Low-noise and large-power hydraulic plunger pump

A hydraulic plunger pump, high-power technology, applied in the field of hydraulic plunger pumps, can solve the problems of poor adaptability and poor adaptability, and achieve the effects of good sealing performance, increased rated working pressure, and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

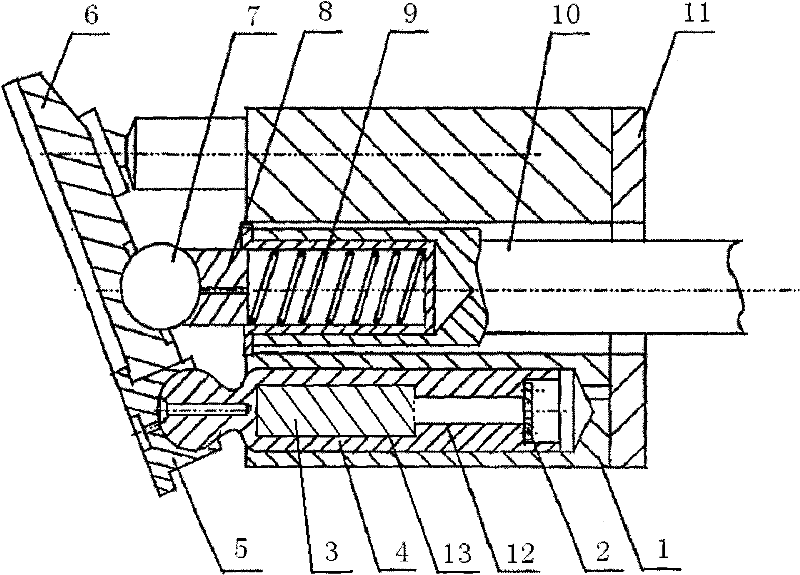

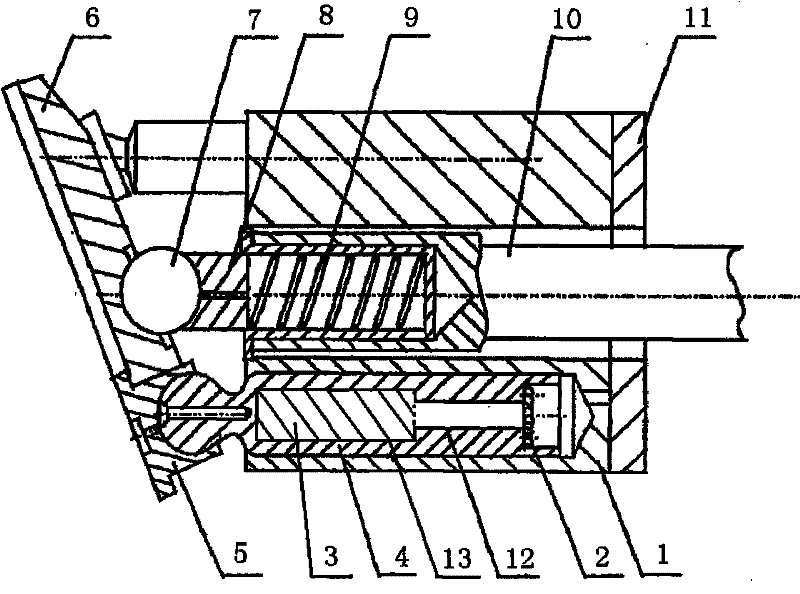

[0010] See eg figure 1 , a low-noise high-power hydraulic plunger pump, including a cylinder 1, a flange 2, an accumulator 3, a plunger 4, a shoe 5, a pressure plate 6, a steel ball 7, an inner sleeve 8, a spring 9, and a main shaft 10. Distributing plate 11, the end surface of the inner cavity of the plunger close to the end of the distributing plate is equipped with a flange 2 with several small through holes in the axial direction, and the inner cavity of the plunger 4 facing the side of the distribution device is A small cavity 12, towards the blind end is a large cavity 13, the accumulator 3 is arranged in the large cavity 13 of the inner cavity of the plunger 4, and the accumulator is connected with the internal cavity of the plunger 4 The large cavity 13 of the cavity is of the same shape as an infused elastic material or a viscoelastic damping material. The accumulator is arranged in the large cavity of the inner cavity of the plunger. The inner cavity of the plunger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com