Nitrogen spring type hydraulic chuck

A nitrogen gas spring and hydraulic chuck technology, which is used in drilling equipment, earthwork drilling, drill pipe, etc., can solve the problems of troublesome replacement, short life and high cost, and achieve convenient replacement and maintenance, long service life and stable performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

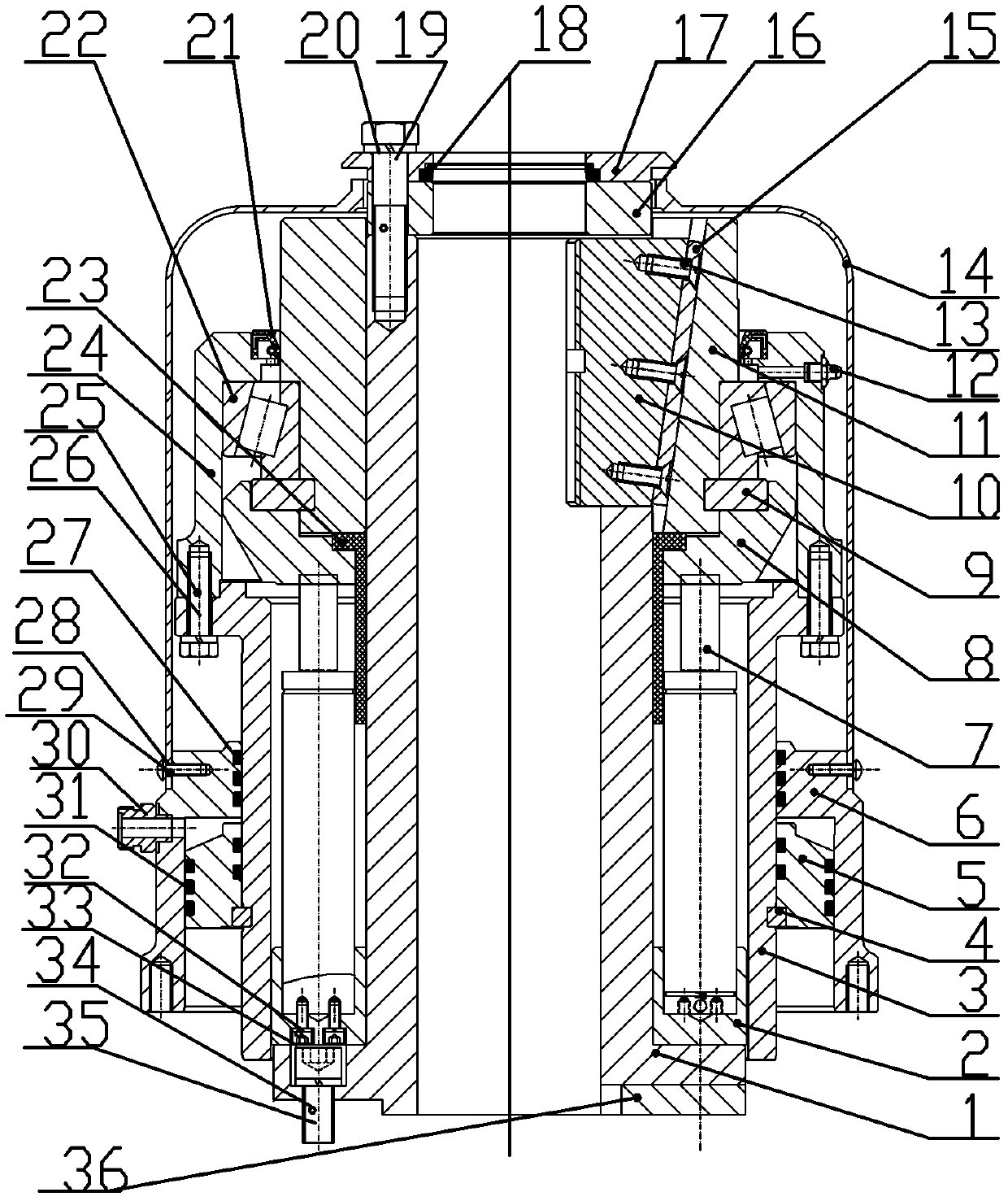

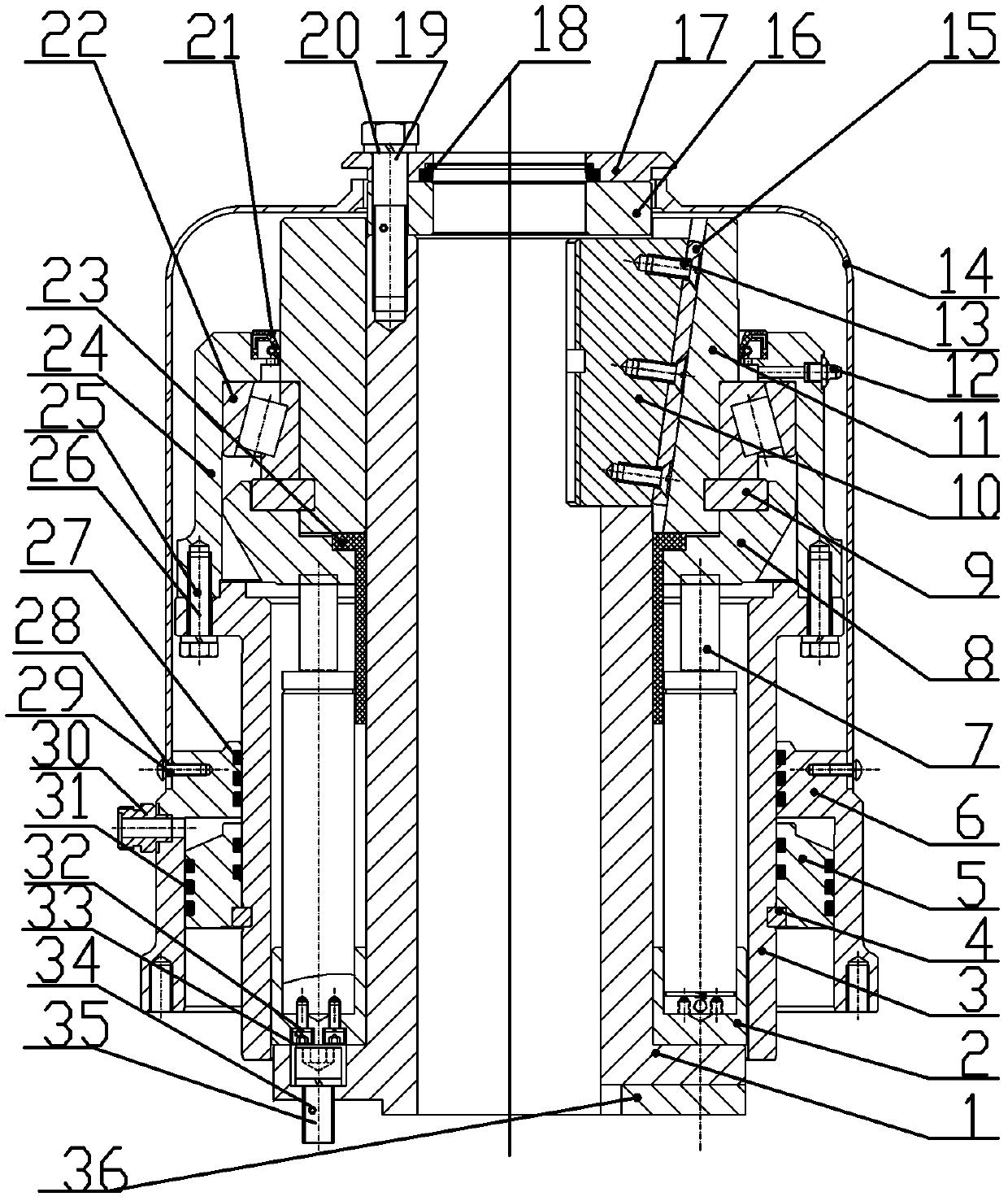

[0009] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

[0010] The present invention mainly includes a piston rod 3, a piston 5, a cylinder 6 and a chuck upper shell 24, the piston rod 3 is mounted on the chuck upper shell 24 through a washer 25 and a bolt 26, and the cylinder 6 is sleeved on the piston rod 3 On the outer ring, the piston 5 is located in the piston chamber between the piston rod 3 and the cylinder 6, the piston 5 is fixed on the piston rod 3 through the first key 4, and the slip seat 1, spring seat 2. Nitrogen gas spring 7 and slips 10, the piston rod 3 and the inner ring of the chuck upper shell 24 are installed with a slip seat 1, and the spring seat 2 is fixed by a washer 34 and a screw 35 on the end surface of the lower flange of the slip seat 1 The lower end of the nitrogen spring 7 is fixed on the spring seat 2 through the washer 32 and the screw 33; the first pressure plate 8 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com