Moveable slip form car and method for manufacturing drainage blind ditch by using moveable slip form car

A technology of drainage blind ditch and moving pulley, which is applied in the field of mobile sliding form trolley to make drainage blind ditch, which can solve the problems of hidden safety hazards, large deformation loss, serious edge collapse, etc., to reduce labor and material consumption and reduce friction Force, drag reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

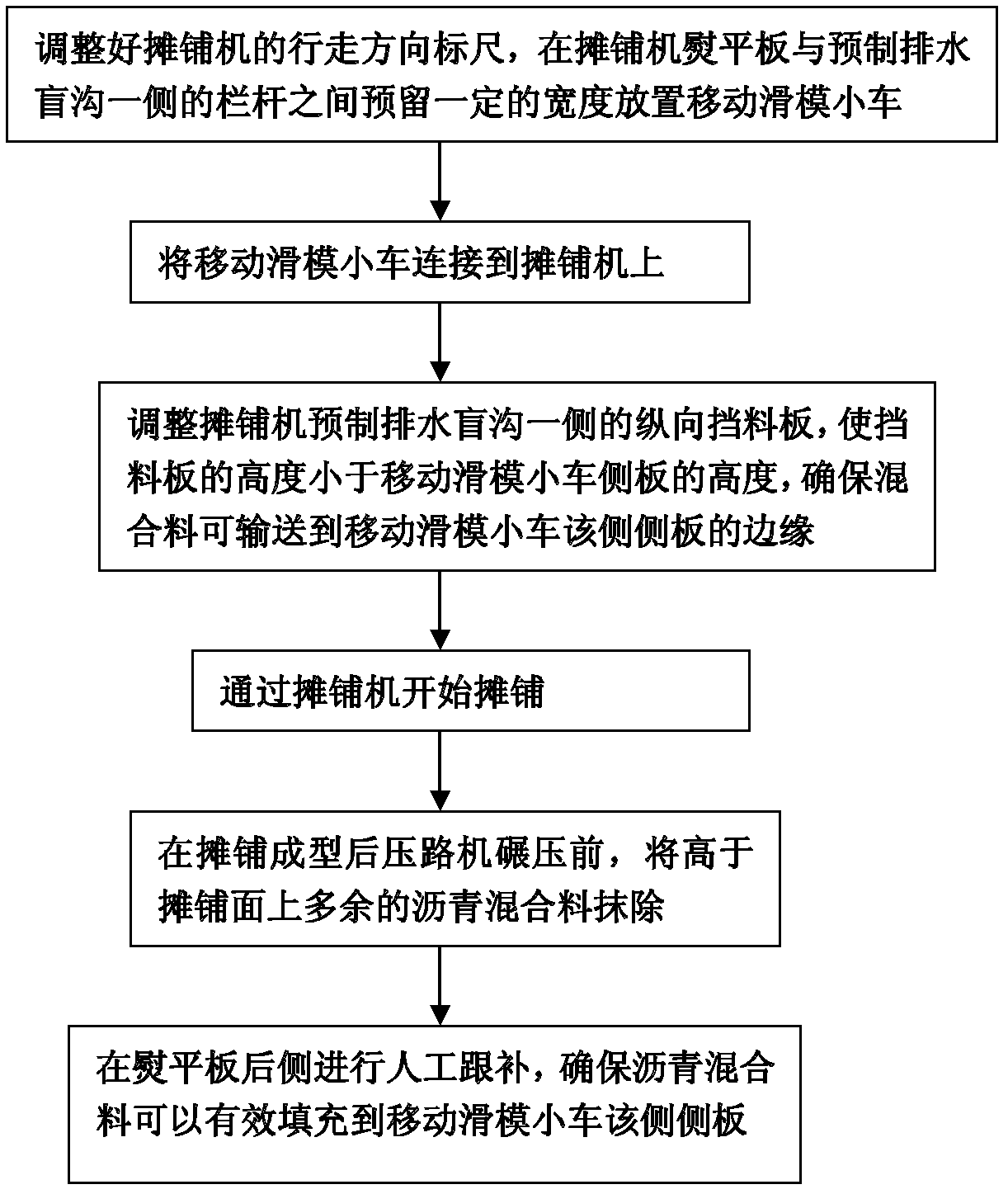

[0037] Example: The total length of the blind drainage ditch deck needs to be made is 30,000 meters. According to the average paving progress of 1,000 meters, the 30,000-meter bridge deck paving needs 30 working days to complete, and the labor cost is 100 yuan / person.day, 10# The price of channel steel is 50 yuan / m, and the price of wood is 5 yuan / m. The consumption rate of channel steel is calculated as 15%, and the consumption of wood is calculated as 50%. It is 500 yuan / time, and the number of material transfers is 5 times.

[0038] The cost statistics of the 4 blind ditch production methods are as follows:

[0039] Types of Material loss Accumulated labor costs Material forwarding fee total cost Remark reservation method 0 100×30×2=6000 0 6000 2 people cooperate Channel steel method 150000 100×40×6=24000 500×5=2500 176500 6 people cooperate wooden method 50000 100×40×10=40000 500×5=2500 92500 10 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com