Multi-connected sludge specific resistance measurement device

A sludge specific resistance and measurement device technology, which is applied in the direction of soil material testing, material inspection products, etc., can solve the problems of water splashing, inconvenient disassembly and transportation, and no movable integration, so as to achieve flexible and convenient transportation and improve Accuracy, easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

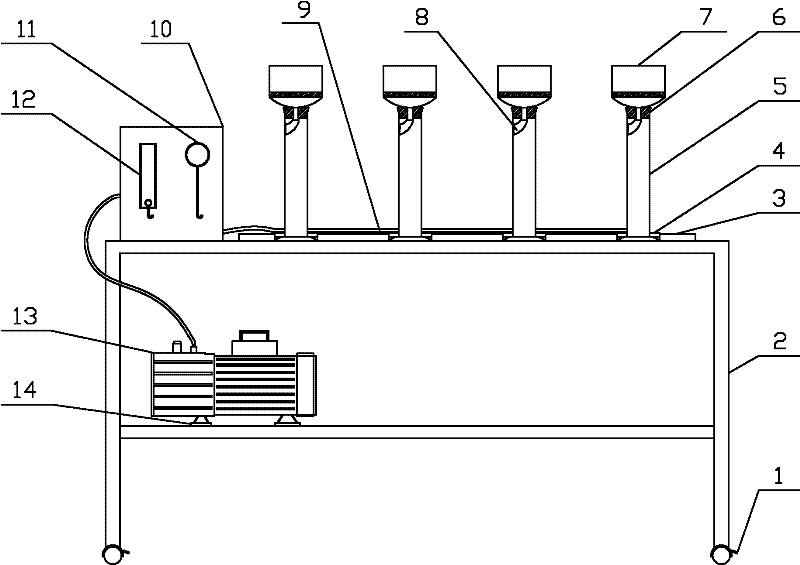

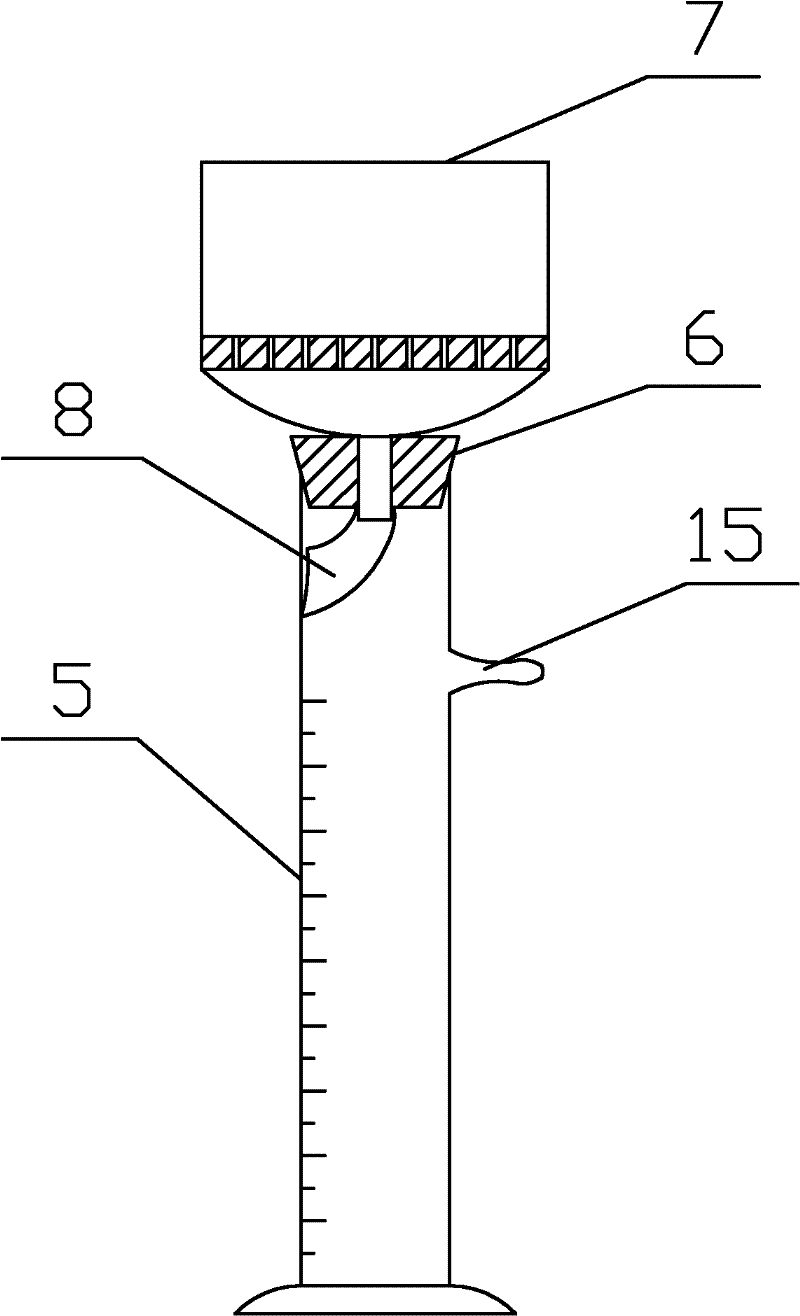

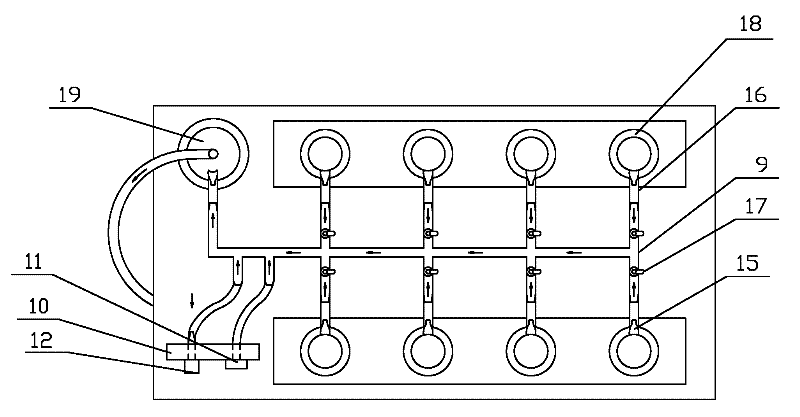

[0024] An eight-packed sludge specific resistance measuring device, figure 1 Schematic diagram of the main view structure, image 3 It is a top view schematic diagram, including an experimental bench 2 with four universal wheels 1 installed at the bottom, a vacuum pump 13 is fixedly installed in the experimental bench 2, a shock absorbing gasket 14 is arranged between the experimental bench 2 and the vacuum pump 13, and the table top of the experimental bench 2 A three-dimensional plate 10 and a copper tree-shaped tube 9 are fixed on the top, and a suction filter bottle 19 is embedded in the table of the test bench 2, and 8 grooves 18 and 8 bases of the measuring cylinder 5 are also arranged on the table of the test bench 2. The easy-to-detachable silicone ring is fixed and embedded in the groove 18, and the mouth of each measuring cylinder 5 is connected with a Buchner funnel 7 through a cork 6, and a protruding suction filter 15 is arranged above the measuring cylinder 5, an...

Embodiment 2

[0027] An automatic control eight-package sludge specific resistance measuring device, figure 1 Schematic diagram of the main view structure, Figure 4 It is a top view schematic diagram, including an experimental bench 2 with four universal wheels 1 installed at the bottom, a vacuum pump 13 is fixedly installed in the experimental bench 2, a shock absorbing gasket 14 is arranged between the experimental bench 2 and the vacuum pump 13, and the table top of the experimental bench 2 A three-dimensional plate 10 and an aluminum tree-shaped tube 9 are fixed on the top, and a suction filter bottle 19 is embedded in the table of the test bench 2, and 8 grooves 18 and 8 bases of the measuring cylinder 5 are also arranged on the table of the test bench 2. It is fixed and embedded in 8 grooves 18 through an easily detachable silicone ring, and the mouth of each measuring cylinder 5 is connected with a Buchner funnel 7 through a cork 6, and a protruding suction filter 15 is arranged abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com