Indoor evaluation method for antifouling properties of foul-release antifouling coatings

A technology of antifouling performance and antifouling coating, which is applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problem of large error in evaluation results, evaluation of antifouling performance of hard-to-foul release antifouling materials, Low data reliability and other issues, to achieve fast evaluation, high reliability, and good correlation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Example 1: Preparation of Diatom Suspension for Evaluation

[0012] In this embodiment, the diatoms are first placed in the F / 2 medium, put into an artificial climate box for cultivation, gently shake the Erlenmeyer flask 3 to 4 times a day, and measure the concentration of the algae liquid with a hemocytometer under an optical microscope. When the concentration of algae solution reaches 1×10 6 Each / mL, put the sterilized magnetite into the conical flask, peel off and disperse the diatoms attached to the bottom of the conical flask by low-speed magnetic stirring, and filter through a 300-mesh sieve to make the silicon in the diatom suspension The algae are in a single-cell state, and finally the density of the diatom suspension is adjusted to 1×10 with sterilized seawater. 5 individual / mL.

Embodiment 2

[0013] Example 2: Preparation of Ulva spore suspension for evaluation

[0014] In this example, several strains of algae are first selected and placed in a triangular flask filled with sterilized seawater for aerated culture. The water temperature is controlled at 20°C, and the light is continuously illuminated for 15 hours. Ulva spore suspension, and adjust the concentration of Ulva spores to 1×10 with sterile seawater 6 individual / mL.

Embodiment 3

[0015] Example 3: Evaluation of Antifouling Performance of Fouling Release Coatings on Diatoms

