Forming method for memory device

A technology for storage devices and storage areas, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, circuits, etc., can solve the problems of decreased isolation effect of active devices, and achieve the effects of avoiding the decrease of isolation effect, avoiding pollution, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

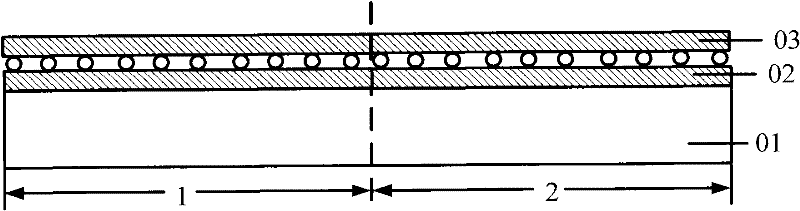

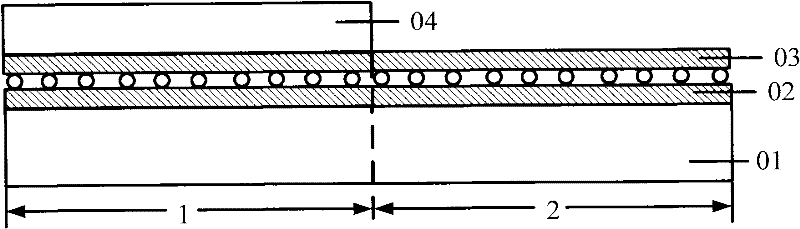

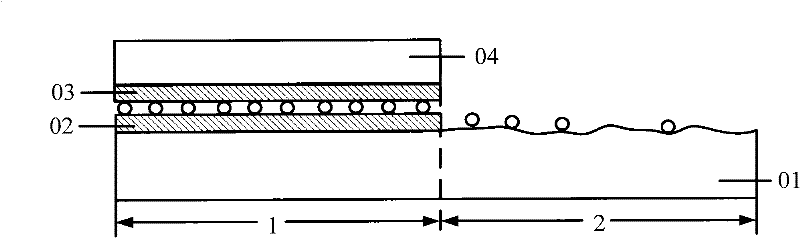

[0029] refer to image 3 , the inventors found that the performance of the circuit in the peripheral region is not stable, and the reasons for the poor isolation effect between the corresponding active devices are as follows: in order to completely remove the nanocrystalline particles, it is necessary to tunnel the tunnels under the nanocrystalline particles Only when the oxide layer 02 is completely removed can the nanocrystalline particles be completely removed, otherwise the nanocrystalline particles will adhere to the tunnel oxide layer 02 and are difficult to remove. At the same time, the thickness of the tunneling oxide layer 02 is small, and its thickness range is approximately 10-30 angstroms, and the tunneling oxide layer 02 is formed by dry thermal growth, with high density and slow removal rate, so it can be completely Removing the tunnel oxide layer 02 under the nanocrystalline particles requires a long removal time, and a long etching time will lead to over-etchin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com