Method for testing sand-suspending performance of foam fracturing fluid used for coal bed gas

A technology of foam fracturing fluid and testing method, which is applied in the direction of material inspection products, instruments, analysis materials, etc., can solve problems such as damage, reservoir permeability drop, etc., and achieve short test time, simple test process, and low test cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

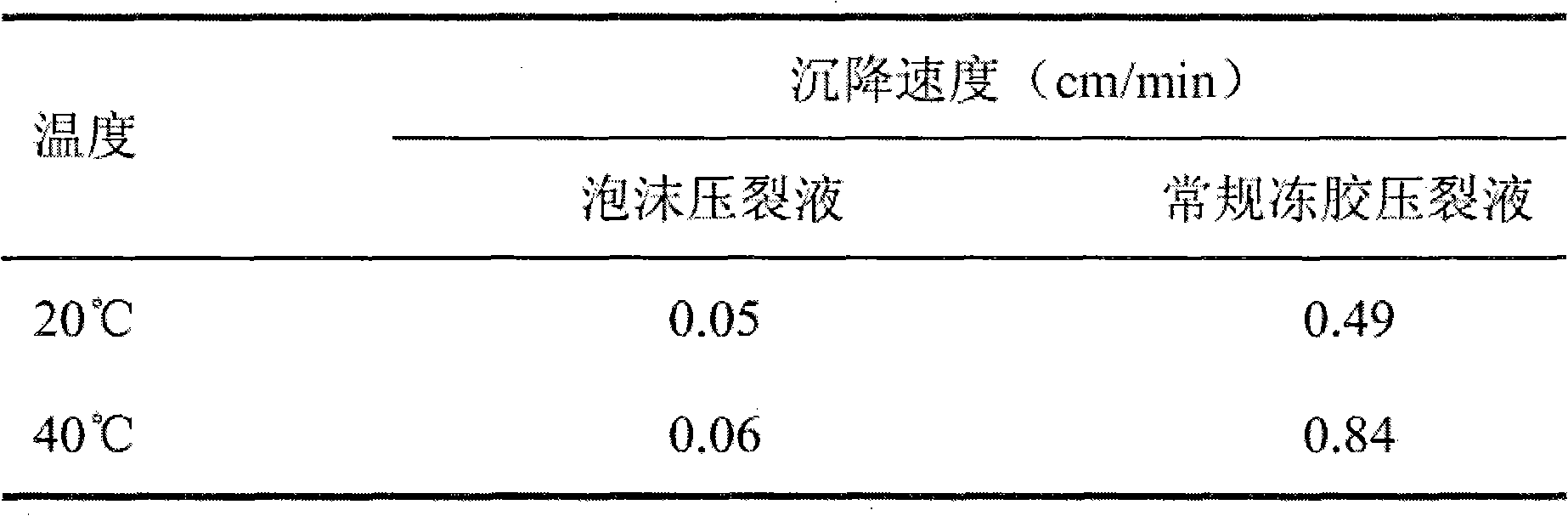

[0045] A method for testing the suspended sand performance of a foam fracturing fluid for coalbed methane that the present invention relates to comprises the following steps:

[0046] (a) preparing foam fracturing fluid;

[0047] (b) Add foam fracturing fluid and conventional jelly fracturing fluid into the graduated cylinder respectively;

[0048] (c) adding ceramsite;

[0049] (d) Place the graduated cylinder in a constant temperature water bath;

[0050] (e) By observing the settling velocity of the ceramsite, analyze the suspended sand performance of the foam fracturing fluid.

[0051] In the step (a), the foam fracturing fluid is 100 grams.

[0052] In the step (a), the foam mass fraction in the foam fracturing fluid is 55%.

[0053] In the step (b), the volume of the measuring cylinder is 500ml.

[0054] In the step (c), ceramsite is added in a ratio of 25% to sand.

[0055] In the step (c), the densities of the ceramsite are different.

[0056] In the step (e), t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com