Heat insulation composite plate of outer wall and preparation method thereof

An external wall insulation and composite board technology, which is applied in the fields of thermal insulation, chemical instruments and methods, building components, etc., can solve the problems of inability to overcome the defects of rock wool board, single use method of rock wool board, difficult quality assurance management, etc., and achieve economical savings. Labor cost and time, easy assembly, and improved operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

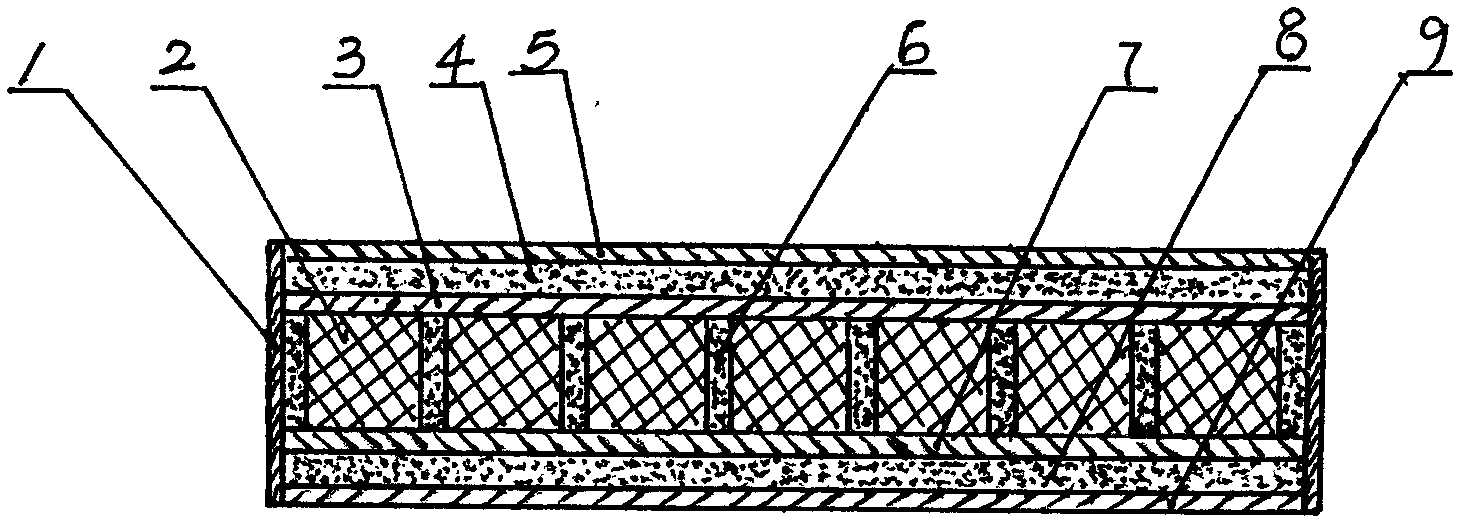

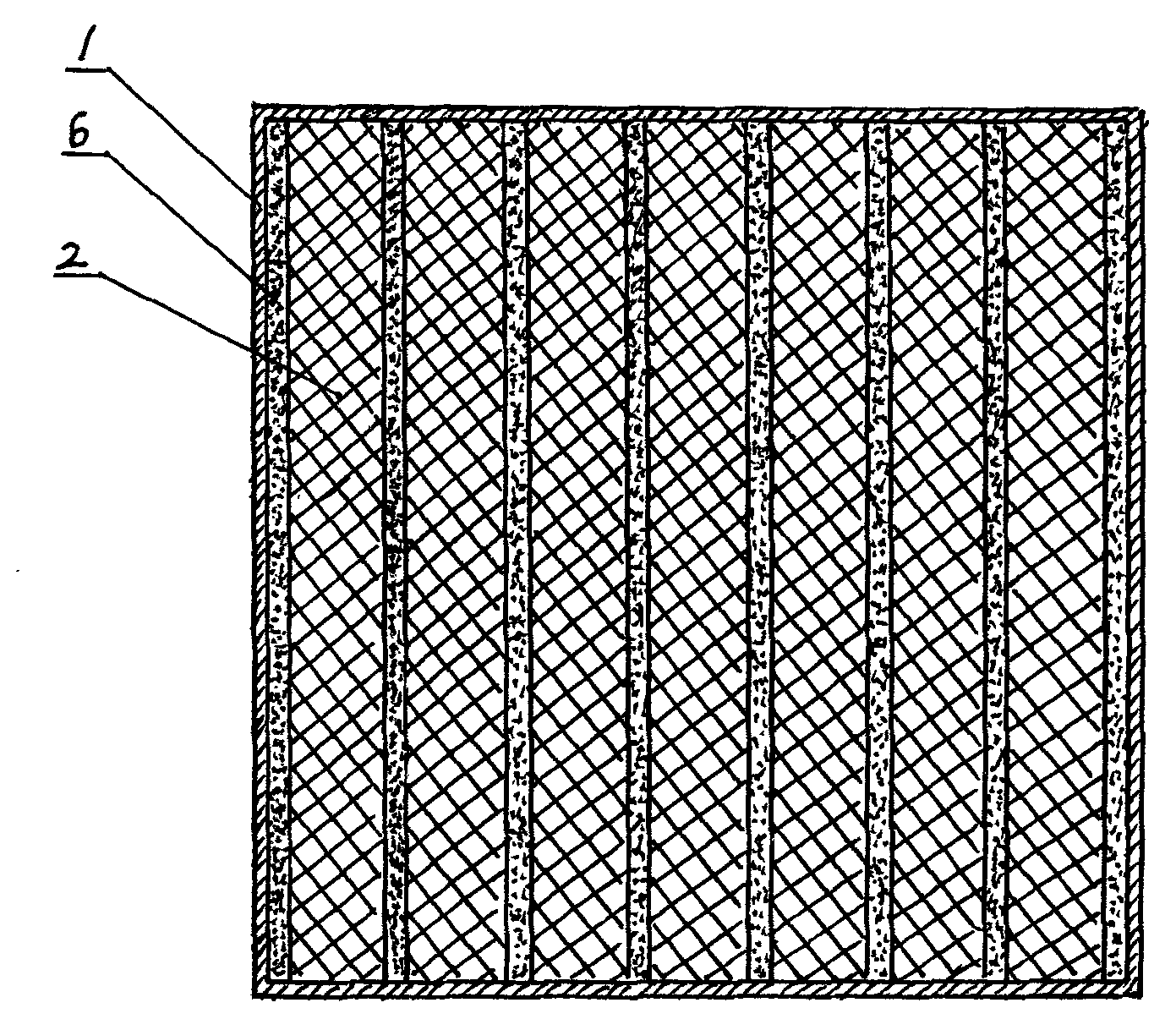

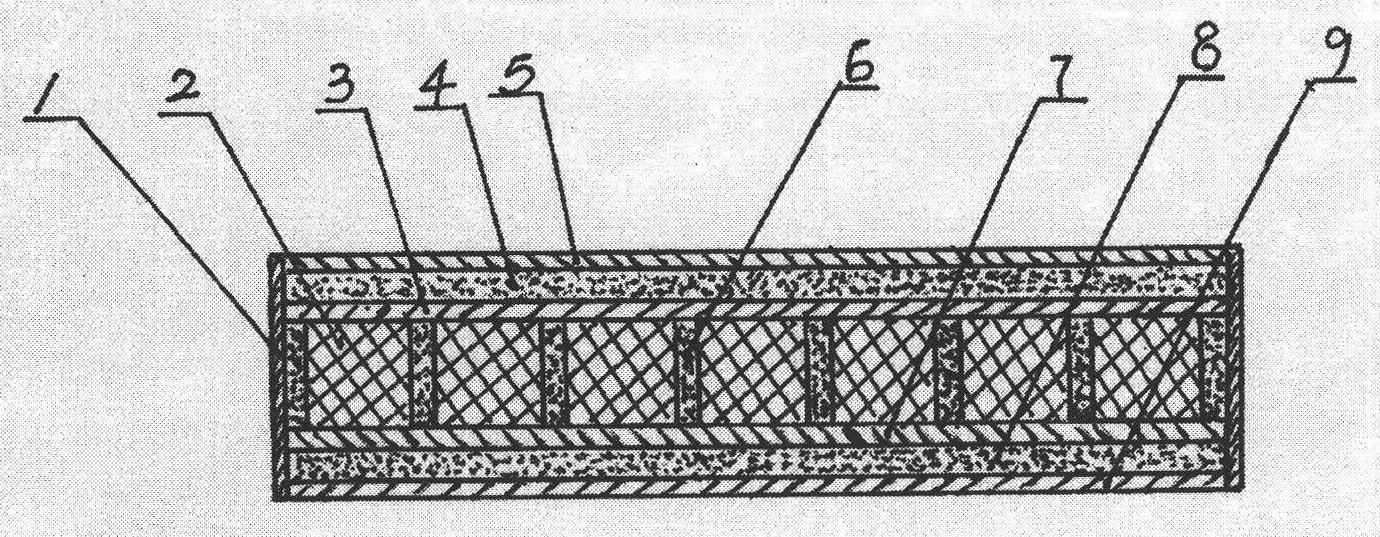

[0014] The external wall thermal insulation composite board of the present invention is a layered structure, which is composed of an upper panel 4, a lower panel 8 and a core material, wherein the upper and lower panels are made of various building external wall thermal insulation materials, and the building The thermal insulation material of the outer wall is powdery and can be diluted with water to form a mortar. The core material 2 can use various thermal insulation materials. The two sides of the upper and lower panels are respectively a layer of glass fiber mesh cloth 3, 9 and non-woven fabrics 5, 7 , the core material 2 between the upper and lower panels is a strip-shaped thermal insulation material, and there is a gap of 2-3mm between the strip-shaped thermal insulation materials. Edge banding 1 adopts glass fiber mesh cloth.

[0015] The manufacture method of the exterior wall thermal insulation composite board of the present invention is as follows:

[0016] (1) Lay ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com