Resin composition for semiconductor encapsulation, and semiconductor device

一种树脂组合物、半导体的技术,应用在半导体器件、半导体/固态器件零部件、电固体器件等方向,能够解决运送不良、耐焊锡性、耐燃性、成型性特性受损、成品率下降等问题,达到可靠性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0232] The following components were mixed at room temperature using a mixer, melted and kneaded with a heating roll at 80° C. to 100° C., cooled, and pulverized to obtain a resin composition for semiconductor encapsulation.

[0233]

[0234] The following items were evaluated about the obtained resin composition for semiconductor encapsulation. The evaluation results are shown in Table 2.

[0235] (evaluation item)

[0236] Helical fluidity: Using a low-pressure transfer molding machine (KOHTAKI Seiki Co., Ltd., KTS-15), in a mold for measuring helical fluidity based on EMMI-1-66 at 175°C, injection pressure 6.9MPa, The resin composition was injected under the condition of a pressing time of 120 seconds, and the flow length was measured. The helical fluidity is a parameter of fluidity, and the larger the value, the better the fluidity. The unit is cm. The resin composition obtained in Example 1 was 121 cm and showed good fluidity.

[0237] Flame resistance: Using a lo...

Embodiment 2~20、 comparative example 1~5

[0243] According to the formulations in Tables 2 to 5, a resin composition was produced in the same manner as in Example 1, and evaluated in the same manner as in Example 1 (the numerical units of the components in Tables 2 to 5 are parts by mass, as in Example 1) . The evaluation results are shown in Tables 2 to 5.

[0244] [Table 2]

[0245] Table 2

[0246]

[0247] [table 3]

[0248] table 3

[0249]

[0250] [Table 4]

[0251] Table 4

[0252]

[0253] [table 5]

[0254] table 5

[0255]

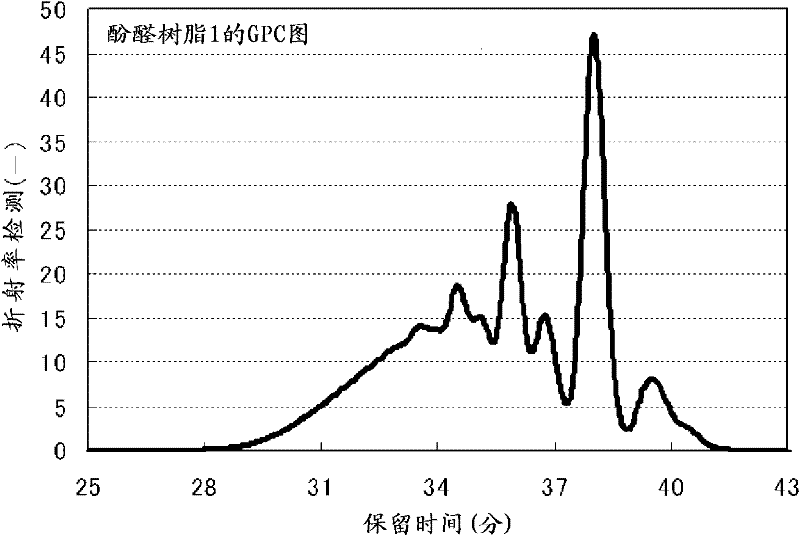

[0256] Embodiments 1 to 20 are compositions comprising a phenolic resin (A), an epoxy resin (B) and an inorganic filler (C), wherein the phenolic resin (A) comprises a structural unit represented by formula (1) and Component (A1) composed of a polymer of the structural unit represented by formula (2), these examples include compositions obtained by changing the compounding ratio of the structural unit of the phenolic resin (A), containing other The composition of cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com