Novel finishing process of co-polymerization fluorine antifouling and soil-releasing finishing liquor

A kind of easy decontamination finishing and copolymerization technology, which can be used in the removal of liquid/gas/vapor, fiber treatment, textile material treatment, etc. It can solve the problems of high investment cost and energy consumption, and achieve the effect of reducing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Fabric: 32S cotton jersey jersey (dyed finished product)

[0030] 2. Finishing liquid formula and process

[0031] Fluorine antifouling and easy decontamination finishing agent: OLEOPHOBOL ZSR (Huntsman) 40g / l

[0032] Fluorine enhancer: fluorine enhancer LK-30 10g / l

[0033] Anti-gelling agent: Triethylhexylphosphoric acid 15g / l

[0034] Supporting softener: Weak cationic softener 3305 20g / l

[0035] Process flow: padding (one dipping and one rolling, the excess rate is 75%)→hot air drying (105°C)→high temperature setting (165°C, 60 seconds)→test index→washing→test index.

[0036] Process conditions: the pH of the dyed cloth to be finished is controlled at 6, and the pH of the padding finishing solution is adjusted at 5. One dipping and one rolling, the excess rate is 75%, the drying temperature is 105°C, the setting temperature is 165°C, the setting time is 60 seconds, the speed is 18m / min, and the overfeed is 12%.

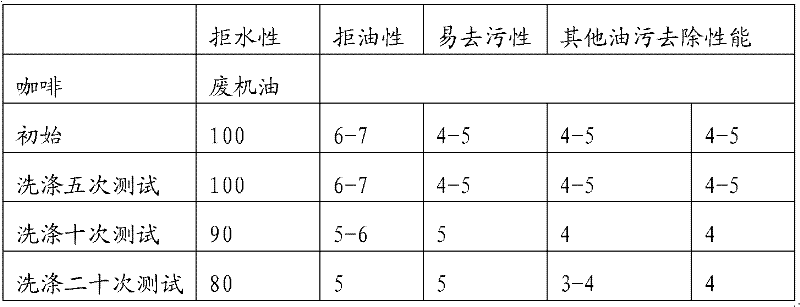

[0037] 3. Test indicators:

[0038] (1) Wa...

Embodiment 2

[0051] 1. Fabric: 32S cotton jersey jersey (dyed finished product)

[0052] 2. Finishing liquid formula and process

[0053] Fluorine antifouling and easy decontamination finishing agent: Baygard (LANXESS) 30g / l

[0054] Fluorine enhancer: Fluorine enhancer LK-30 12g / l

[0055] Anti-gelling agent: polyacrylamide 18g / l

[0056] Supporting softener: modified amino silicone softener LS06 26g / l

[0057] Process flow: padding (one dipping and one rolling, the excess rate is 75%)→hot air drying (85°C)→high temperature setting (170°C, 80 seconds)→test index→washing→test index.

[0058]Process conditions: the pH of the dyed cloth to be finished is controlled at 5, and the pH of the padding finishing solution is adjusted at 7. One dipping and one rolling, the excess rolling rate is 75%, the drying temperature is 85°C, the setting temperature is 170°C, the setting time is 80 seconds, the speed is 18m / min, and the overfeed is 12%.

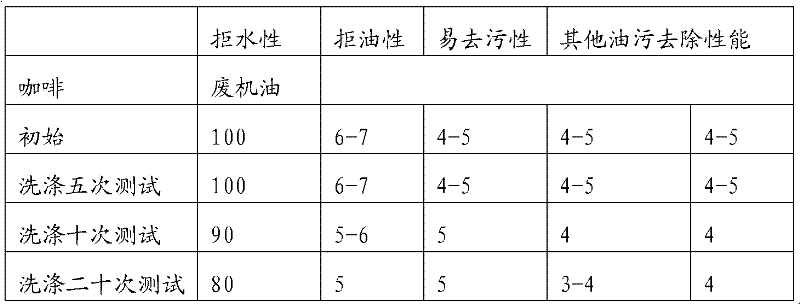

[0059] 3. Test indicators:

[0060] (1) Water rep...

Embodiment 3

[0073] 1. Fabric: 32S cotton jersey jersey (dyed finished product)

[0074] 2. Finishing liquid formula and process

[0075] Fluorine antifouling and easy decontamination finishing agent: UNIDYNE TG-991 (Daikin, Japan) 42g / l

[0076] Fluorine enhancer: Fluorine enhancer LK-30 15g / l

[0077] Anti-gelling agent:

[0078] Sodium lauryl sulfate and polyacrylamide mixture 16g / l

[0079] Supporting softener:

[0080] Modified amino silicone softener LS06 and polyether amino silicone oil softener CGF

[0081] 30g / l

[0082] Process flow: padding (one dipping and one rolling, the excess rate is 75%)→hot air drying (110°C)→high temperature setting (160°C, 65 seconds)→test index→washing→test index.

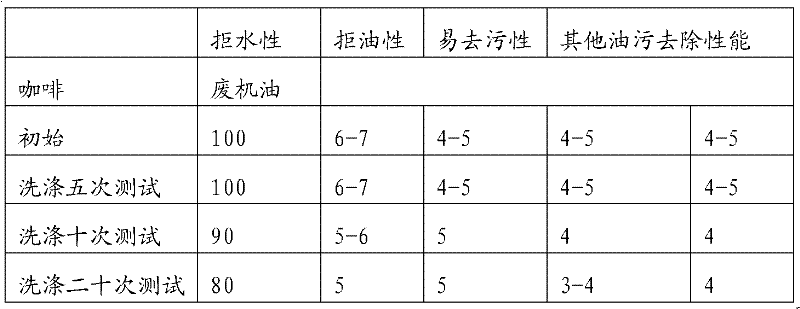

[0083] Process conditions: the pH of the dyed cloth to be finished is controlled at 7, and the pH of the padding finishing solution is adjusted at 5. One dipping and one rolling, the excess rate is 75%, the drying temperature is 110°C, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com