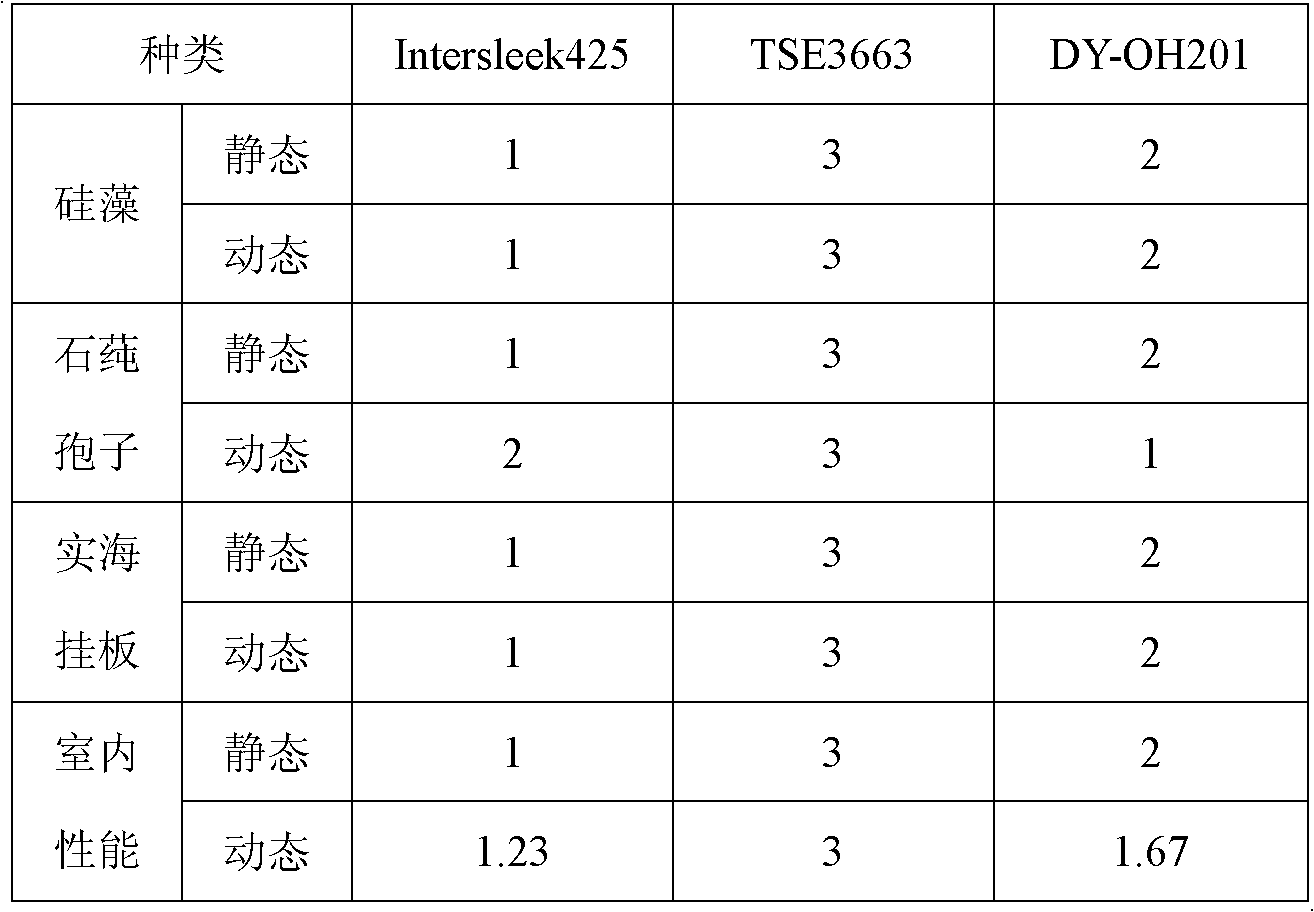

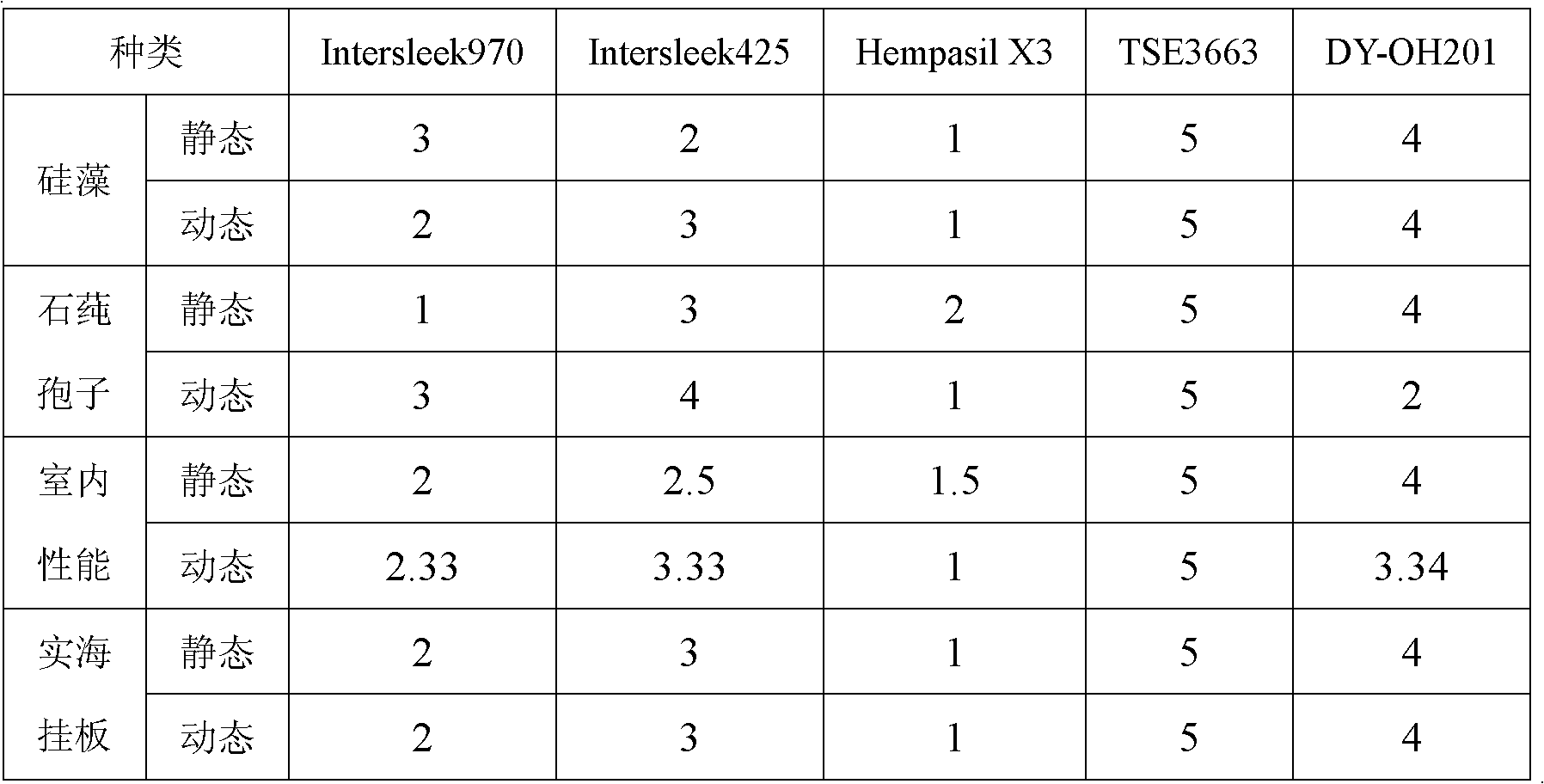

[0016] In this example, three kinds of fouling-release coating samples (Intersleek425, TSE3663 and DY-OH201) were put into the diatom suspension prepared in Example 1, and were statically attached for 3 hours at 20°C; Gently shake back and forth several times in sterilized seawater to remove unattached diatoms, count the number of diatoms attached to the surface of the sample under an optical microscope, and use the number of static attachments of diatoms to characterize the static antifouling performance of the antifouling coating and carry out Sorting, see Table 1 for specific data; quickly fix the sample plate counted in the static adhesion experiment on the rotary scouring device, and remove the sample plate after scouring at a scouring speed of 2m / s for 5min. The algae were counted, the removal rate of diatoms was calculated, and the dynamic antifouling performance of the anti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com