Resonance hydrogen and oxygen generator

A hydrogen-oxygen machine and voltage technology, applied in the field of hydrogen-oxygen machines, can solve the problems of low oxygen production capacity, slow gas production, high temperature, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

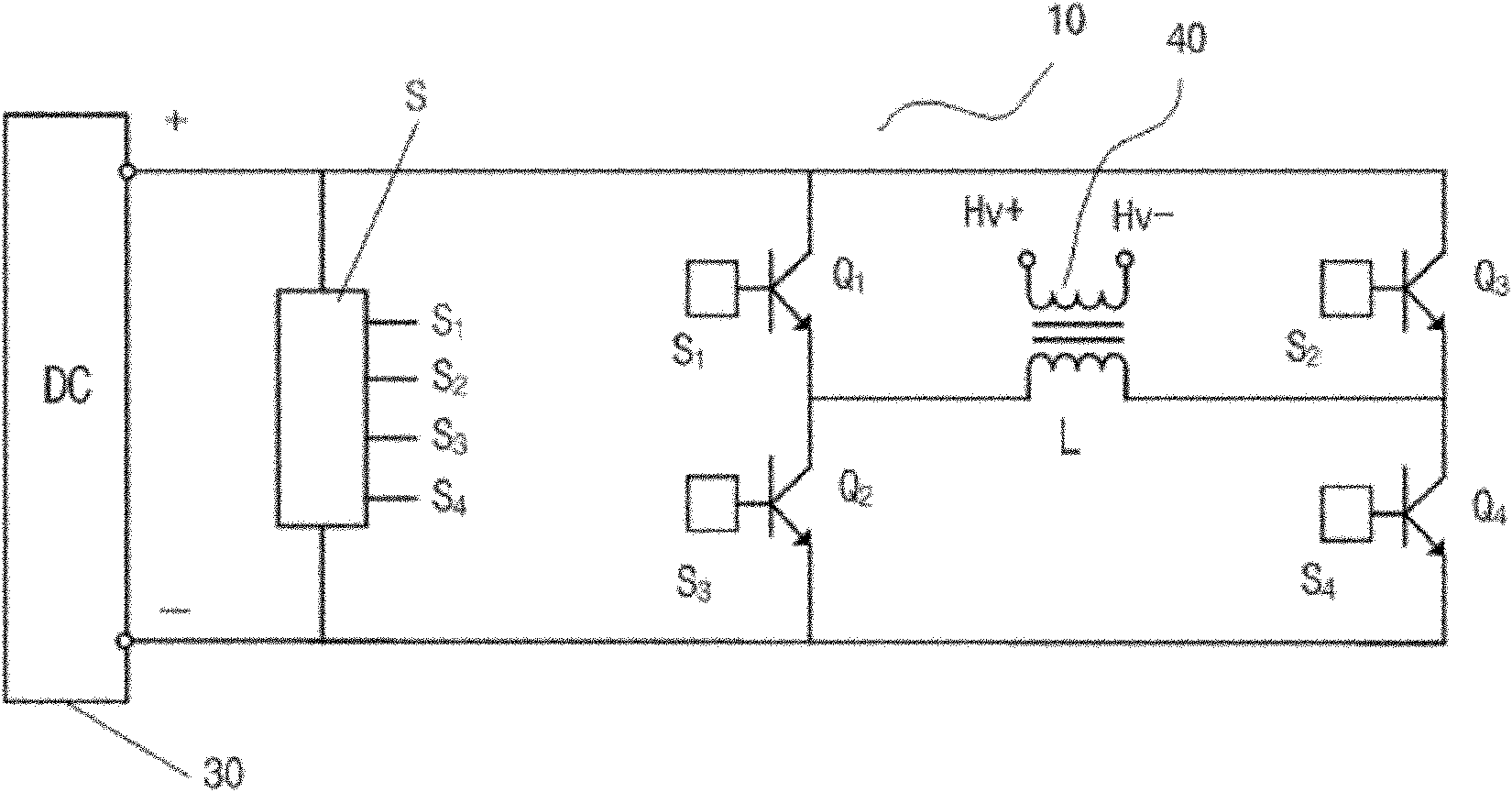

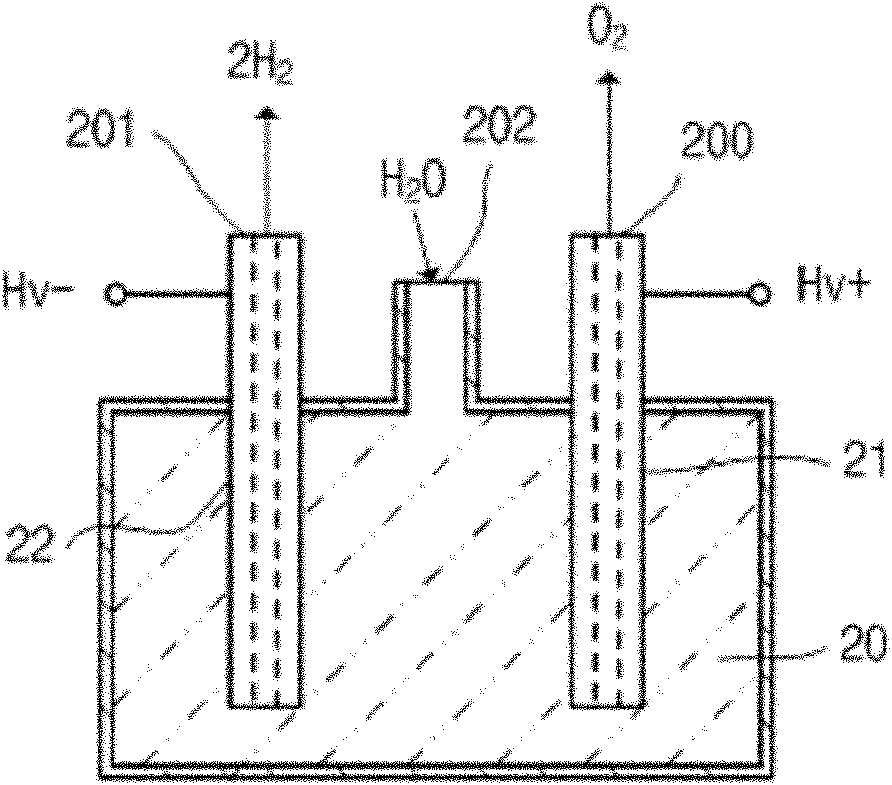

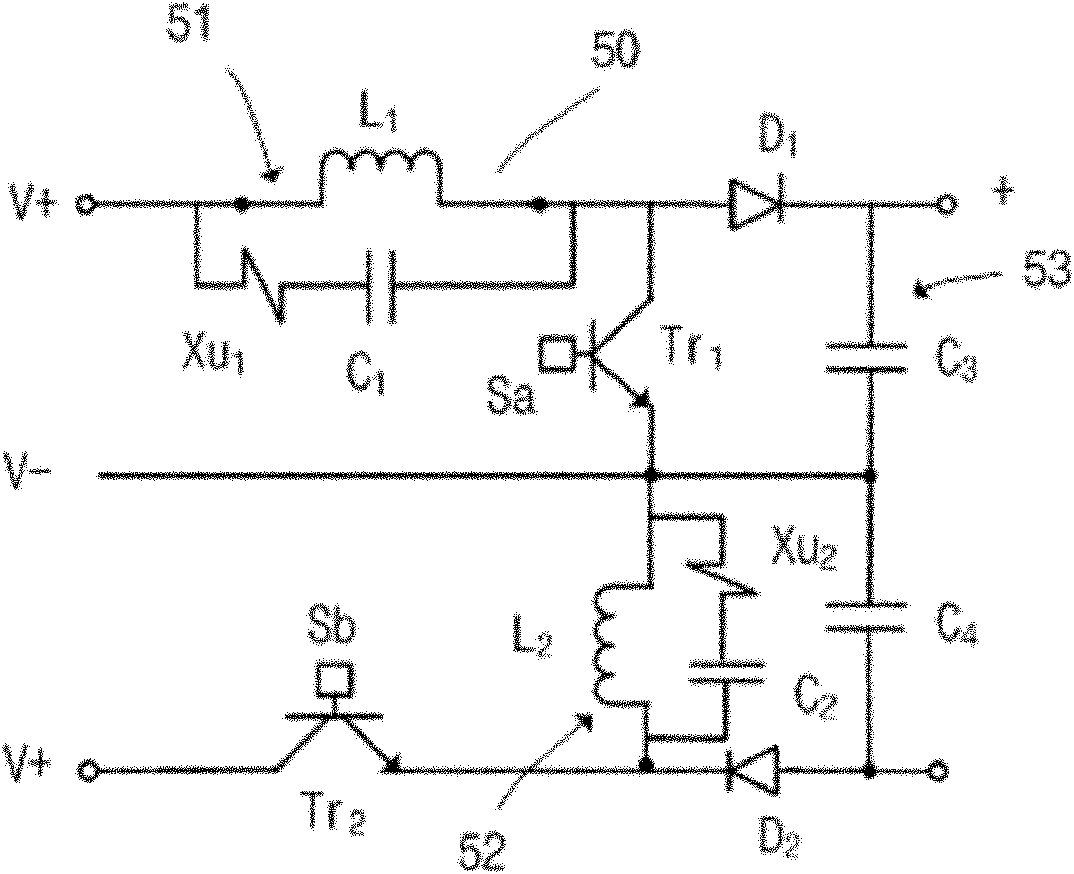

[0033] A resonant oxyhydrogen machine, such as image 3 , 4 , which includes an electrolytic tank 60 and at least one group of voltage electrolysis circuits 50; the group of voltage electrolysis circuits 50 is electrically connected to the battery power supply, and the group of voltage electrolysis circuits 50 has a first infinitely resonant chamber 51 and a first transistor Tr 1 electrically connected, and a second transistor Tr 2 It is electrically connected with a second infinite resonance chamber 52, and the first infinite resonance chamber 51 is connected with a first transistor Tr 1 and the second transistor Tr 2 Connected in parallel with the second infinite resonance chamber 52, the group of voltage electrolysis circuits 50 is also provided with a buffer circuit 53 as the two-pole input end of the electrolysis tank 60; the two terminals electrically connected to the voltage electrolysis circuit 50 of the electrolysis tank 60 are positive Extreme and negative end, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com