Corrosion-resistant rotary displacement adjuster for pipelines

A displacement regulator and corrosion-resistant technology, applied in pipeline anticorrosion/rust protection, pipeline protection, adjustable connection, etc., can solve the problems of restricted flow of fluid media, increased pressure loss, and inaccurate axial centering, etc. Achieve the effect of unrestricted medium flow, eliminate direct impact, and have no pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

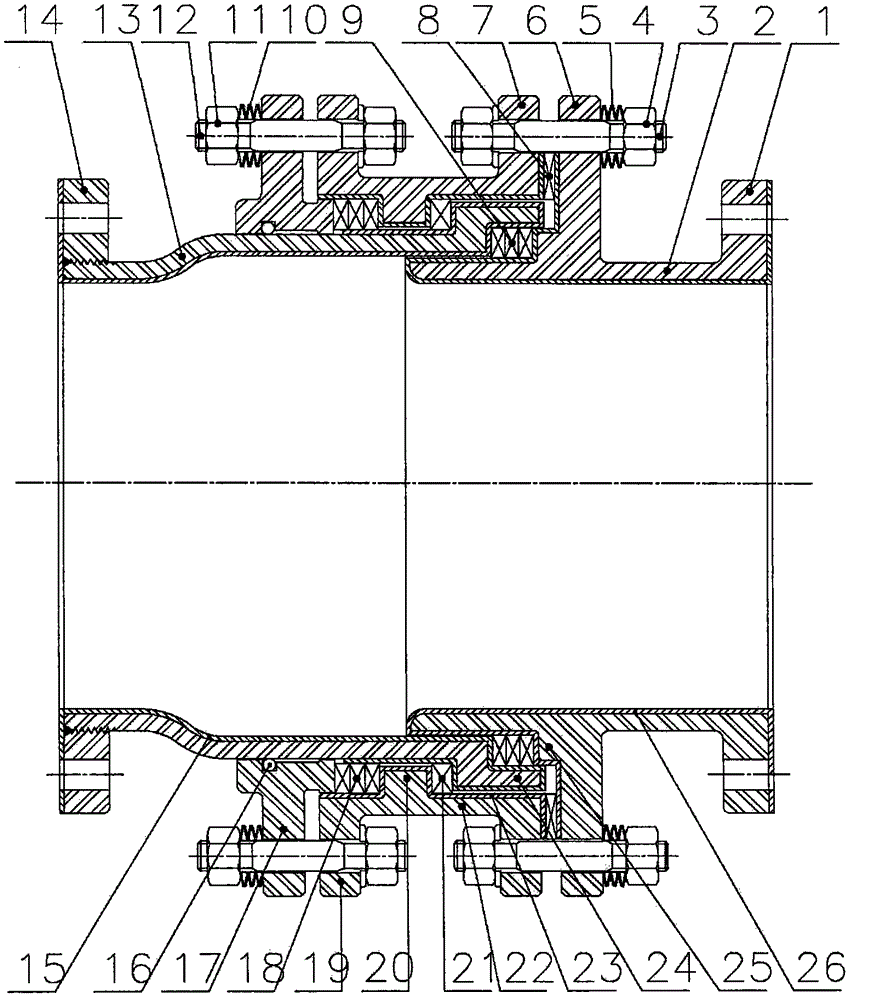

[0061] The technical solutions of the present invention are described in detail below in conjunction with the accompanying drawings.

[0062] Such as figure 1As shown, a corrosion-resistant rotary displacement regulator for pipelines, including external connection flange A1, inner tube 2, bolt A3, nut A4, spring A5, inner tube structure flange 6, outer tube method A7, seal B8 , seal A9, spring B10, nut B11, bolt B12, reducing core tube 13, external connection flange B14, corrosion-resistant cladding layer A15, steel ball 16, pressure piece casing flange 17, seal D18, jacket Pipe flange B19, outer casing inner cap 20, seal C21, outer casing 22, corrosion-resistant coating B23, variable-diameter core tube convex outer ring 24, inner pipe pressure piece cap 25, and corrosion-resistant coating C26 ,in:

[0063] The reduced-diameter core tube 13 is a tube structure with a stepped wide mouth as a whole. The so-called stepped wide-mouth is that the reduced-diameter core tube 13 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com