Reactive distillation unpowered circulation technology and device

A technology of power cycle and reactive distillation, which is applied in the field of reactive distillation, can solve the problems of large-scale equipment, difficult operation, high maintenance costs, etc., and achieve the effects of less heat, positive enterprise benefits, and enhanced circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

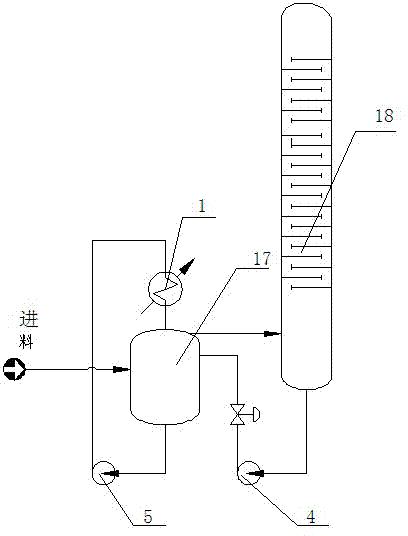

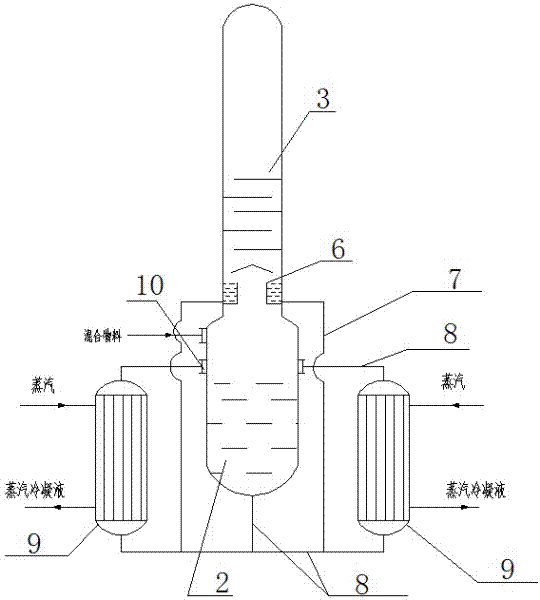

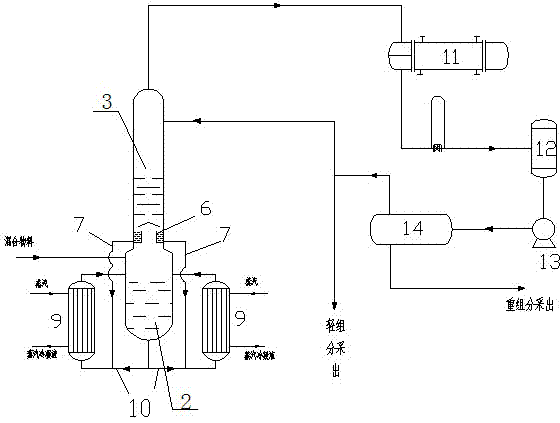

[0027] The technical solution of the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

[0028] Take the production of butyl acetate as an example.

[0029] In the rectification tower system, butanol and acetic acid proportioned according to the reaction equation pass through the raw material preheater 16 (E3105), and are added from the upper part of the rectification tower tank (T3101), and the liquid reaction liquid containing catalyst and raw materials is in the rectification tower The esterification reaction takes place in the tower kettle 2. The final butyl acetate product material provides a heat source for the raw material preheater 16 (E3105) to heat the mixed raw material to save energy.

[0030] Under the action of potential difference, self-gravity and siphon force, the material in the natural convection pipe at the bottom of the distillation column 2 and the condensate in the overflow weir 6 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com