Metamaterial substrate and preparation method thereof

A technology of metamaterials and substrates, applied in the field of metamaterials, can solve the problems of high loss and high dielectric constant of PCB substrates, and achieve the effects of light weight, low dielectric constant and loss, and wide application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A method for preparing a metamaterial substrate, the method for preparing comprises the following steps:

[0024] a. Mix the microsphere foaming agent and thermoplastic polymer melt, stir to form a uniform mixing system, and then vacuum defoam for 5-10 minutes;

[0025] Specifically, the thermoplastic polymer is any one of polyethylene, polypropylene, polystyrene or polyvinyl chloride;

[0026] b. Heat the mixed system to the foaming temperature of the microsphere foaming agent to allow the microspheres to fully expand;

[0027] Specifically, the content of the hollow microspheres in the prepared substrate is controlled by controlling the ratio of the microsphere foaming agent, and the ratio of the microsphere foaming agent is adjusted according to the required dielectric constant of the substrate in practical applications. The greater the addition ratio of the foaming agent, the smaller the dielectric constant of the substrate; at the same time, the pore size of the h...

Embodiment 1

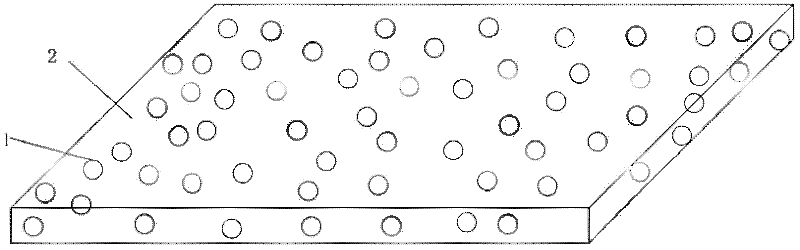

[0032] Embodiment one: if figure 1 as shown,

[0033] a. Mix the microsphere foaming agent and polyethylene melt, stir to form a uniform mixing system, and then vacuum defoam for 5 minutes. The shell of the microsphere foaming agent is a thermoplastic acrylic resin polymer, and the inner core is composed of alkane gas Spherical plastic particles, generally 20 microns in diameter;

[0034] b. Heat the mixed system to the foaming temperature of the microsphere foaming agent at 150°C, let the microspheres fully expand, the alkane gas in the shell expands, and the volume of the foaming agent can rapidly expand to 25 times its own;

[0035] c. Inject the fully foamed mixed system into a prefabricated mold, then cool and demould, and prepare a metamaterial substrate containing hollow microspheres.

[0036] A metamaterial substrate containing hollow microspheres is prepared by using a microsphere foaming agent, and the density and dielectric constant of the substrate are reduced by...

Embodiment 2

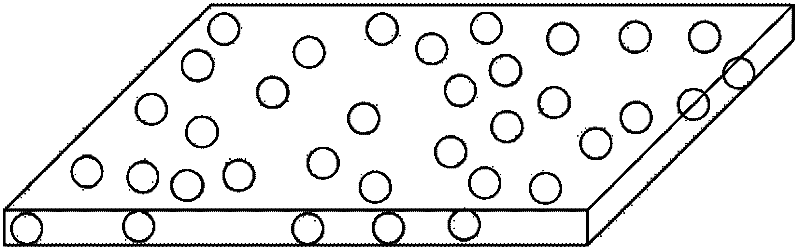

[0037] Embodiment two: if figure 2 as shown,

[0038] The difference between the second embodiment and the first embodiment is that the alkane gas spherical plastic particles in the inner core are different, and the alkane gas particles with a larger expansion rate than the first embodiment are used, and the volume of the foaming agent can expand to its own volume. 30-70 times, the preparation is relative to the metamaterial substrate with a lower dielectric constant than that of Example 1, using different alkane gas particles, and the expansion ratio of the microsphere foaming agent is different, so that the dielectric constant of the metamaterial substrate prepared Also different; the greater the expansion rate of the microsphere foaming agent, the larger the pore size of the hollow microsphere, and the smaller the dielectric constant.

[0039] It should be understood that the use of a microsphere blowing agent with a larger volume than the alkane gas particles in Example ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com