Construction method for upstream-side wall body of semi-underground power station plant

A side wall, underground type technology, applied in the directions of hydropower stations, buildings, hydropower generation, etc., can solve the problems of difficulty in meeting the operation requirements of the bridge cranes of the power station, large displacement of the upstream side wall, and increased construction costs, and achieve a good operating environment. , low cost, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

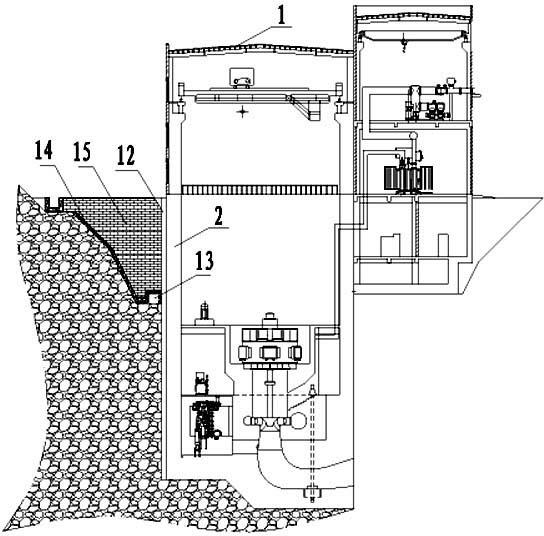

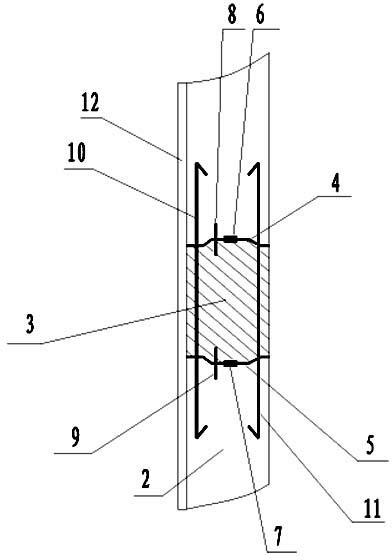

[0013] Such as figure 1 , 2 As shown, the construction method of the upstream side wall of the semi-underground power station building in the present invention includes building a power station building 1 with a concrete structure on the bank of the downstream river bank of the dam water diversion system, and the power station building 1 is embedded in the rock wall part underground. The longitudinal center line of the upstream side wall 2 is poured with post-cast compensating concrete, that is, the post-cast strip 3; the thickness of the post-cast strip 3 is consistent with that of the upstream side wall, and the width is 2 meters; the post-cast strip 3 and the corresponding upstream side wall Steel wire meshes 4 and 5 are respectively arranged on the contact surface of the body 2, and water-swellable water-stop strips 6 and 7 are respectively arranged along the longitudinal centerline of each piece of steel mesh 4 and 5; Copper water-stop sheets 8 and 9 are arranged respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com