Interference microscope and measuring apparatus

An interference microscope and interference fringe technology, applied in microscopes, measuring devices, interferometers, etc., can solve the problems of complex structures and inability to miniaturize devices, and achieve the effects of simple structures and improved work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

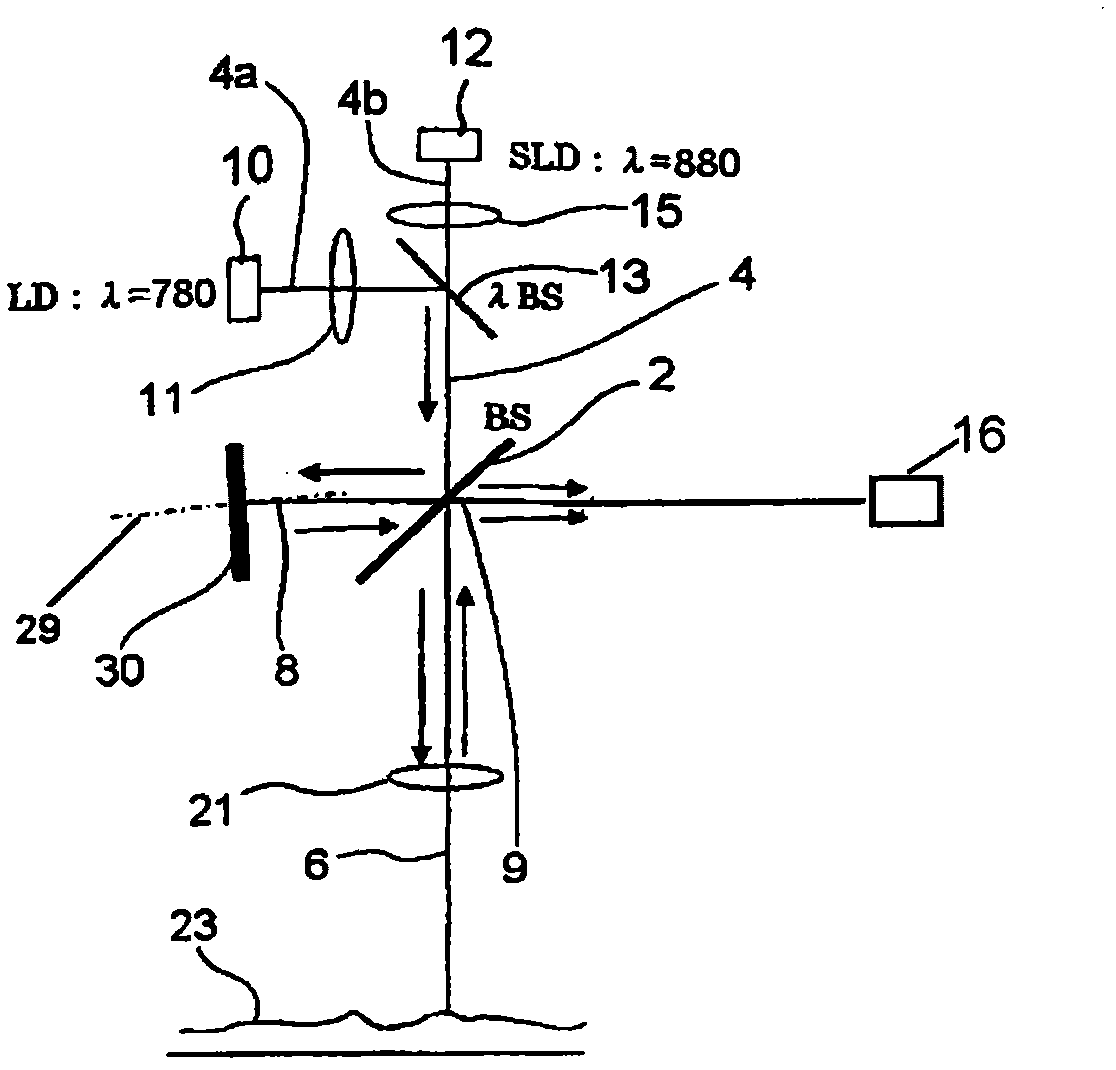

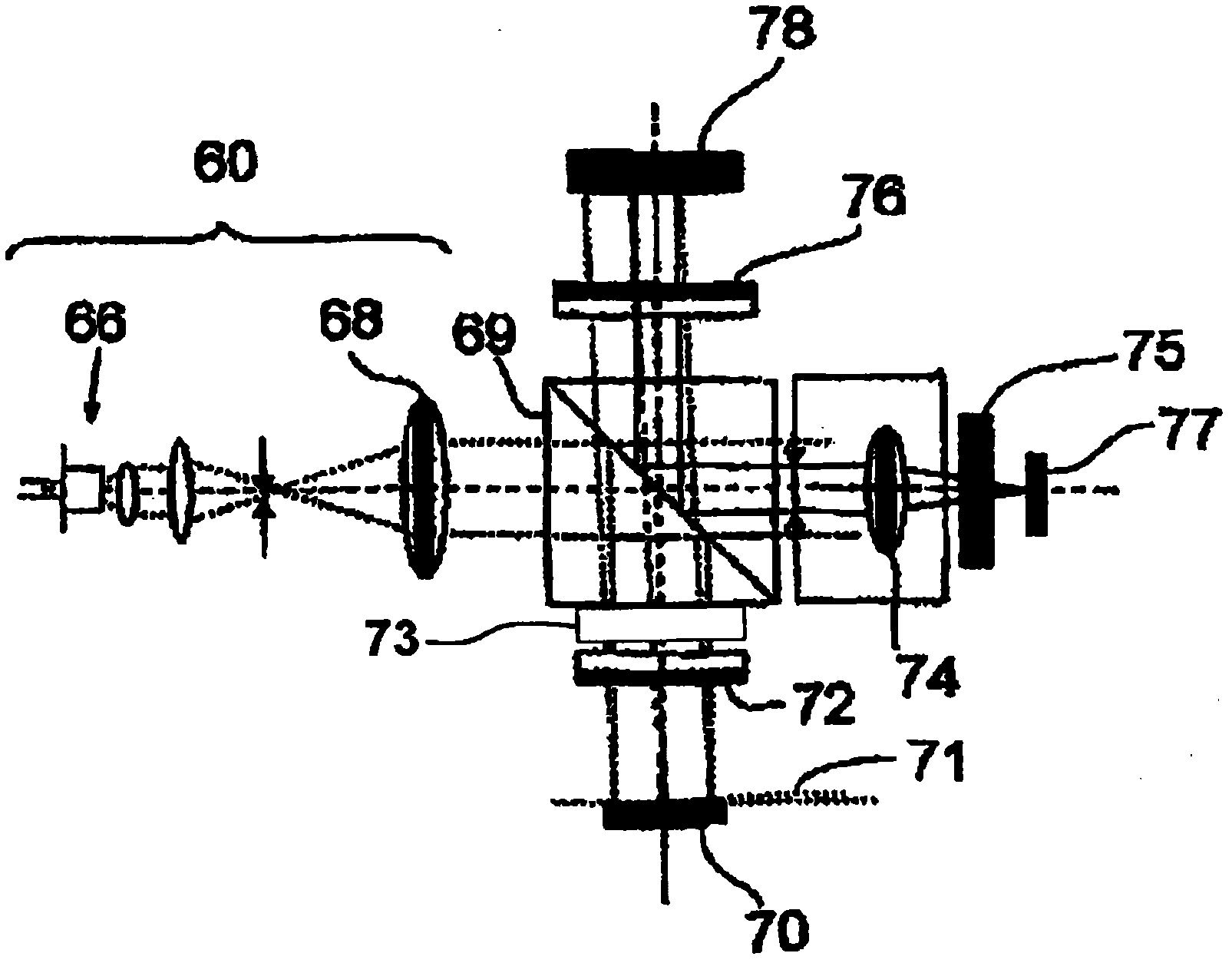

[0049] The interference microscope and measurement device of the present invention use various interferometers.

