Power supply connecting device of double-end gas discharge lamp

A gas discharge lamp and power supply connection technology, applied to discharge lamps, discharge tubes, circuits, etc., can solve the problems of easy dispersal, unsafe use, and glass breakage, etc., to achieve convenient installation and use, prolong service life, and reduce heat generation The effect of the phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

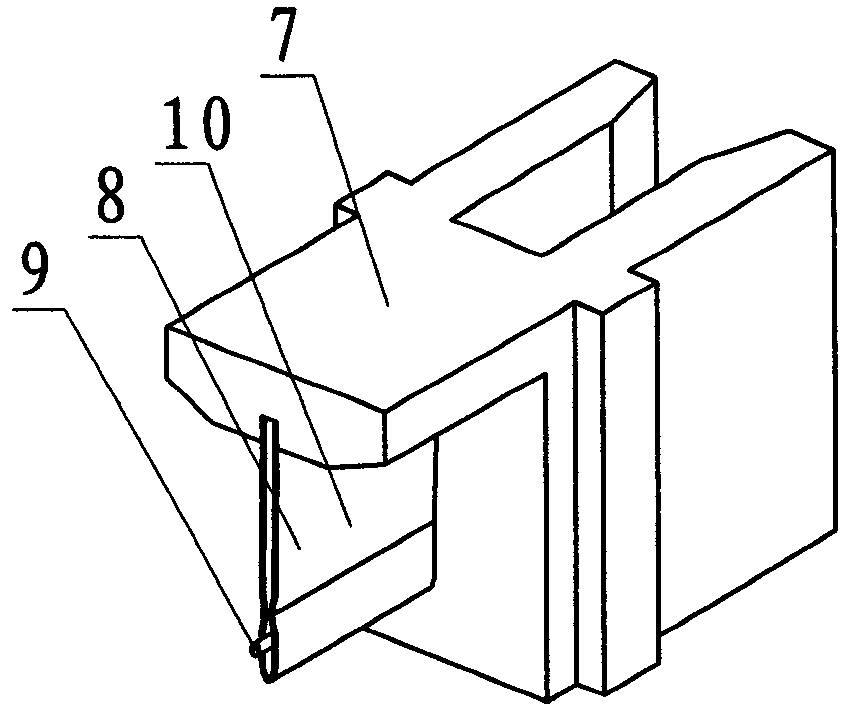

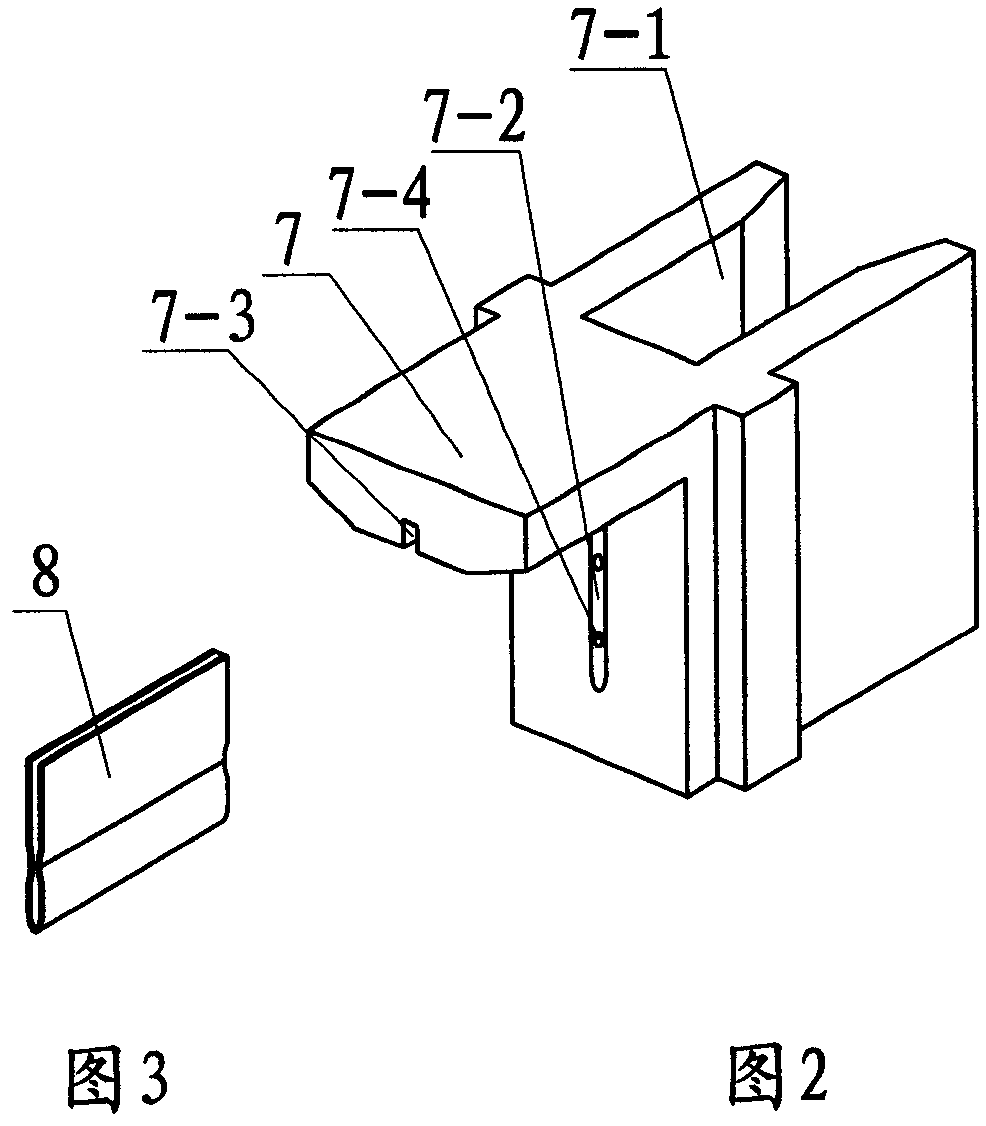

[0013] The lead-out wire clip 10 is made of a stainless steel sheet and has a clip 8 with indentations on both surfaces. The outer end of the lead-out wire 9 is clamped and fixed in the middle gap to form a whole. Add