Encapsulated inductor and assembly process thereof

An assembly process, inductance technology, applied in the direction of inductance/transformer/magnet manufacturing, transformer/inductor coil/winding/connection, circuit, etc., can solve the problem of manufacturing, assembly, transportation, increase in volume and weight of inductance, and explosion of inductance and other problems, to achieve the effect of meeting the needs of high-pressure work, low processing and manufacturing costs, and firm structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

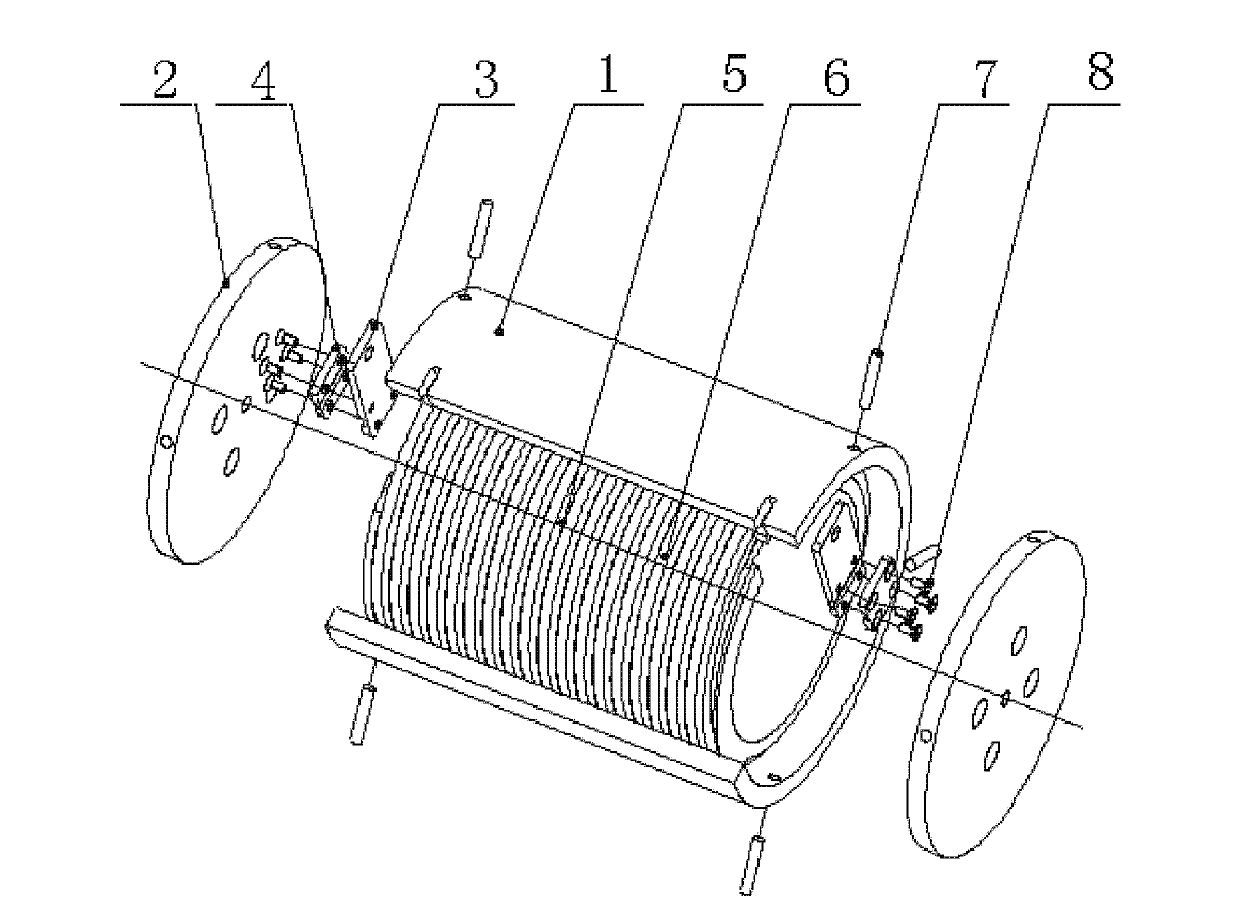

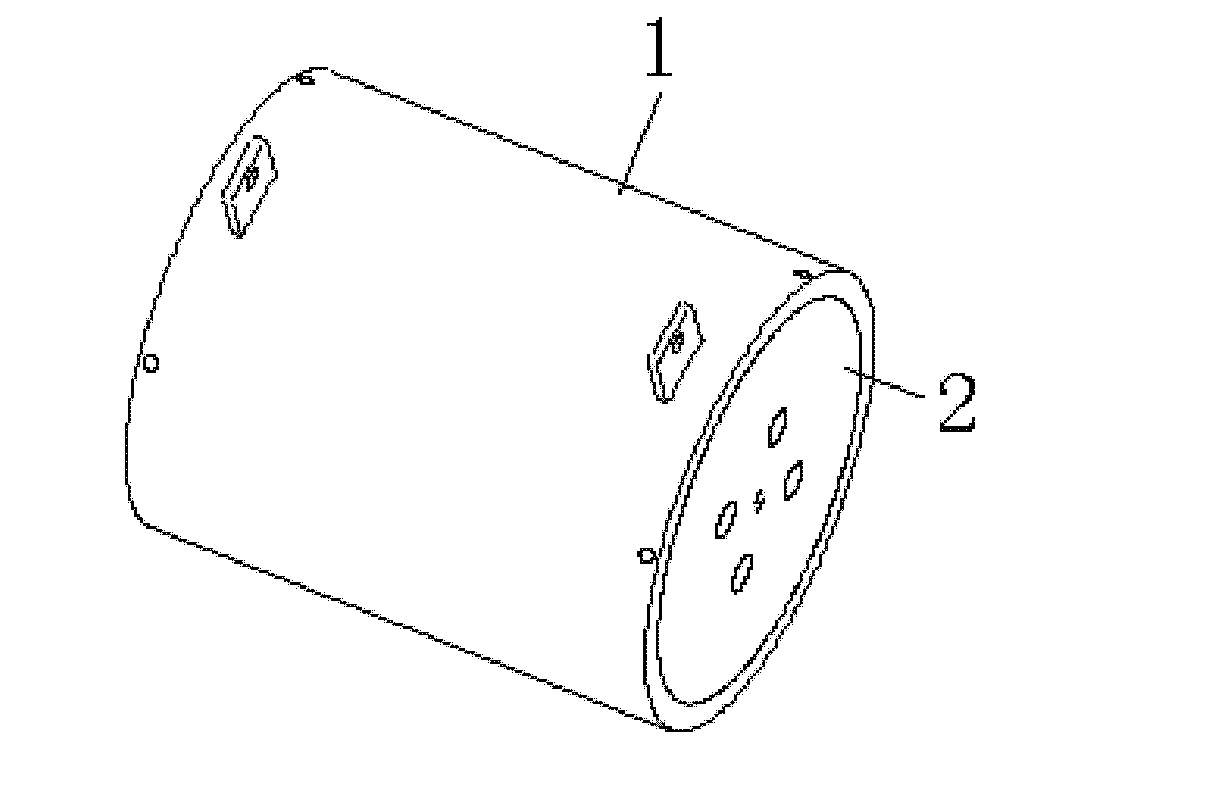

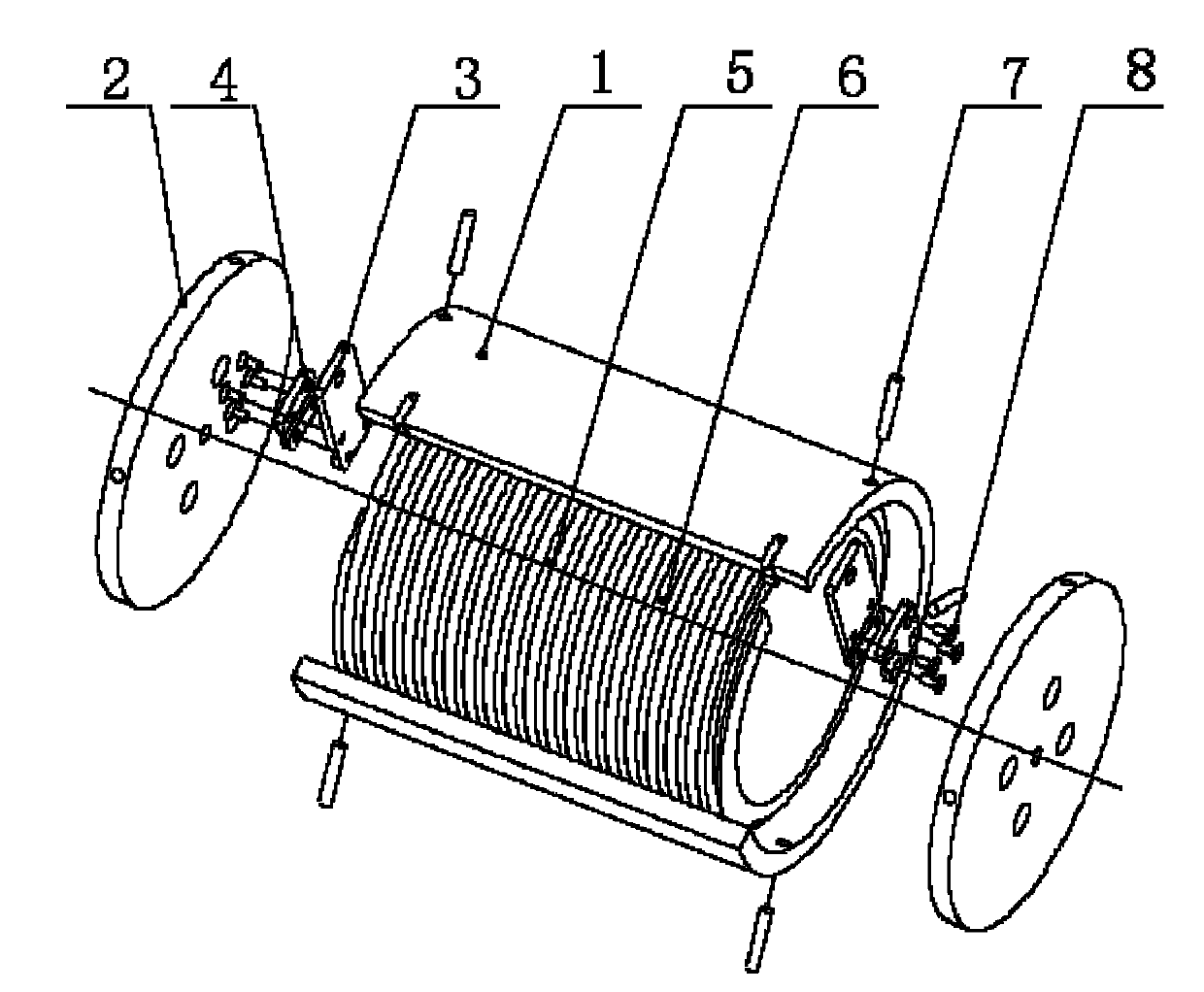

[0024] Such as figure 1 and figure 2 As shown, the potting inductor includes a cylindrical skeleton 6 and a cylindrical protective cover 1 wound with a copper coil 5 on the surface, the skeleton 6 is located inside the protective cover 1, and the skeleton 6 is concentric with the protective cover 1; The cover 1 is provided with an outlet for the copper wire of the copper coil 5 to protrude; the two ends of the inner frame 6 of the protective cover 1 are respectively provided with a bus bar 3, and the two ends of the copper coil 5 are respectively stuck on the bus bar 3, There is a wire groove on the busbar 3; an end cover plate 2 is provided on both ends of the protective cover 1, and a pressure plate 4 is provided between the end cover plate 2 and the bus bar 3, and the pressure plate 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com