Deep-ultraviolet lithography illumination system

A lighting system and deep ultraviolet light technology, applied in the field of high-resolution lithography, can solve the problems of complex technology, high price, and difficult research of lithography technology, and achieve good lighting effects, simple results, and avoid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

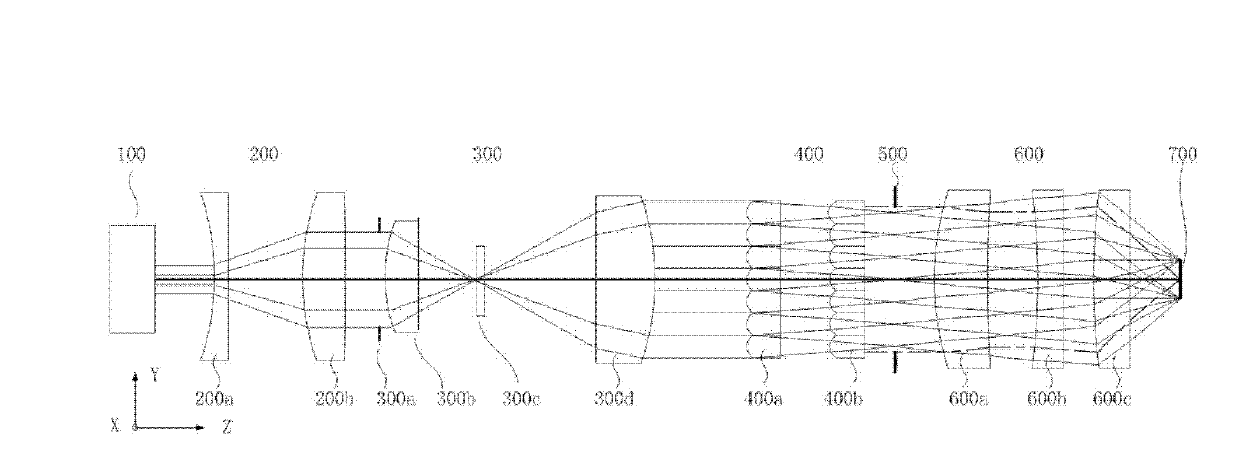

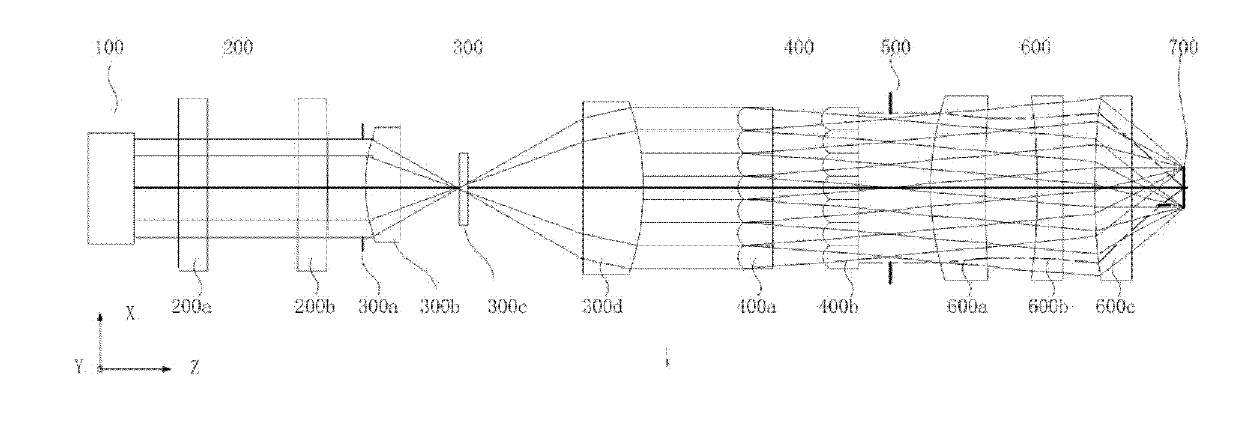

[0035] The lithography illumination system of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0036] Predefinition of the coordinate system: the direction of the laser beam is taken as the Z axis, and the coordinate system (X, Y, Z) is established according to the principle of the left-handed coordinate system.

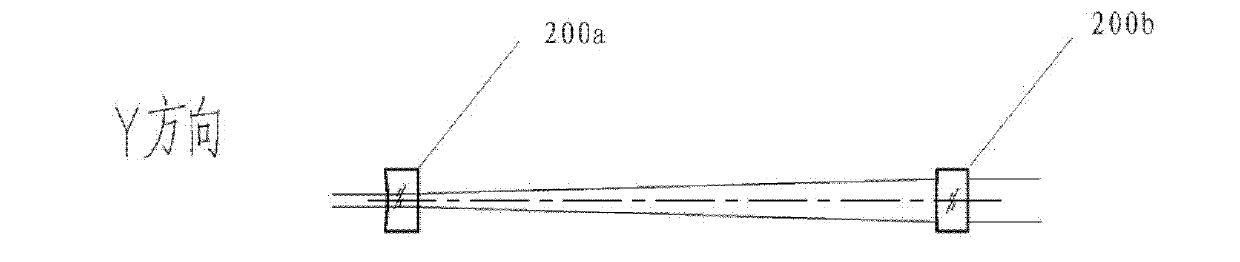

[0037] Such as Figure 1A with 1B As shown, the deep ultraviolet lithography illumination system of the present invention includes a deep ultraviolet laser light source, a cylindrical beam expander mirror system, a spherical beam expander mirror system, a compound eye uniform photon system, a condenser mirror system, a circular diaphragm and an aperture diaphragm; The sequence relationship of each component along the forward direction of the laser light path is: deep ultraviolet laser light source, cylindrical beam expander mirror system, circular diaphragm, spherical beam expander mirror system, compoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com