Method for producing low-sulfur gasoline by non-hydroforming sulfur and alcohol removal

A non-hydrogen sweetening and sweetening technology, which is applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve the problem of reducing the total sulfur of the product, so as to improve the stripping effect and avoid the loss of octane number of the product , the effect of improving the reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

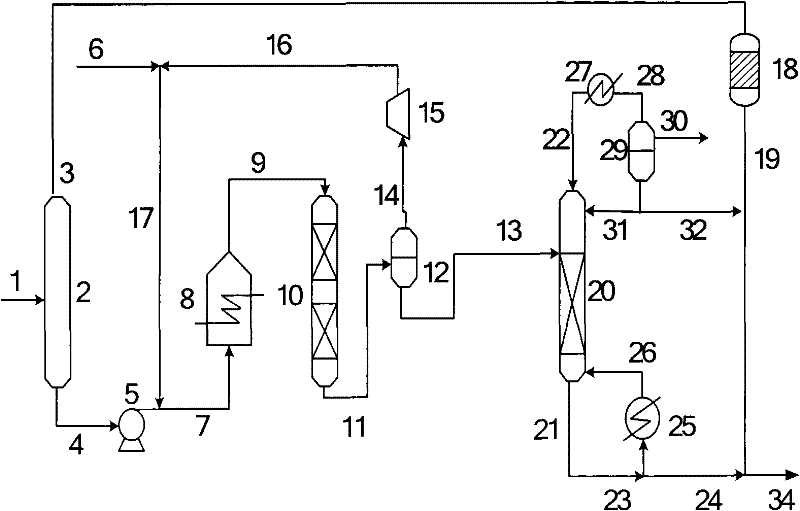

Method used

Image

Examples

Embodiment

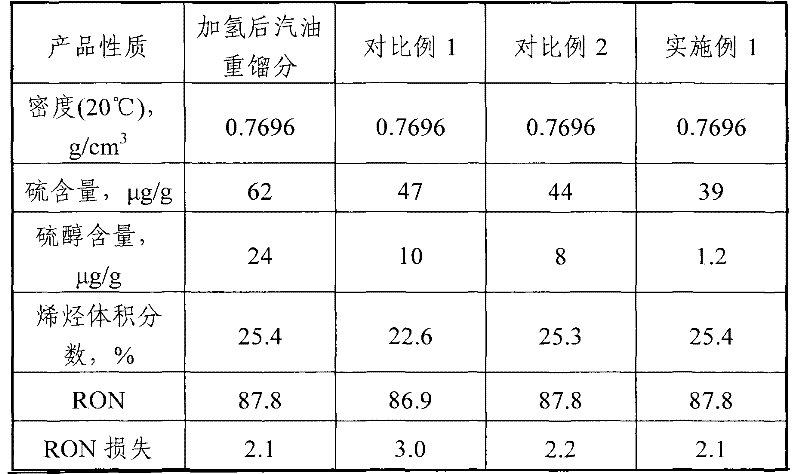

[0041] The processes of gasoline fractionation and heavy gasoline fraction hydrodesulfurization are the same as in Comparative Example 1. The stripping tower is used as a countercurrent reactor, and the configuration is based on the stripping tower in Comparative Example 2, and a Φ3mm Raschig ceramic ring filler is filled above the feed section. The heavy gasoline product after hydrogenation is introduced into the stripping tower, the feed rate of the device is 500 g / h, the operating pressure of the stripping tower is 1.4Mpa, nitrogen is fed into the bottom of the tower as an additional stripping medium, and the feed rate of nitrogen is 3L / h. The average temperature of the catalyst bed below the feed is 240°C, and the temperature of the tower bottom is 280°C. The top product of the stripping tower is partially refluxed, with a reflux ratio of 0.3, and partially discharged, with a discharge rate of 150 g / h. The properties of the product after sweetening are shown in Table 2. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com