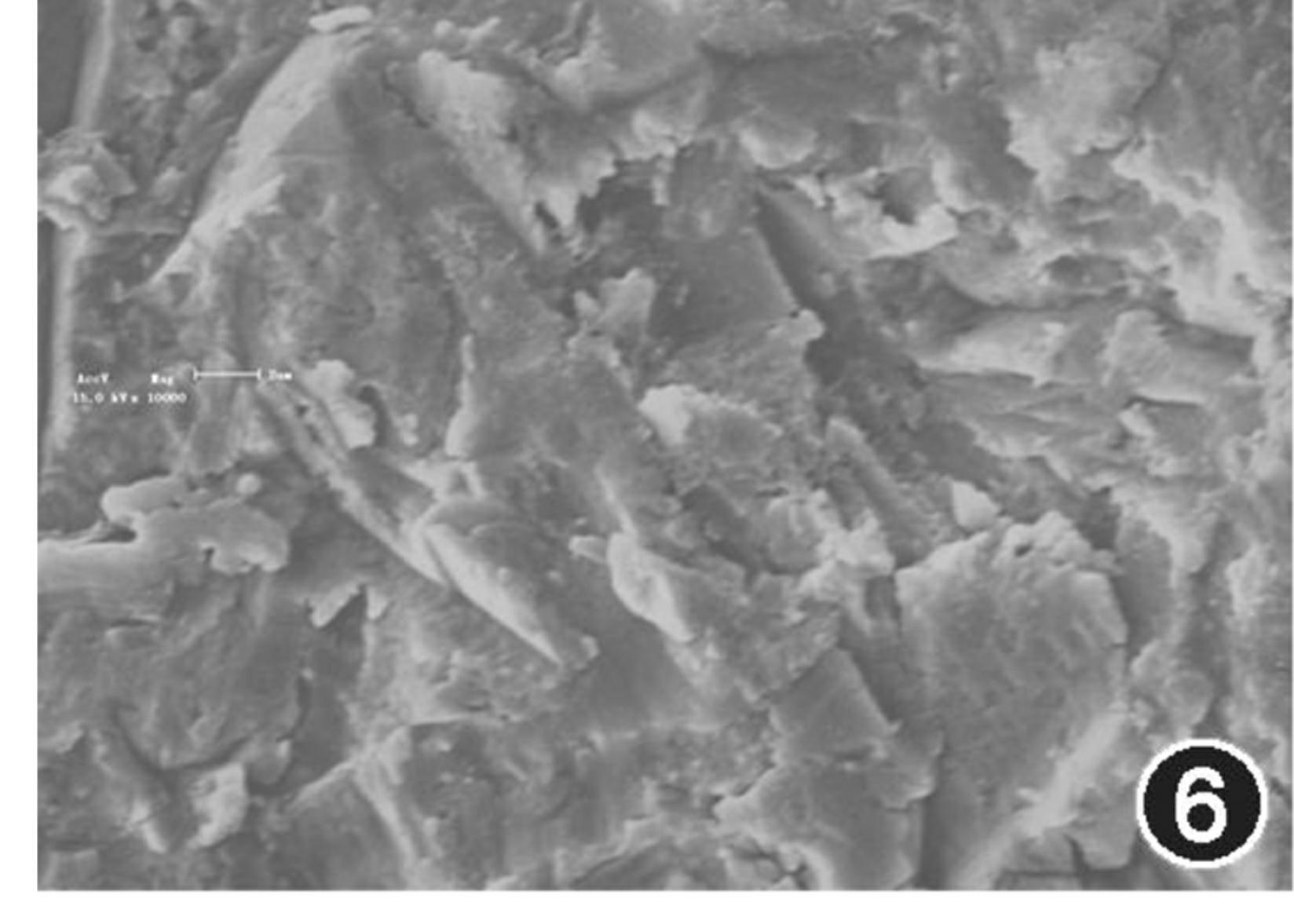

[0042] Step 2: Acid etching of the zirconia body

[0043] The zirconia body sintered with the glass-ceramic layer is put into the hydrofluoric acid solution, so that the glass-ceramic layer on its surface is completely acid-etched away, and the zirconia substrate is exposed.

