Waterproof mortar material and preparation method thereof

A waterproof mortar and fine sand technology, which is applied in the field of waterproof materials, can solve the problems of unsatisfactory and easy aging, and achieve the effect of convenient operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

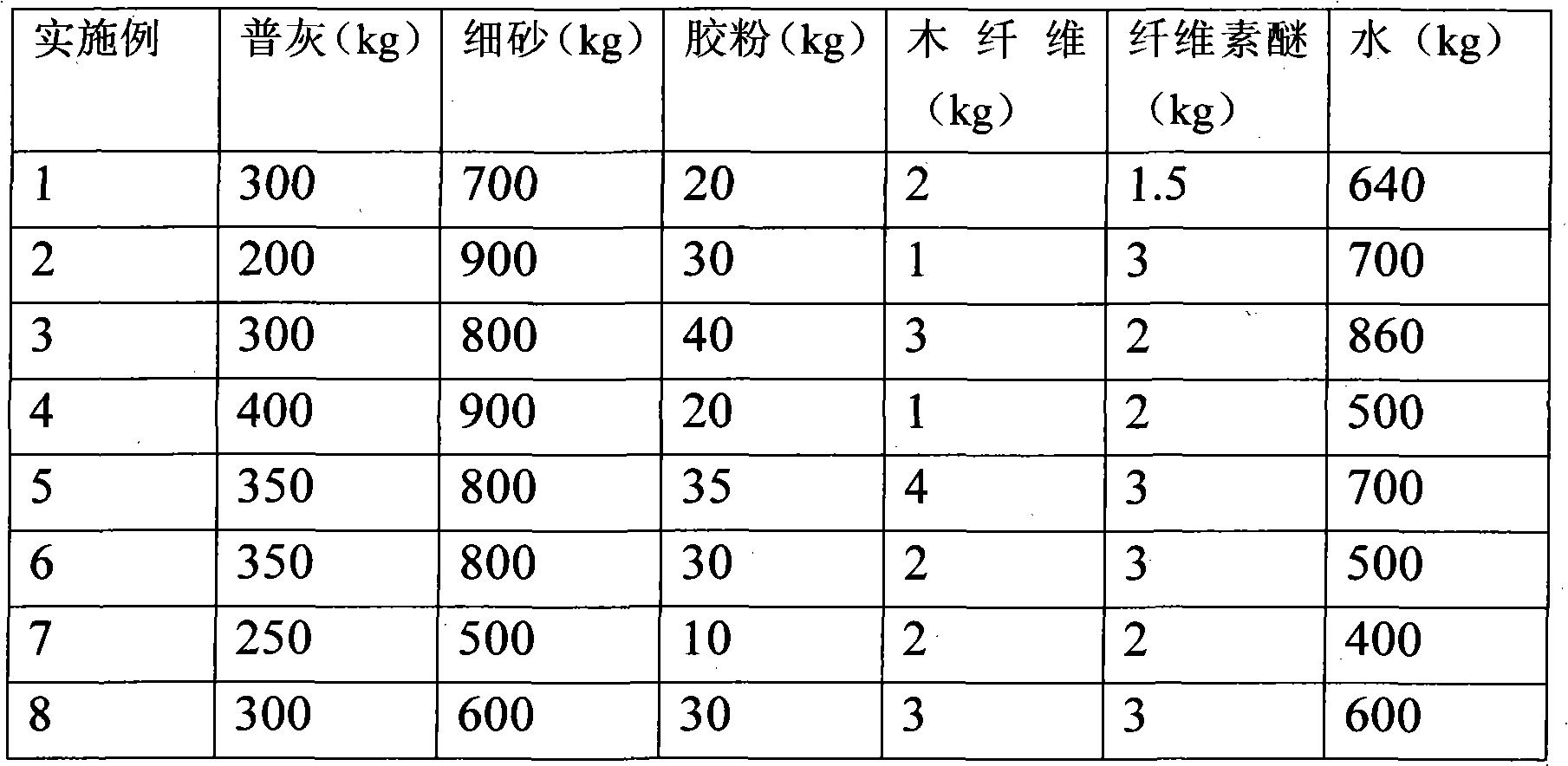

[0016] In the embodiments of the present invention, the weight of each portion is selected to be 1 kg, and each component is made of commonly used materials in the field of construction engineering. The formulas of the specific embodiments are shown in the table below.

[0017]

[0018] The above-mentioned examples were prepared using the following method steps: (1) add common ash, fine sand, rubber powder, wood fiber, and cellulose ether into the container in sequence, and stir at the same time, so that the entire system is finally mixed evenly; (2) Add water to the homogeneously mixed system prepared in step (1), and stir at the same time to make the homogeneously mixed system. The fine sand used is preferably 50-100 mesh.

[0019] The above-mentioned examples were tested for waterproof performance, and the results showed that the waterproof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com