Photosensitive modified polyimide resin composition and use thereof

一种聚酰亚胺树脂、聚酰亚胺的技术,应用在感光材料加工、光学、光机械设备等方向,能够解决难以保护羟基等问题,达到密合性优异、耐化学药品性优异、保存稳定性良好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

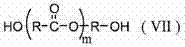

Method used

Image

Examples

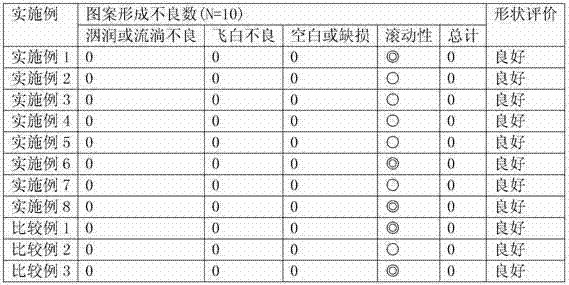

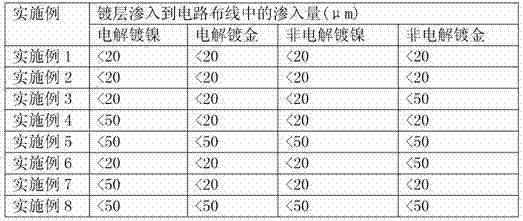

Embodiment 1~8、 comparative example 1~3

[0105] Preparation of positive photosensitive resin composition

[0106] In each of the varnishes (base varnishes) obtained in Synthesis Examples 1 to 2 and Synthesis Comparative Example 1, naphthoquinone diazide sulfonate (manufactured by Daito Chemicals Co., Ltd.) : DTEP-350, PA-6, produced by Toyo Goseisha: 4NT-300), as a flame retardant (large Kagami Corporation: SPB-100, Daihachi Chemical Industry: PX-200, Clarion and Japan: EXOLIT OP 935) were mixed to prepare a photosensitive modified polyimide resin composition (photosensitive ink). Then, about 1 wt% of a leveling agent (manufactured by Cytec Corporation: XL480) was added to the solid content of the polymer, and after final stirring and mixing, defoaming was performed under vacuum to obtain a positive photosensitive modified polyimide resin composition.

[0107] Developability evaluation: photosensitive development test

[0108]Each positive-type photosensitive modified polyimide resin composition obtained in this w...

Embodiment 1~6 and comparative example 1~4

[0113] The following items were evaluated about the photosensitive modified polyimide resin composition shown in said Table 2, and the result is shown in following Table 3.

[0114] Flexibility

[0115] Each flame retardant modified polyimide composition is coated on the substrate by screen printing with a stainless steel plate of 165-3D mesh (mesh), and prebaked by a hot air oven (90 ° C × 30 minutes) to remove the composition The solvent in the solution was used to obtain a photoresist film with a thickness of 14-17 μm. The coating film compounded with photoresist was developed with a developer at 40°C for 2 minutes, washed with deionized water, dried in a hot air oven at 120°C for 60 minutes, and then dried at 180°C for 30 minutes. The thickness of the obtained polyimide film was about 15 μm. About the obtained polyimide film, the coated surface was bent 180 degrees outside, and the presence or absence of a crack in a dried film was visually judged. Judgment criteria are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com