A kind of method for catalytic oxidation of cyclic ketone by nano-β molecular sieve

A technology for the catalytic oxidation of cyclic ketones and beta molecular sieves by molecular sieves, applied in molecular sieve catalysts, chemical instruments and methods, oxidation preparation of carboxylic acids, etc. The problem is to achieve the effect of good catalytic oxidation activity and catalytic activity stability, high catalytic oxidation activity and activity stability, and overcoming the complex production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

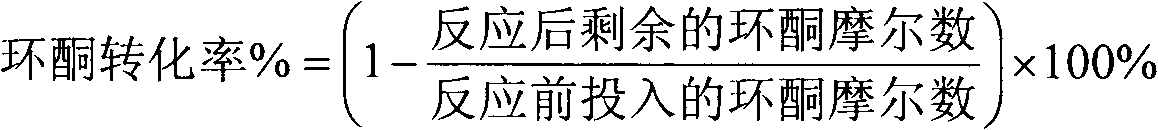

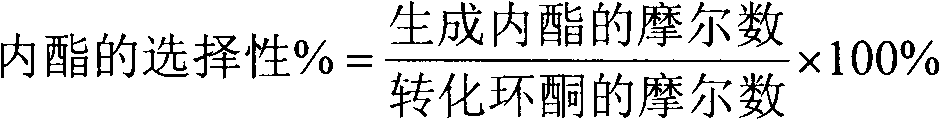

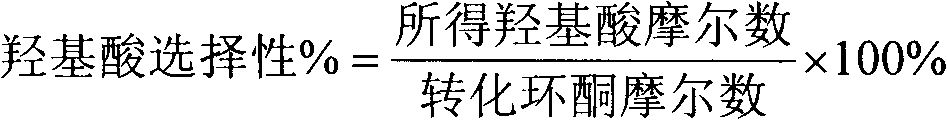

[0044] Take by weighing 2.3 grams of acid-eluted aluminum nano-beta-molecular sieves (the mass fraction of aluminum oxide is 1.2wt%) catalyst and be loaded in a 100ml three-necked flask, then add a magnetic stirrer, 19.63 grams of cyclohexanone, 3.6 grams of water and 23ml The concentration is 30% hydrogen peroxide, and the molar ratio of cyclohexanone to hydrogen peroxide is 1:1. The three-necked flask is placed on a temperature-controlled magnetic stirrer, and the upper part of the three-necked flask is condensed and refluxed with a condenser, and the magnetic stirrer and heating device are started to start the reaction. The reaction temperature was controlled at about 70°C. After 2 hours of reaction, the conversion rate of cyclohexanone was 20.65%, the selectivity of generating ε-caprolactone was 46.45%, the selectivity of 6-hydroxycaproic acid was 21.98%, and the Acid selectivity was 14.19%.

Embodiment 2

[0046] Take by weighing 2.44 grams of acid-eluted aluminum nano-beta-molecular sieves (the mass fraction of aluminum oxide is 2.3wt%) catalyst and be loaded in a 100ml three-necked flask, then add magnetic stirrer, 19.63 grams of cyclohexanone, 24 grams of acetone and 23ml The concentration is 30% hydrogen peroxide, and the molar ratio of cyclohexanone to hydrogen peroxide is 1:1. The three-necked flask is placed on a temperature-controlled magnetic stirrer, and the upper part of the three-necked flask is condensed and refluxed with a condenser, and the magnetic stirrer and heating device are started to start the reaction. The reaction temperature was controlled at about 60°C. After 3 hours of reaction, the conversion rate of cyclohexanone was 27.82%, the selectivity of ε-caprolactone was 94.65%, the selectivity of 6-hydroxycaproic acid was 1.98%, and the Acid selectivity was 0.72%.

Embodiment 3

[0048]Weigh 2.65 grams of acid-eluted aluminum nano-beta-molecular sieve catalyst (the mass fraction of aluminum oxide is 3.7wt%) and put it in a 100ml three-necked flask, then add a magnetic stirrer, 19.63 grams of cyclohexanone, and 18 grams of dioxane ring and 46ml concentration of 30% hydrogen peroxide, the molar ratio of cyclohexanone to hydrogen peroxide is 1:2. The three-necked flask is placed on a temperature-controlled magnetic stirrer, and the upper part of the three-necked flask is condensed and refluxed with a condenser, and the magnetic stirrer and heating device are started to start the reaction. The reaction temperature was controlled at about 72°C. After 4 hours of reaction, the conversion rate of cyclohexanone was 58.57%, the selectivity of generating ε-caprolactone was 98.18%, the selectivity of 6-hydroxycaproic acid was 0.68%, and the Acid selectivity was 0.12%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com