Gas explosibility identification method of mine gas tube bundle monitoring system

A technology for monitoring and identifying methods of bundled tubes, which is applied to measurement devices, mining devices, mining equipment, etc., can solve problems such as poor real-time performance and inability to systematically judge fire hazards, and achieve long service life, timely technical support, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

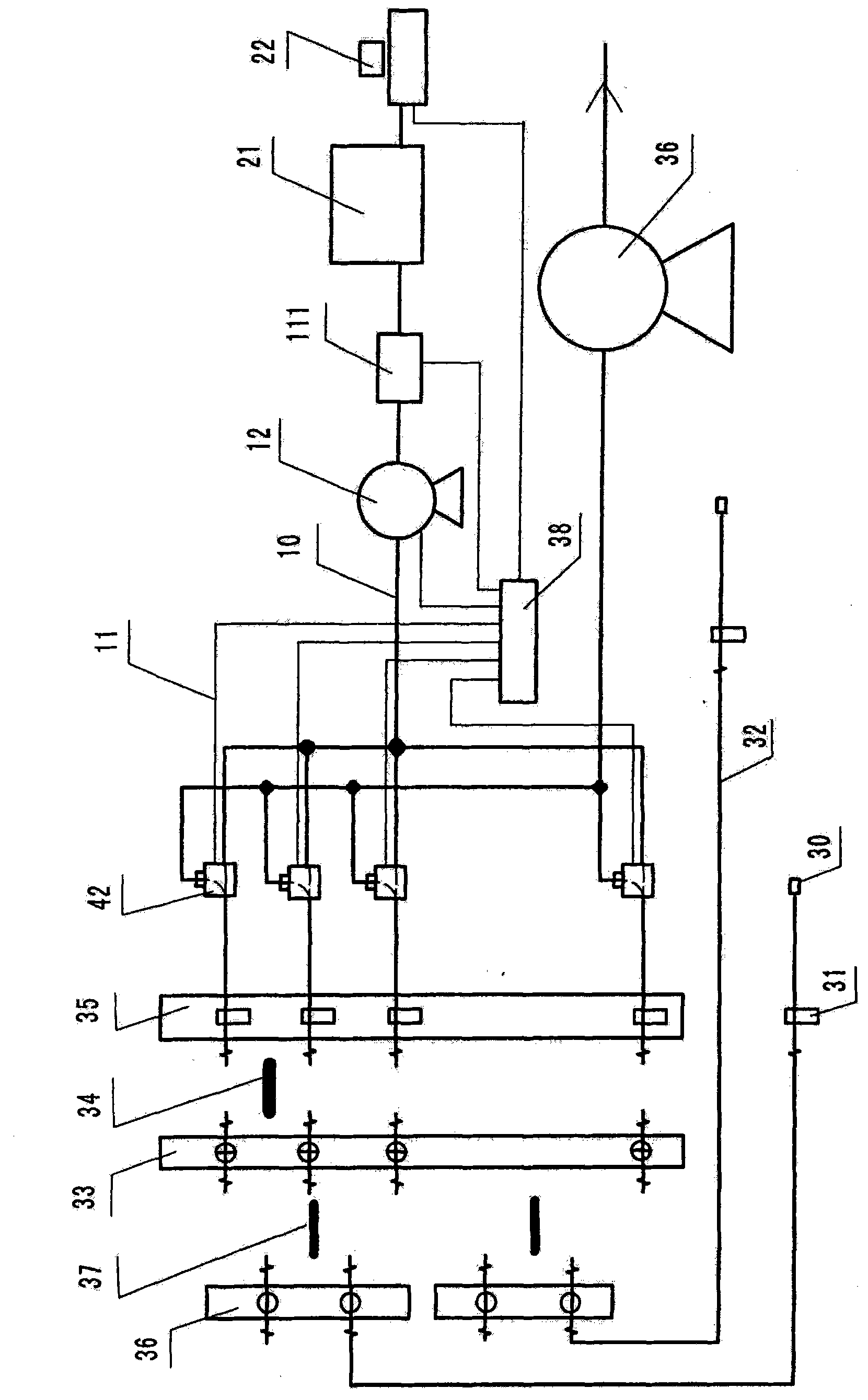

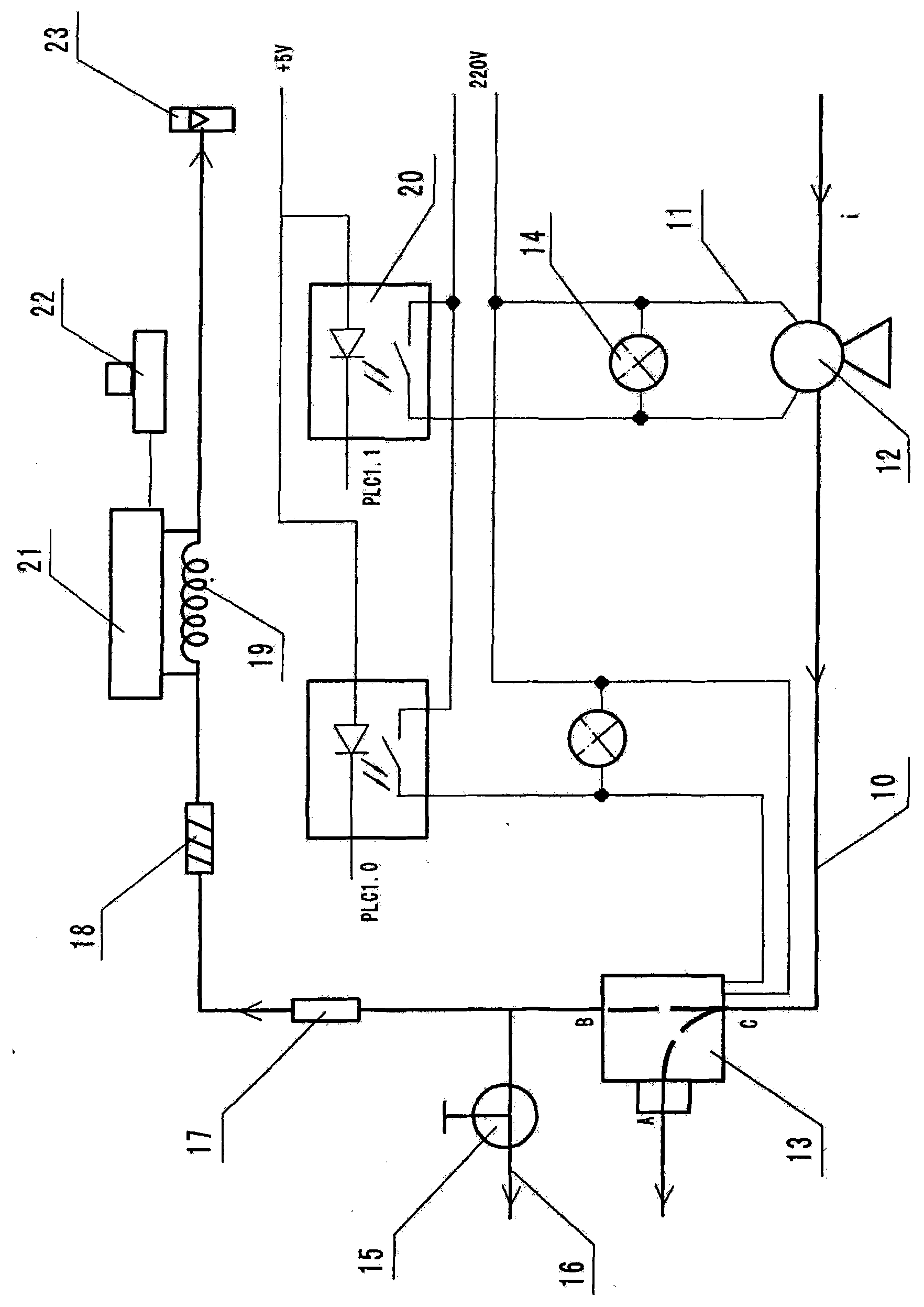

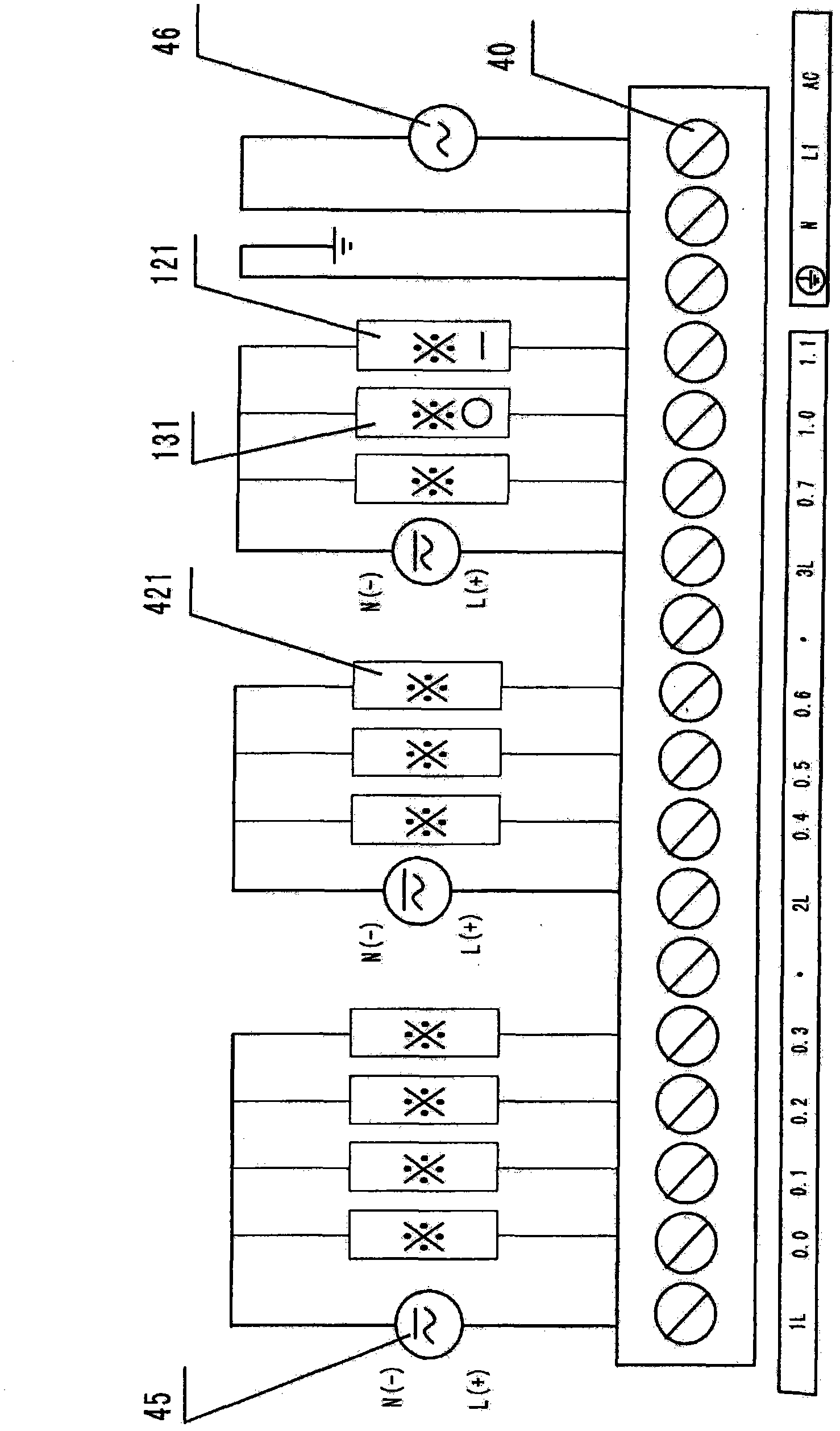

[0121] For a first example, see figure 1 , figure 2 , image 3 , Figure 4 , a mine gas bundle tube monitoring system, which includes a single-core bundle tube 32 with a single-way gas-water separator 31 in the middle of several end-fixed samplers 30 connected to the branch box 36, and then through the branch tube bundle tube cable 37 Connected to the connection box 33, from the connection box 33, the main bundle tube tube cable 34 composed of several single-core bundle tubes is connected to the gas-water separator box 35, and then the gas flow controlled by the programmable controller——PLC38 through the electrical