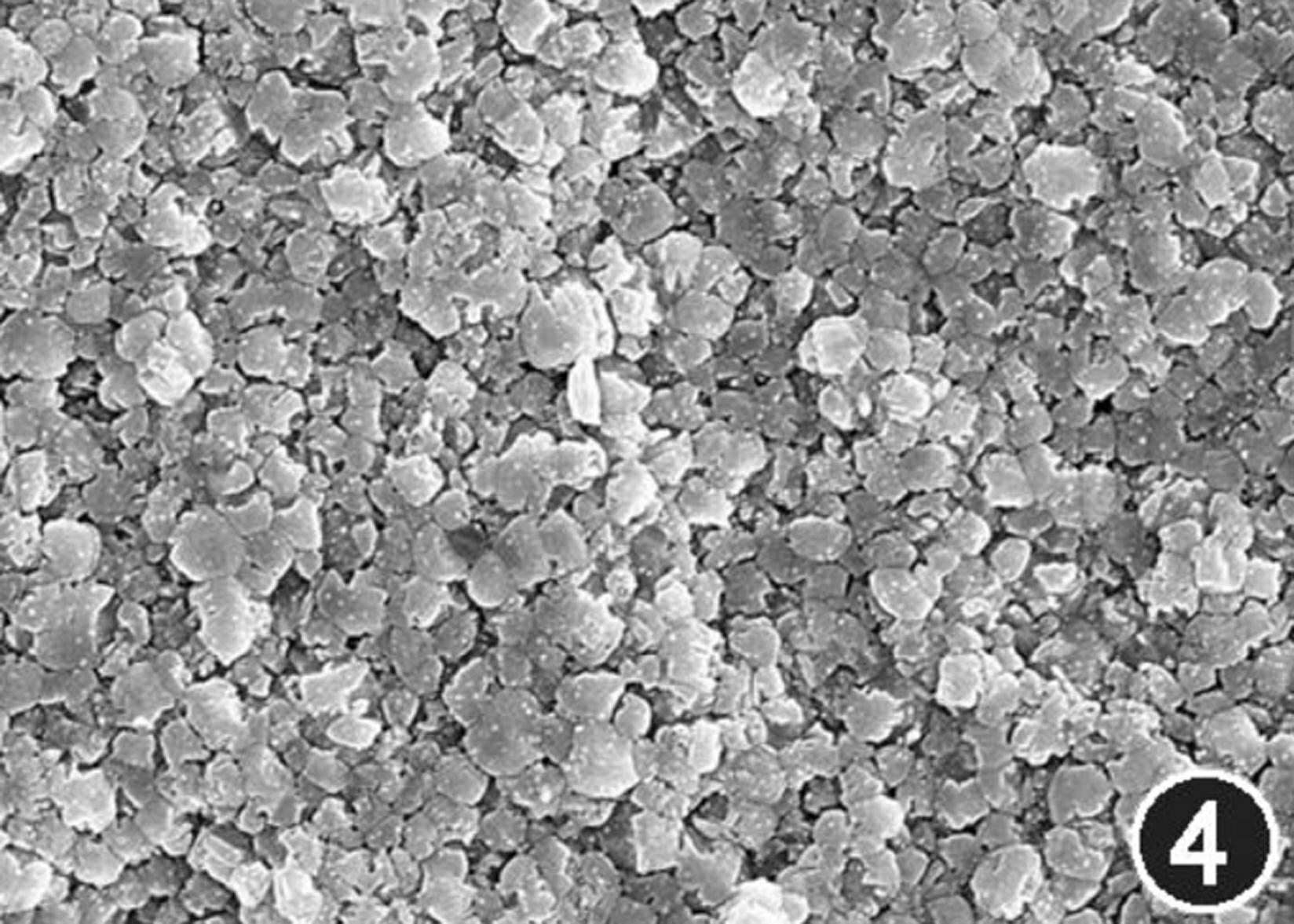

[0044] The specific method is: mix IPS.E Max zirliner porcelain powder and pure water at a ratio of 0.2g / 0.1ml to form a uniform paste, and evenly apply it on the surface of the zirconia body. In the G...

Embodiment 2

[0083] The treatment method in Example 1 is applied to the zirconia body, and the treated surface of the zirconia body after treatment is used for bonding decorative porcelain. The specific method is as follows:

[0084] Step 1: Mix Yimei IPS.E Max zirliner porcelain powder and purified water at a ratio of 0.2g / 0.1ml to form a uniform paste, evenly spread it on the surface of zirconia, and sinter it in a 40T porcelain furnace (Germany) according to the following procedures: Pre-drying for 6 minutes → initial temperature 403°C → 40°C / min → final temperature 960°C for 1 minute, → natural cooling to room temperature. The process from applying the porcelain powder is repeated again.

[0085] Step 2: Etching in 10% hydrofluoric acid aqueous solution (HF) for 15 minutes. Rinse with high-pressure air and water for 1 min and dry.

[0086] The thickness of the porcelain powder is about 1.5-3mg / mm on the surface of the zirconia body 2 , spread evenly.

[0087] Step 3: Sinter the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com