spot welding to the clip 8 on the outer surface of the lead wire, so that the lead wire is completely fixed on the clip, such as figure 1 , image 3 , Figure 5 shown.

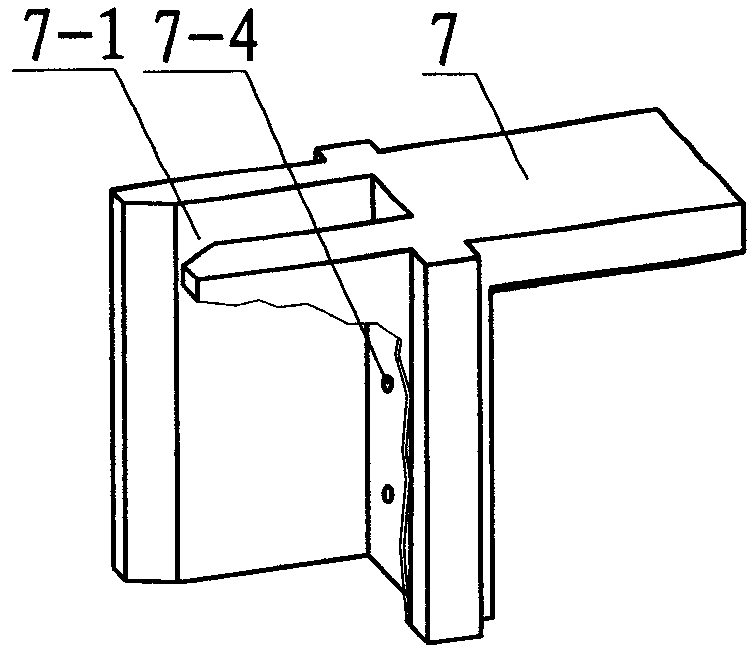

[0014] Porcelain head 7 is made of insulating material with high temperature resistance, moisture resistance and high dielectric strength. There are short grooves 7-2 on the left vertical surface of the porcelain head, long grooves 7-1 on the right surface, and the bottom surface of the long grooves Two threading holes 7-4 are arranged on the vertical surface and communicate with the short groove 7-2, and the upper surface has a lower groove 7-3, such as figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com