High temperature (200 DEG C)-resistant tightly wrapped optical fiber and preparation process thereof

A technology of tightly wrapped optical fiber and high temperature resistance, which is applied in the direction of clad optical fiber, multi-layer core/clad optical fiber, etc., to achieve the effects of high flame retardancy, good adhesion, and stable optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

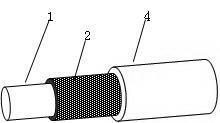

[0009] Control attached figure 1 The structure is that the periphery of the core 1 is a polyimide coating layer 2; the periphery of the polyimide coating layer 2 is a tight outer layer 4 of cross-linked ethylene tetrafluoroethylene copolymer X-ETFE.

[0010] Its preparation process: the fiber core is divided into single-mode and multi-mode, the single-mode structure is 9 / 125 μm, the multi-mode structure is 50 / 125 μm or 62.5 / 125 μm; the coating layer is coated with polyimide, and the polyimide-coated The temperature resistance grade is -65℃~+200℃, and the outer diameter of the coating layer is 155μm. The coating layer enables the tight-packed optical fiber to be laid and installed normally at -65℃; the tight-packed outer layer 4 is a single layer of high-temperature extruder Thin-wall extrusion cross-linked ethylene tetrafluoroethylene copolymer material X-ETFE, high temperature resistance 200 ℃.

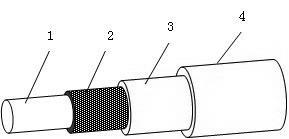

[0011] Control attached figure 2 , its structure is that the periphery of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com