Dust discharging and preventing as well as cooling device for inner hole plasma spraying

A cooling device and plasma technology, applied in the fields of dust exhaust, dust prevention, and cooling devices, can solve problems such as difficulty in dust discharge, high ambient temperature, and polluted coatings, so as to reduce airflow interference and dust pollution, ensure reliability, and reduce dust pollution. The effect of small thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The dust discharge, dust prevention and cooling device for inner hole plasma spraying of the present invention will be further described in detail below in conjunction with the accompanying drawings.

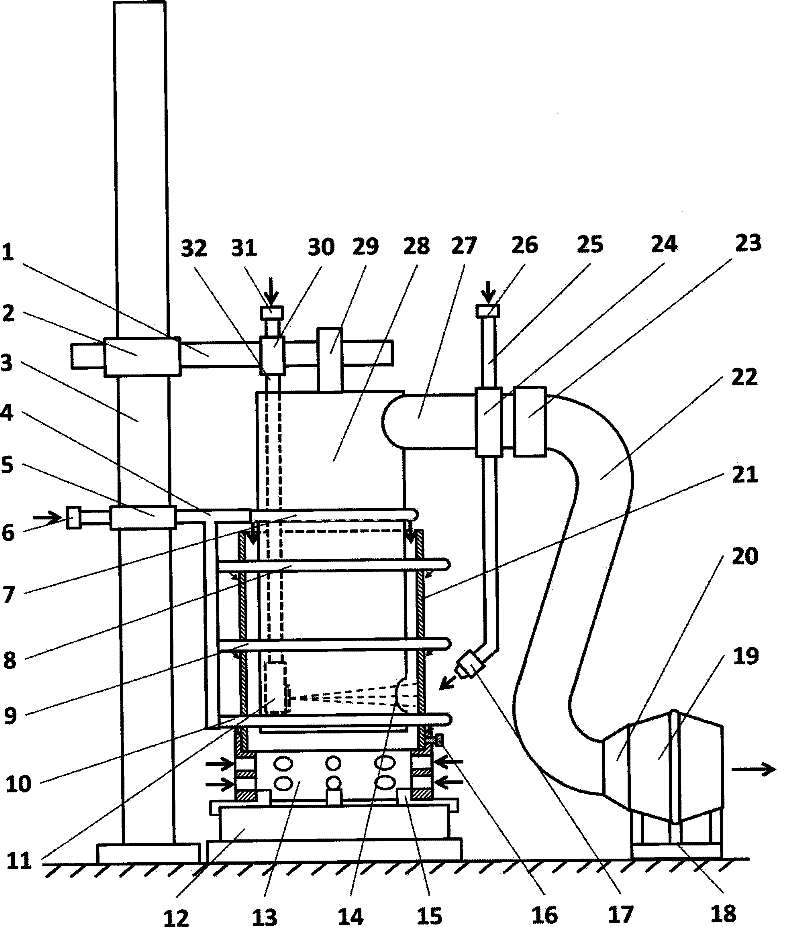

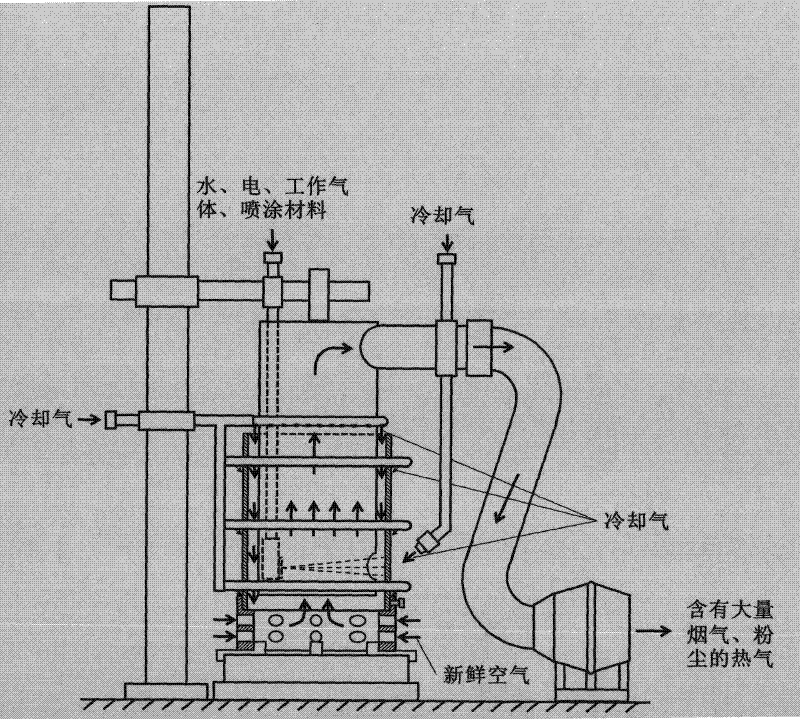

[0031] like figure 1 As shown, the present invention proposes a dust discharge, dust prevention and cooling device used in an inner hole plasma spraying device. The inner hole plasma spraying device mainly includes a lifting mechanism, an inner hole spray gun 11 and a rotating mechanism 12, and the inner hole spray gun 11 Fixed on the lifting mechanism to move vertically up and down, the workpiece 21 with the inner hole to be sprayed is fixed on the rotating mechanism 12 for rotational movement, and the inner hole spray gun 11 extends into the inner cavity of the workpiece 21 to achieve uniform coating on the inner wall of the inner hole workpiece cover; the dust discharge, dustproof and cooling device of the present invention are mainly composed of a suction dust-proof t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com