[0050] In a preferred embodiment of the invention, a Michelson interferometer is used. However, a Linick (phase shift type) interferometer may also be used as long as the effect of the present invention can be achieved.

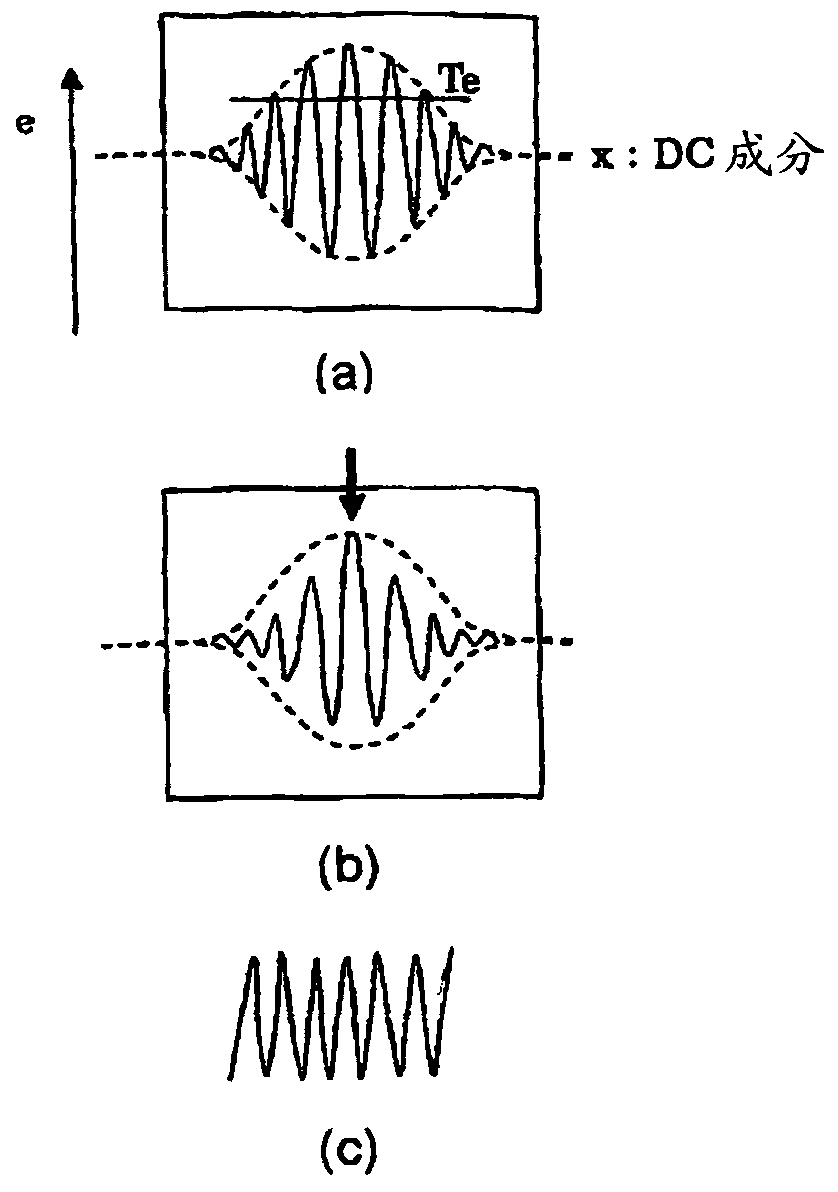

[0051] For reference, it is conceivable to use an interferometer of time domain refractometry as an interferometer, and to perform a micro-oscillation (micro-momentum Δλ) of the reference mirror (Ref) as shown below, for example.

[0052] λ=800nm

[0053] Δλ=30nm

[0054] Resolution: ΔZ=21m / π·λ 2 / Δλ

[0055] =9.4μ

[0056] Horizontal resolution: ΔX=4λ / π f / d

[0057] The scanning area in the direction of the optical axis is 2Z o =ΔX 2 π / 2λ.

[0058] However, in this case, the resolution is limited, and it is not easy to inspect the shape of ultrafine regions such as dust and pole pieces on the object to be measured (sample) suc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com