Pressure control method and device of transmission cavity as well as plasma equipment

A transmission chamber and pressure technology, which is applied in the direction of electric fluid pressure control, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of high cost of pressure control equipment, incapability of real-time and dynamic control of the air pressure in the transmission chamber, etc. Achieve the effect of saving equipment cost, shortening the time of pressure adjustment, and ensuring real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

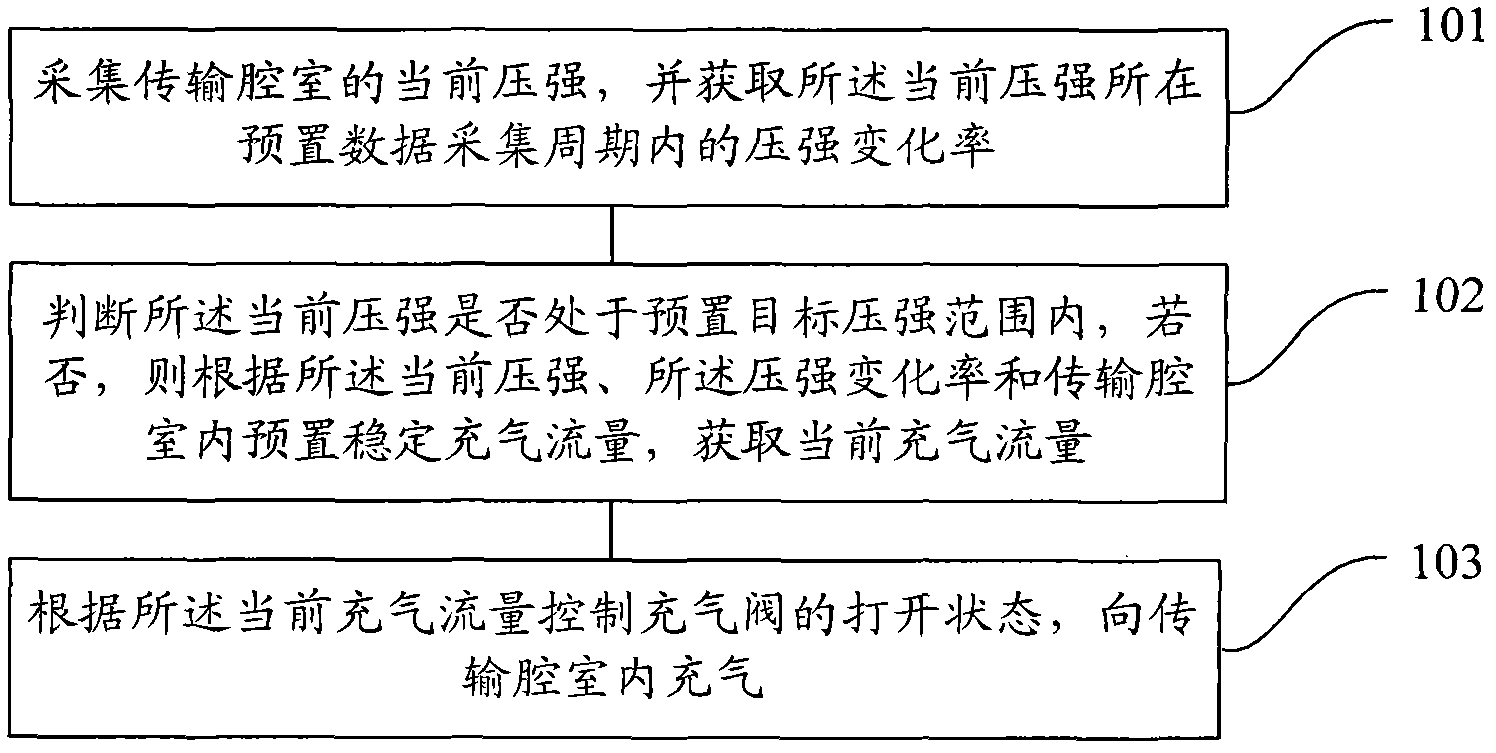

Method used

Image

Examples

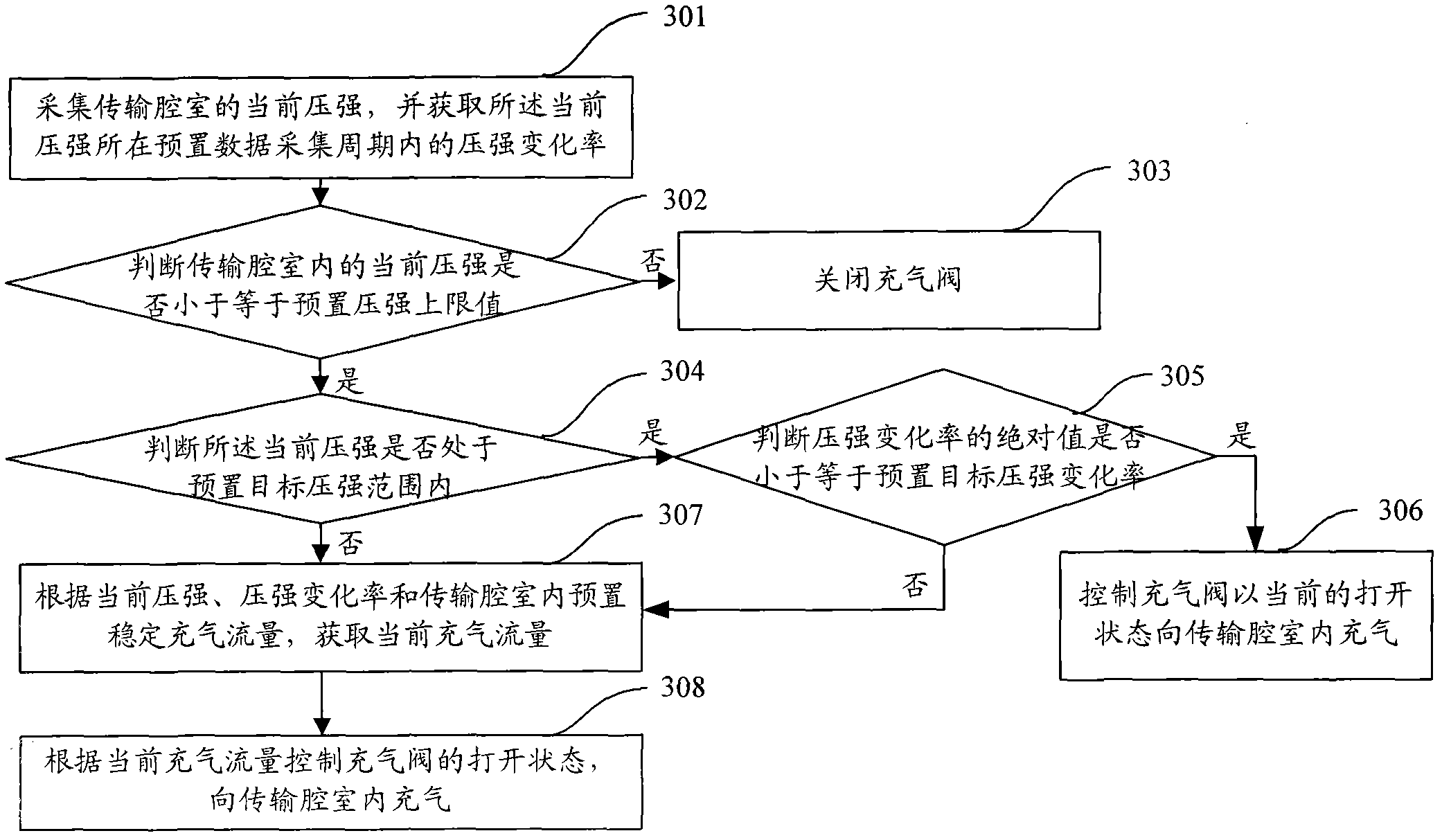

Embodiment 2

[0083] Step 308 in the second embodiment is the same as step 103 in the first embodiment, and will not be repeated here. After step 308 is executed, it is necessary to return to step 301 and execute the above steps in a loop until the end of the pressure control process.

