Fuel nozzle, combustion chamber and gas turbine engine

A technology of fuel nozzle and fuel oil, which is applied in the field of combustion chamber, gas turbine engine and fuel nozzle, which can solve the problems of convective heat transfer of purge gas which is difficult to limit heat, reduce the heating effect of oil circuit, etc., so as to reduce the risk of fuel coking, Eliminates the effects of direct impact and avoids fuel coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

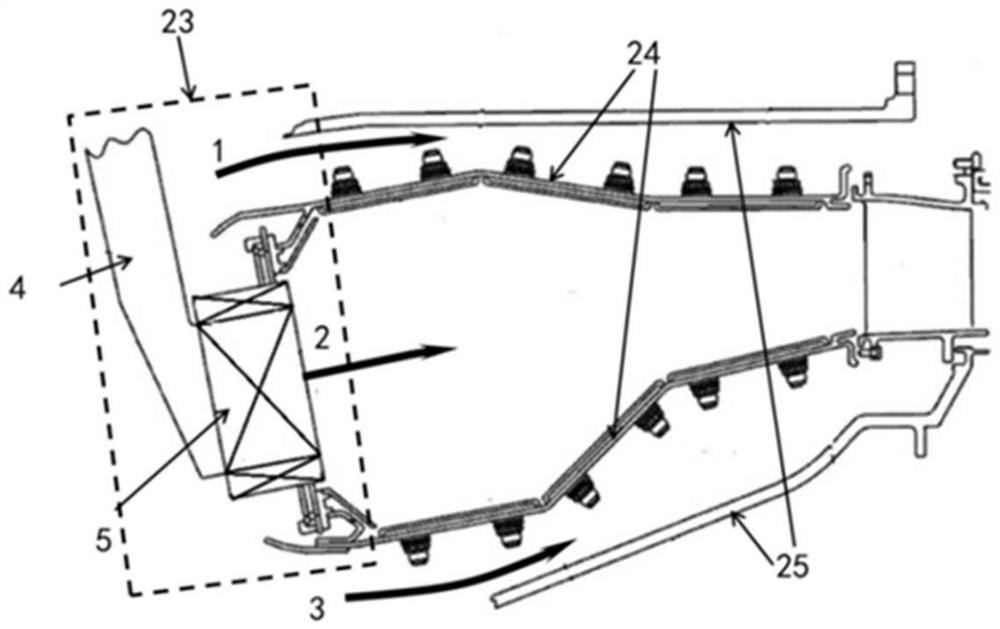

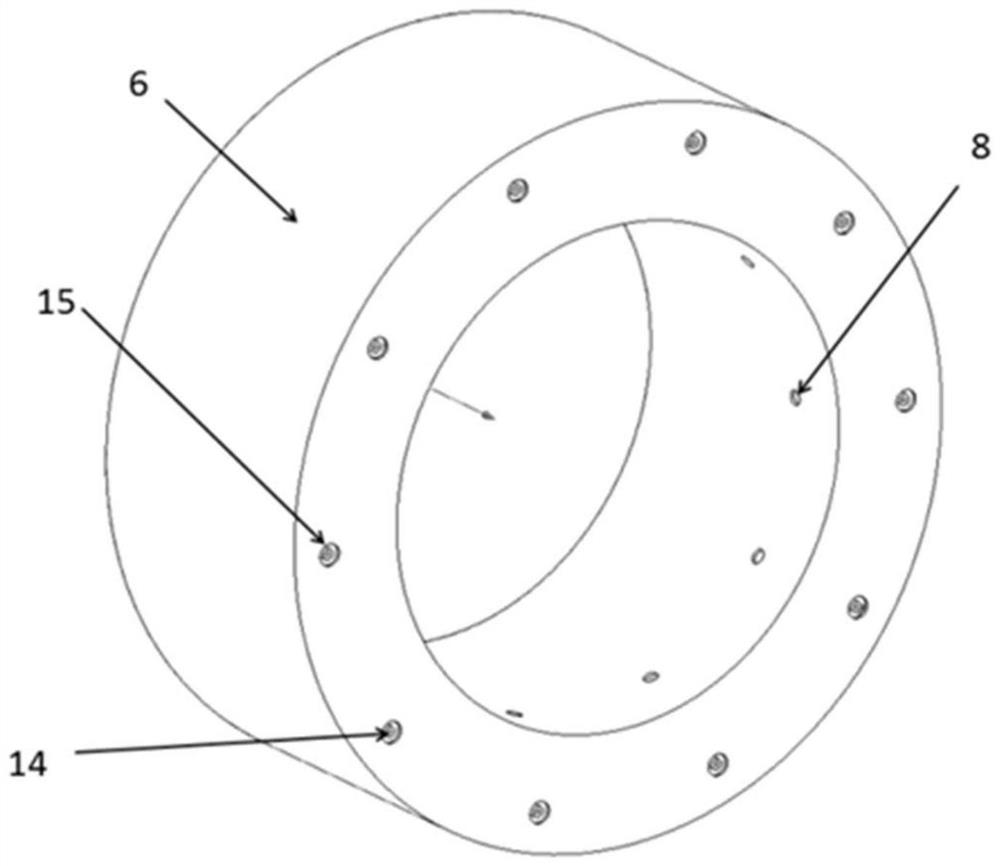

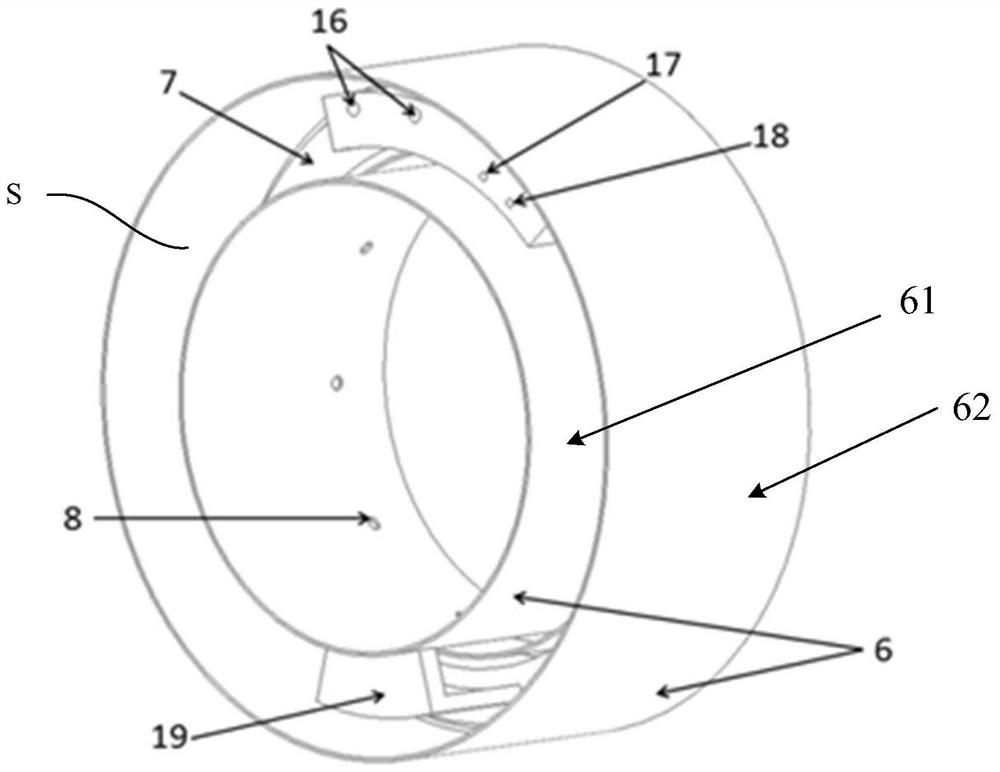

[0047] like Figure 2 to Figure 6 As shown, the fuel nozzle 23 includes a rod core 4 , an oil collecting ring 5 and a nozzle housing 6 , and the nozzle housing 6 provides an accommodating space S for accommodating the oil collecting ring 5 in the accommodating space S. The specific structure of the nozzle housing 6 may include a radial inner wall 61 and a radial outer wall 62, the radial gap between the radial inner wall 61 and the radial outer wall 62 defines the accommodation space S, and the radial inner wall 61 has a circumferential distribution. The air hole 8 is formed, so that the hot air flow enters the accommodating space from the air hole 8, so as to realize the differential pressure purging of the residual fuel when the fuel nozzle stops running.

[0048] The oil collecting ring 5 has an oil collecting ring body 7 and an oil passage 100 located inside the oil collecting ring body 7, for example Figure 4A as well as Figure 4B The shown can include the main oil ci...

no. 2 example

[0052] The parts of the second embodiment that are the same as those of the first embodiment will not be described in detail here.

[0053] refer to Figure 7A , Figure 7B as well as Figure 8 As shown, the heat insulation cavity of the second embodiment is a semi-closed heat insulation cavity 13 with one end closed and one end open. , demand and other factors to change the shape and protection area of the thermal insulation cavity), and avoid the position where the fuel nozzle 14 protrudes. The difference between the semi-closed thermal insulation cavity 13 and the thermal insulation cavity 12 is that the air in the semi-closed thermal insulation cavity 13 communicates with the outside of the thermal insulation cavity. The air flow in the cavity 13 is slow, and the thermal protection effect equivalent to that of the closed thermal insulation cavity 12 can be achieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com