Method for manufacturing photon sieve with high height-width ratio

A technology of photon sieve and aspect ratio, which is applied in the field of making photon sieves with large aspect ratios, can solve problems such as being easy to fall and difficult to manufacture photonic sieves with high aspect ratios, and achieves high success rate, reduced production costs, and wide application The effect of applying the foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

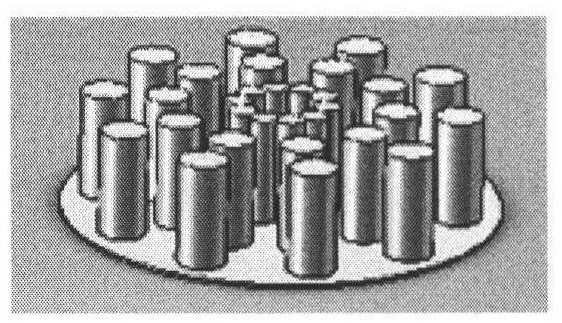

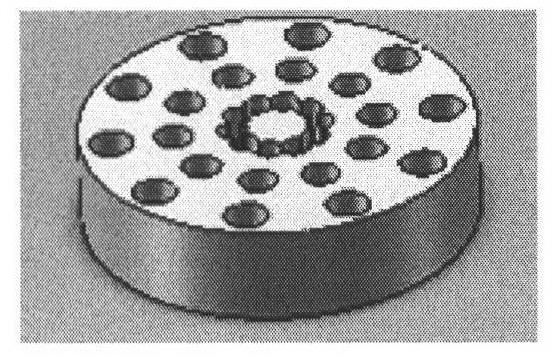

[0038] The method for making a photon sieve with a large aspect ratio provided by the present invention is mainly realized based on Babinet's principle. The Babinet principle means: under the illumination of a point light source, two complementary diffraction screens u0(x, y), uc(x, y) are on the plane conjugate to the point light source, except for the geometric image point of the point light source , both have the same Fraunhofer diffraction pattern. It can be seen from Babinet's principle that although the physical structure of the photon sieve produced by the present invention is different from that of the traditional one, it still does not affect the performance of the photon sieve as a whole.

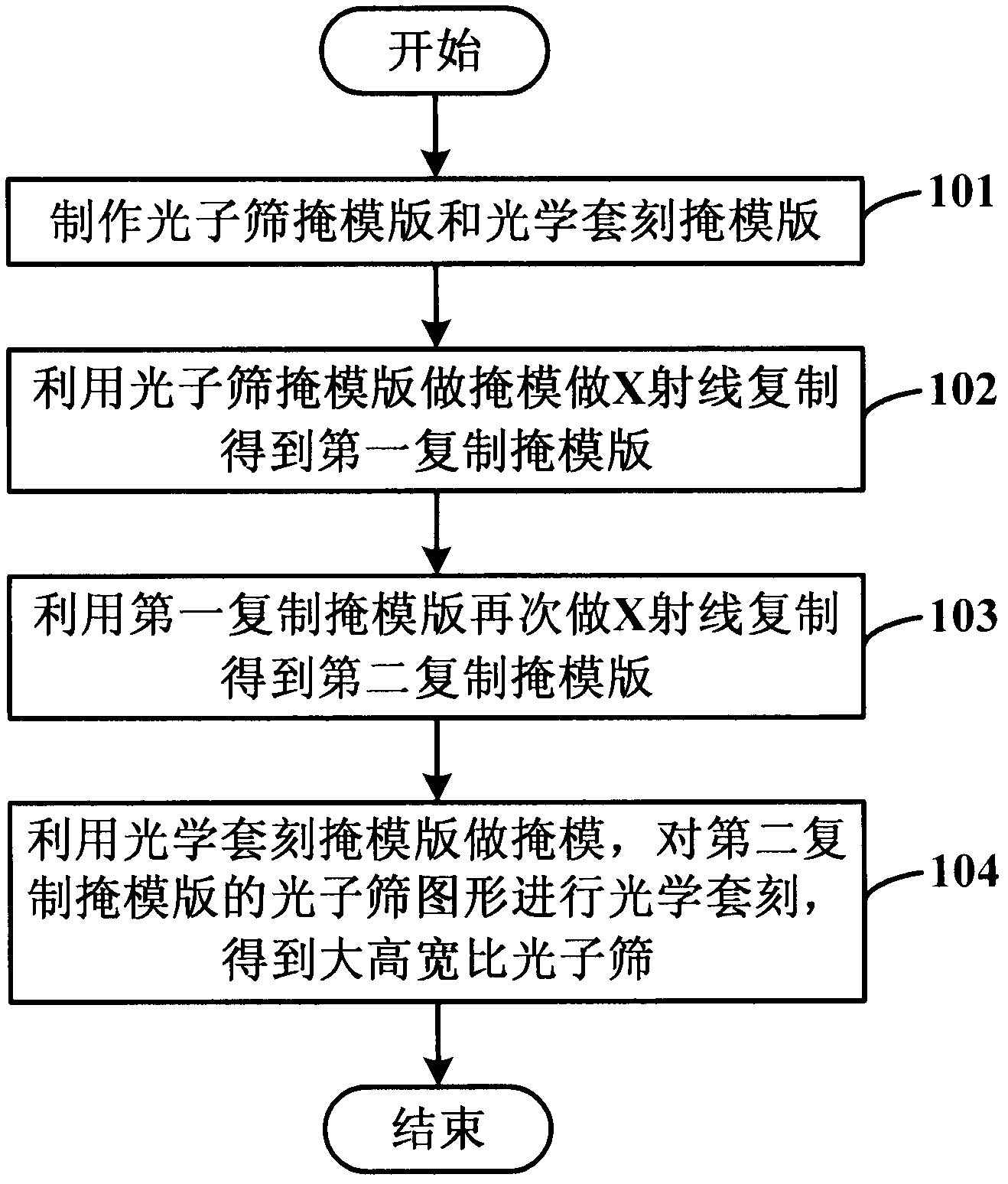

[0039] Such as figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com