Novel high-brightness entire-light-emitting LED (Light Emitting Diode) illuminating lamp tube

A technology of LED lighting and whole body lighting, applied in lighting devices, lighting and heating equipment, components of lighting devices, etc., can solve the problems of uneven lighting, reduced LED service life, poor heat dissipation, etc. Brightness output, the effect of reducing light loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

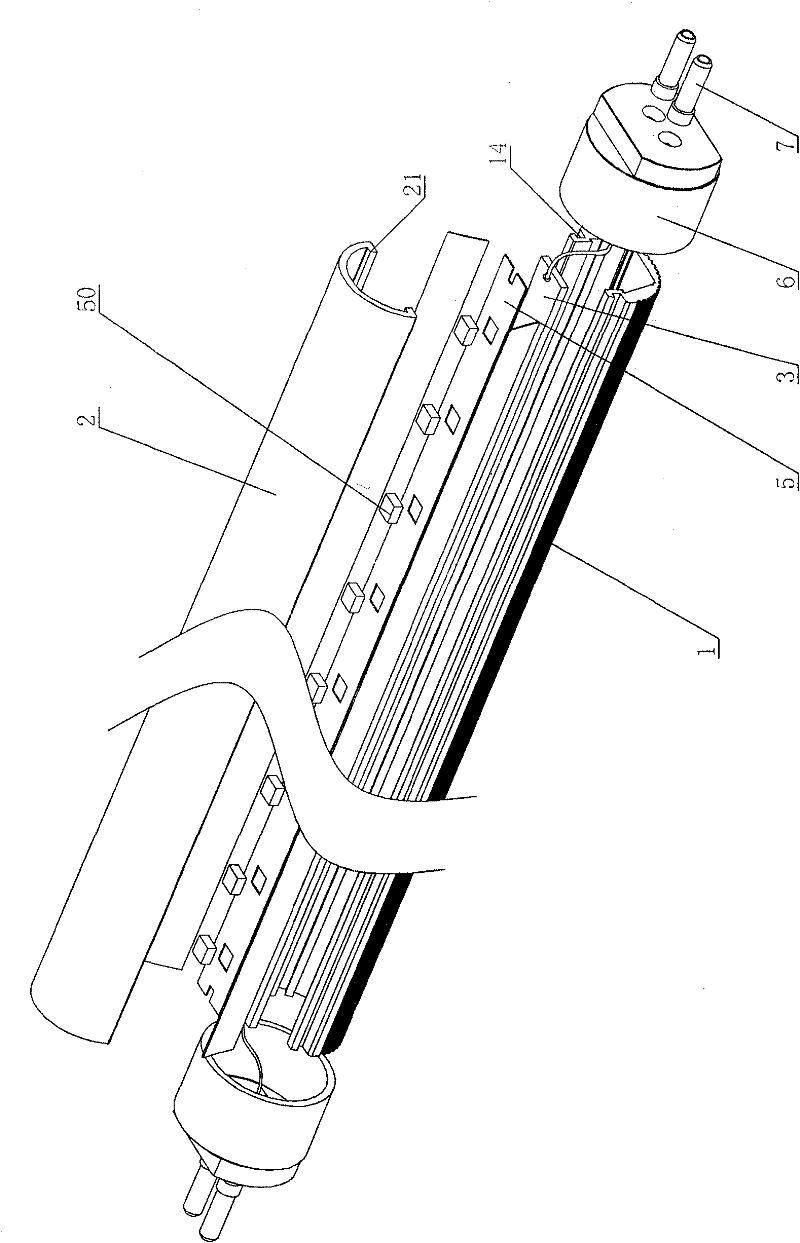

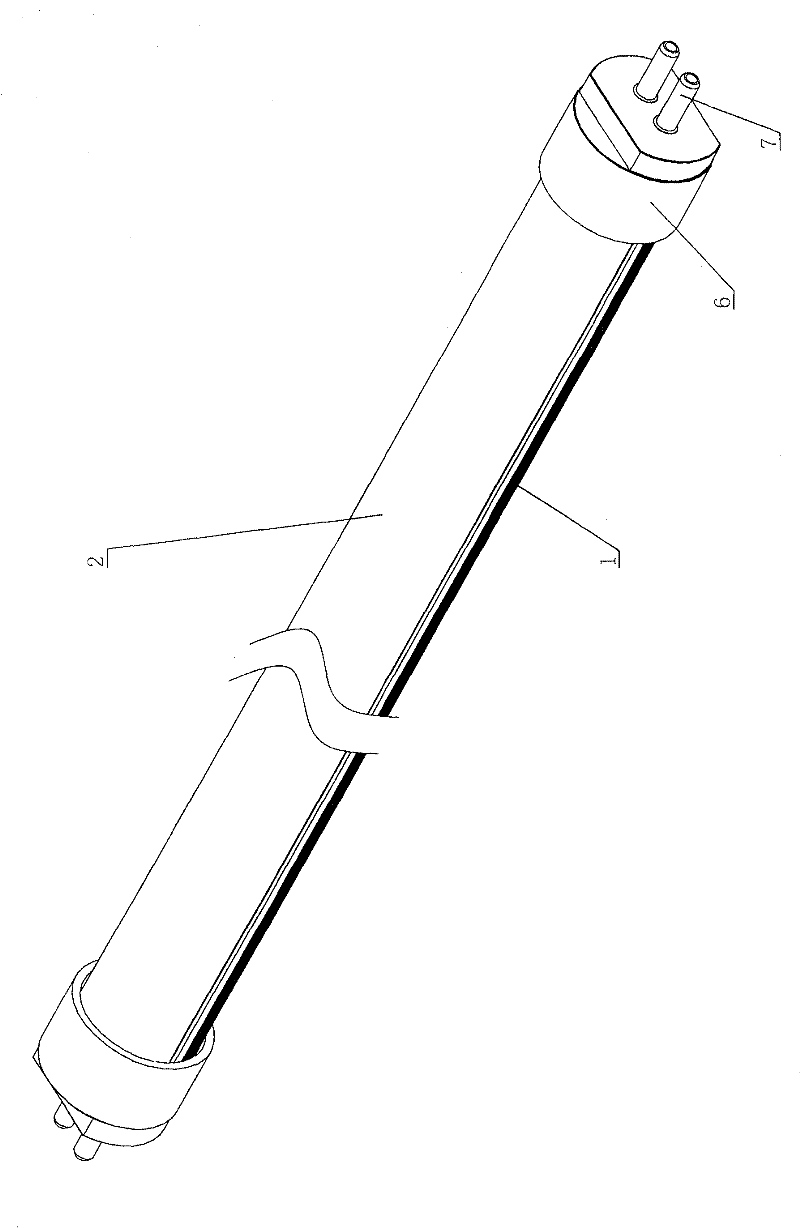

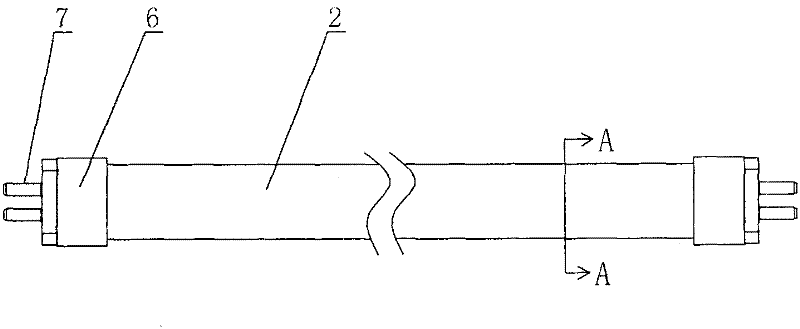

[0019] Such as Figure 1 to Figure 4 The high-brightness full-body luminescent new-type LED lighting tube shown includes a radiator 1, a lens 2, a PCB board 3, a low-thermal-resistance SMD LED 50, reflective paper 5, a plug 6, and pins 7. The radiator 1 and the lens 2 are fastened together to form a hollow tube body, the plugs 6 are installed at both ends of the tube body, and the pins 7 are installed on the plugs. The heat sink includes a body 16 and heat dissipation fins 17 arranged on the outer surface of the body to increase the heat dissipation area and improve the heat dissipation effect.

[0020] Such as figure 1 and Figure 4 As shown, the upper edge of the radiator 1 extends inwardly with a first protrusion 11, and the inner lower edge of the first protrusion 11 extends downward with a second protrusion 12. The lower surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com