Three-dimensional model testing system of deep mine construction engineering

A technology for construction engineering and three-dimensional models, applied in teaching models, instruments, educational tools, etc., can solve the problems of inability to simulate blasting engineering, insufficient flexibility of test equipment, and small deformation of test benches, and achieve the effect of convenient installation and disassembly of test samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

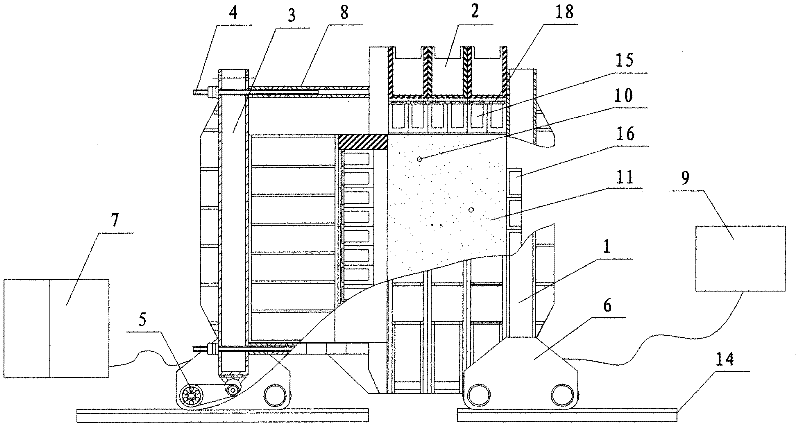

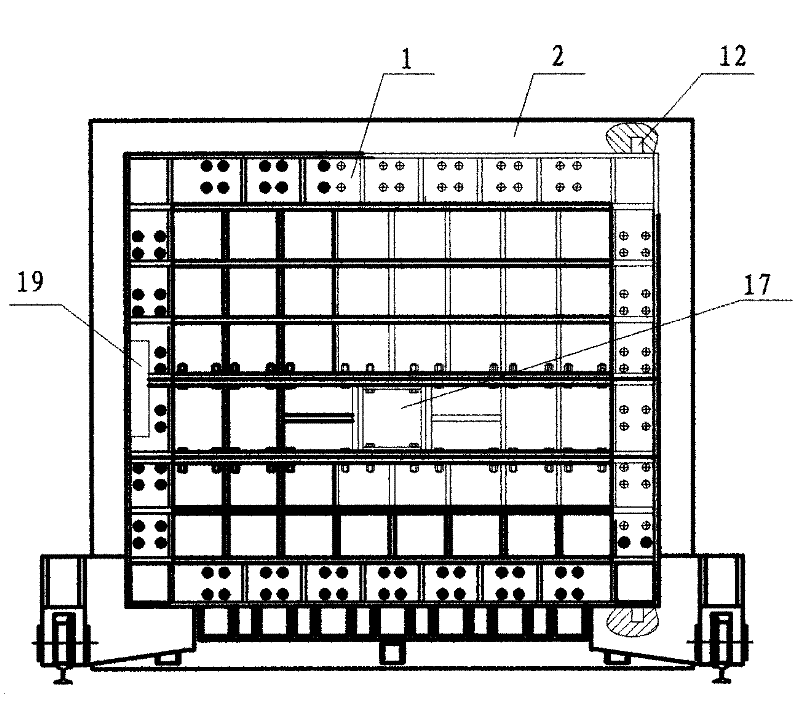

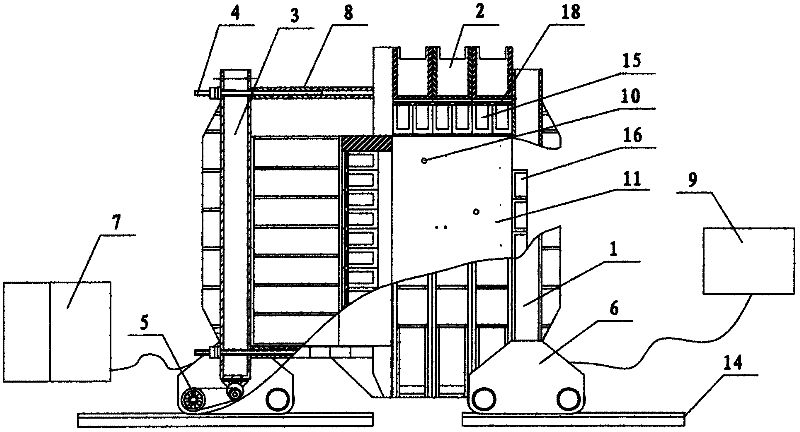

[0028] The central idea of the present invention is to form a relatively closed three-dimensional simulation space in the simulation test system by using the "back"-shaped main frame body and the door-type reaction force frame and rear loading frame correspondingly arranged at the front and rear ends. Simulate the stress and deformation of the test samples in various simulated environments and load states in the simulated space, and obtain the test data of the test samples in the simulated environment, providing theoretical and data basis for the actual construction process of deep mines, and ensuring that the construction process can Safe, smooth and orderly.

[0029] Attached below figure 1 , figure 2 The present invention is further described:

[0030] The three-dimensional model test system for deep mine construction engineering according to the present invention includes a hydraulic loading system, a control system 9, a data monitoring system 10 and a reaction force ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com