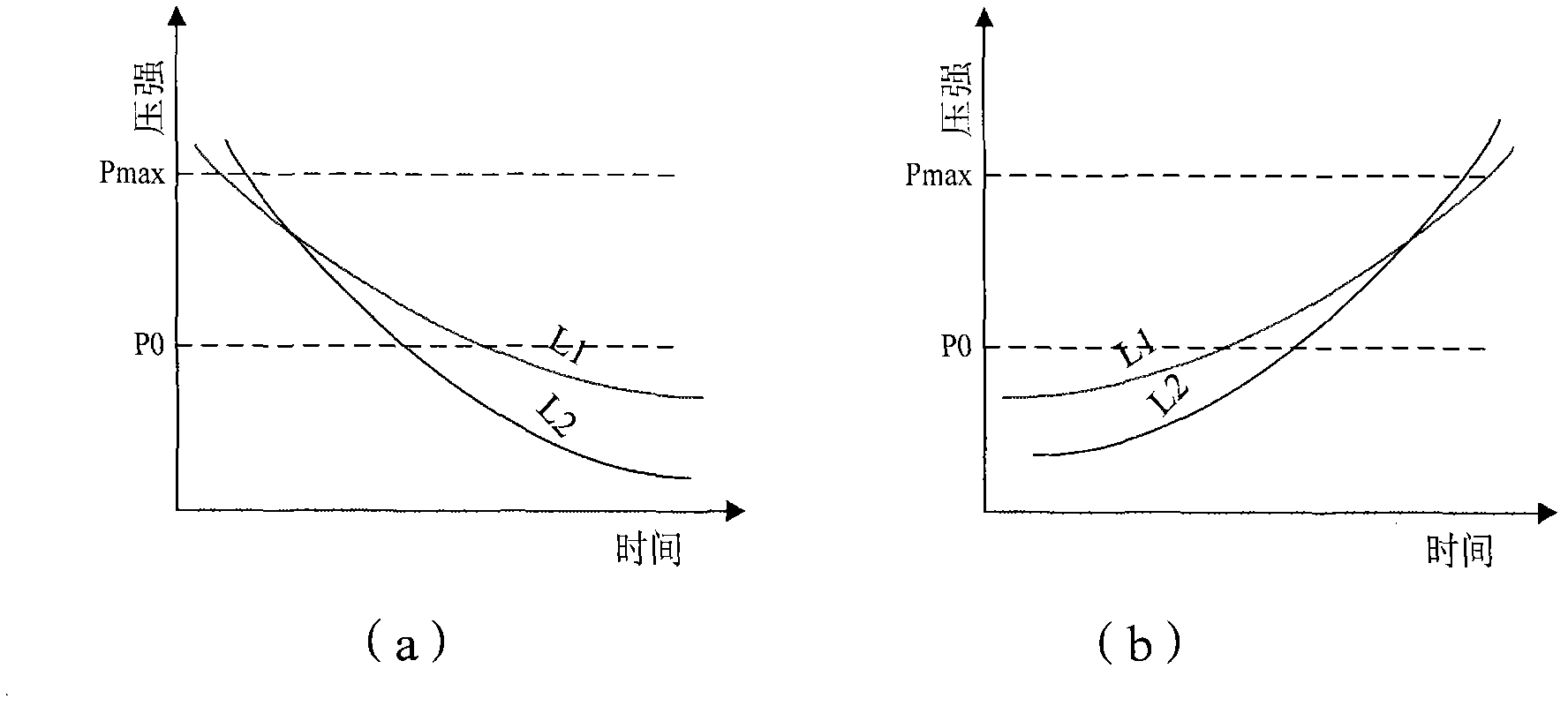

[0084] Compared with Embodiment 1, Embodiment 2 of the present invention, when the current pressure in the transmission chamber is higher than the preset threshold value, by completely closing the inflation valve, the pressure in the transmission chamber can be reduced rapidly, shortening the time for pressure adjustment, and improving the controllability. pressure efficiency. When the current pressure is within the preset target pressure range, and the absolute value of the pressure change rate within the preset data collection period is less than or equal to the preset target pressure change rate, the second embodiment of the present invention does not recalculate and modify the inflation flow rate to prev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com