Power generation system capable of jointly using sensible heat of raw gas of coke oven and waste heat of waste smoke

A technology of waste flue gas and raw coal gas, which is applied in the heating of coke ovens, coke ovens, and carbonization gas discharge devices, etc., and can solve the problems of poor economy of waste flue gas waste heat recovery projects, large investment in waste heat systems, and large investment in waste heat recovery, etc. problems, to achieve the effect of expanding steam utilization channels and improving economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the purpose, technical solutions and advantages of the present invention clearer, the embodiments of the present invention are further described in detail:

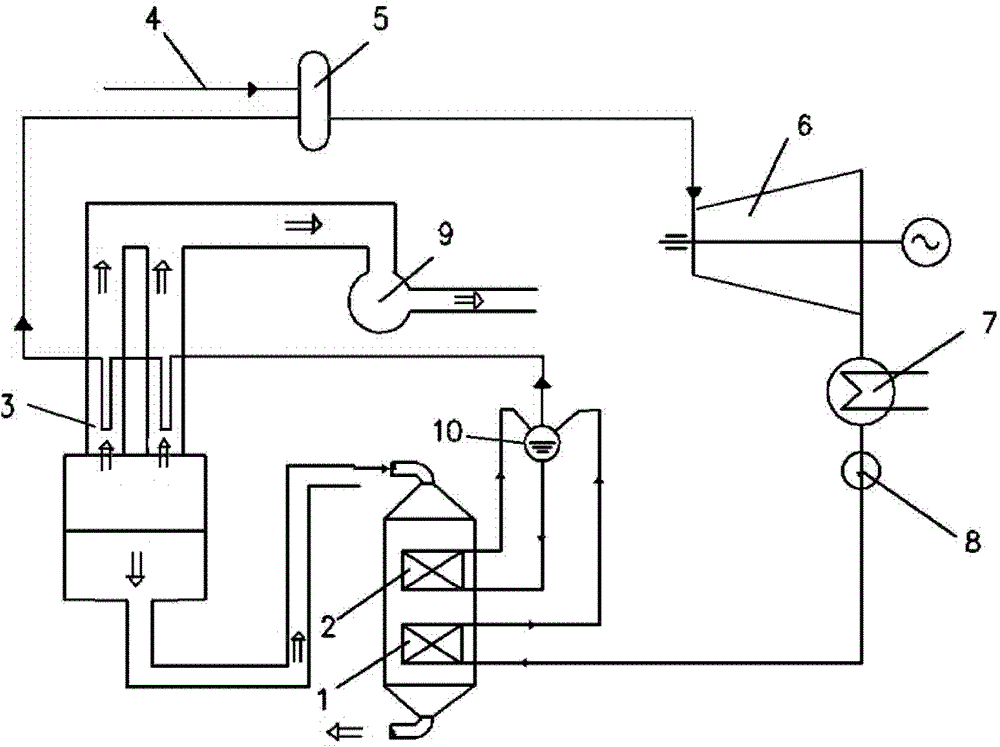

[0019] This embodiment provides a power generation system that jointly utilizes the sensible heat of coke oven raw gas and the waste heat of waste flue gas.

[0020] The exhaust gas system is used to lead the coke oven exhaust gas through the coke oven flue into the waste heat boiler system;

[0021] The coke oven exhaust gas is drawn from the coke oven flue, enters the waste heat boiler, passes through the waste heat boiler evaporator, waste heat boiler economizer, and then returns to the original exhaust system of the coke oven through the boiler outlet through the induced draft fan.

[0022] The raw gas system uses low-pressure steam as the cooling medium of coke oven raw gas to absorb the sensible heat of raw gas;

[0023] Coke oven raw gas collects at the top of the coke oven and enters the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com