control circuit 11 Circuit switch solenoid valve 42 and air suction pump 39 form an automatic sampling device, which is characterized in that it also includes an oil-free gas injection pump 12 controlled by an automatic sampling pipeline 10 connected to a programmable controller and a switch solenoid valve 13, with a venting end 16 The split needle valve 15, dr...

no. 2 example

[0123] For a second embodiment, see figure 1 , figure 2 , image 3 , Figure 4 , a mine gas bundle tube monitoring system, which includes a single-core bundle tube 32 with a single-way gas-water separator 31 in the middle of several end-fixed samplers 30 connected to the branch box 36, and then through the branch tube bundle tube cable 37 Connected to the connection box 33, from the connection box 33, the main bundle tube tube cable 34 composed of several single-core bundle tubes is connected to the gas-water separator box 35, and then the gas flow controlled by the programmable controller——PLC38 through the electrical control circuit 11 Circuit switch solenoid valve 42 and air suction pump 39 form an automatic sampling device, which is characterized in that it also includes an oil-free gas injection pump 12 controlled by an automatic sampling pipeline 10 connected to a programmable controller and a switch solenoid valve 13, with a venting end 16 The split needle valve 15...

no. 3 example

[0129] For a third embodiment, see Image 6 , Figure 8 , figure 1 , a gas explosiveness identification method, including the explosion triangle method (X 1 , Y 1 ) is the L coordinate of the 100% lower limit point, (X u , Y u ) is the U coordinate of the 100% upper limit point, (X S , Y S ) is the S coordinate of the 100% critical point, which is characterized by (X 1 50,Y 1 50) is the 50% lower limit point L 50 Coordinates, (X u 50,Y u 50) is the 50% upper limit point U 50 Coordinates, (X S 50,Y S 50) is the 50% critical point S 50 Coordinates, (X 1 75,Y 1 75) is the 75% lower limit point L 75 Coordinates, (X u 75,Y u 75) is the 75% upper limit point U 75 Coordinates, (X S 75,Y S 75) is the 75% critical point S 75 coordinate,

[0130] x 1 50=X 1 / 2,Y 1 50=(20.93-Y 1 ) / 2+Y 1

[0131] x u 50=(100-X u ) / 2+X u , Y u 50=Y u / 2

[0132] x S 50=X S / 2,Y S 50=Y S / 2

[0133] x 1 75=X 1 50+X 1 50 / 2, Y 1 75=(20.93-Y 1 50)-Y 1 50 / 2

[013...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com