Slightly pilling fabric and production method thereof

A raised fabric and production method technology, applied in the field of textiles, can solve the problems of insufficient hand feeling, high weaving requirements, and high raw yarn cost, and achieve the effects of fine and unique hand feeling, saving dye consumption, and improving dyeing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

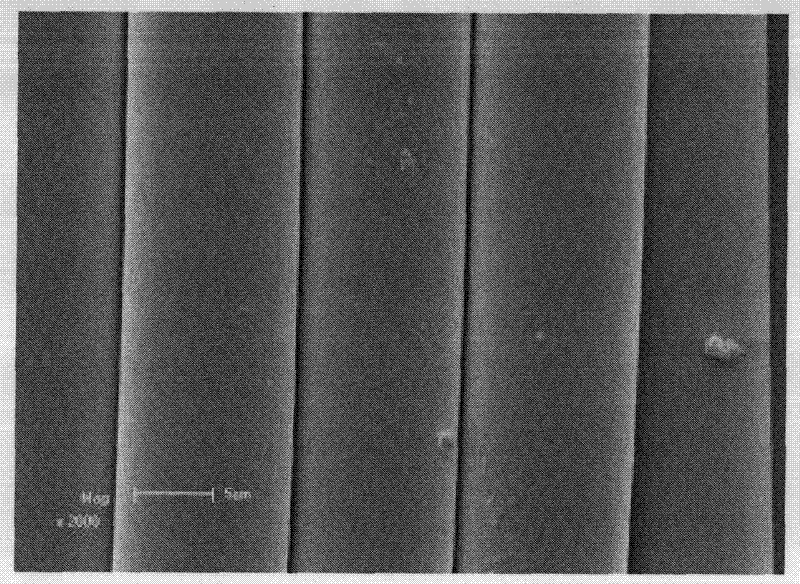

[0030] The warp and weft yarns are made of 20D-20f-FDY nylon yarn with plain weave, and are woven on a Tsudakoma water-jet dobby machine with a weaving tension of 1000N and a rotation speed of 500RPM.

[0031] The above-mentioned gray cloth goes through scouring→presetting→acid treatment→dyeing→drying after dyeing→water-repellent finishing→stenter setting, and finally the finished product is obtained.

[0032] Finishing and processing conditions are:

[0033] Refining: temperature 95°C, speed 80m / min, residence time 5-10s

[0034] Pre-shaping: temperature 180°C, speed 80m / min, set the door width according to the existing width. The wind speed is 30Hz, and the cloth is dropped by curling.

[0035] Acid treatment: acid treatment in liquid flow dyeing machine, acetic acid 38%, 1827 concentration 0.4g / L, liquor ratio 1:20, maximum temperature time 80°C×30min, heating rate 2°C / min, cooling rate 2°C / min min, washed twice with water after acid treatment.

Embodiment 2

[0046] The warp yarn is 20D-20f-NY.FDY, the weft yarn is 30D-22f-NT.CMY, and the weft yarn is made by interlacing 15D-12f-SD.DTY PET (Zhejiang Shengbang Company) and 15D-10F-SD.FDY NY. Nylon accounts for 72%, polyester accounts for 28%, and the weave is 3 / 1 broken twill. It is woven on a Tsudakoma water-jet dobby machine with a weaving tension of 1200N and a rotation speed of 500RPM.

[0047] The above-mentioned gray cloth goes through scouring→presetting→acid treatment→dyeing→drying after dyeing→water-repellent finishing→stenter setting, and finally the finished product is obtained.

[0048] Acid treatment conditions: Acid treatment in liquid flow dyeing machine, formic acid 35%, 1227 concentration 0.5g / L, liquor ratio 1:20, maximum temperature time 70°C×20min, heating rate 2°C / min, cooling rate 2°C / min, washed twice with water after acid treatment. .

[0049] Dyeing conditions: use liquid flow dyeing machine for dyeing, select acid dyes for single-dyeing nylon, heating ra...

Embodiment 3

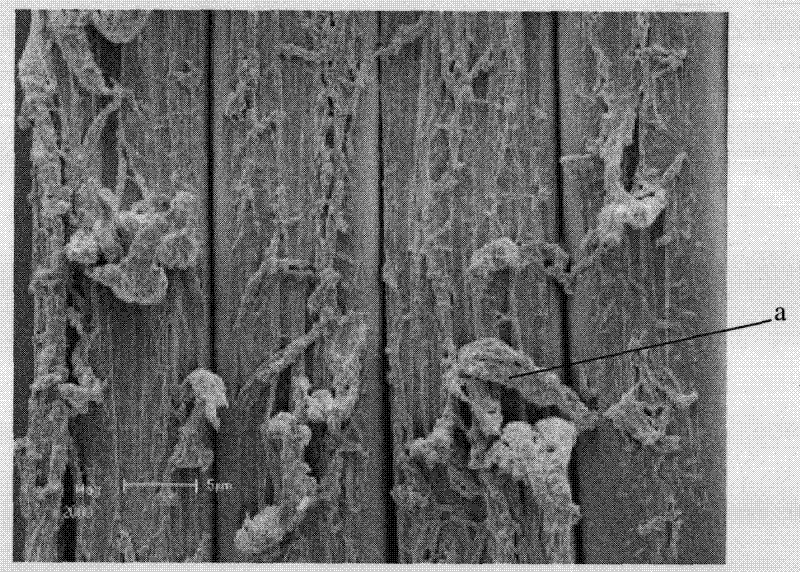

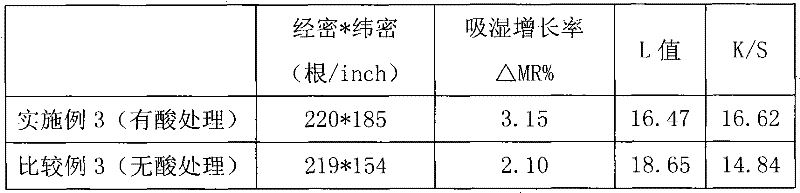

[0057] The warp yarn is 50D-40f-FDY nylon yarn, the weft yarn is 40D-24f-CD.FDY cationic polyester, nylon 64%, cationic polyester 36%, weave is 2 / 1 twill, weaving on Tsudakoma water jet dobby machine, weaving The tension is 1400N, the number of revolutions is 500RPM, and the warp and weft density of gray fabric: 208 threads / inch×146 threads / inch.

[0058] The above-mentioned gray cloth goes through scouring→presetting→acid treatment→dyeing→drying after dyeing→stenter setting, and finally the finished product is obtained.

[0059] Finishing and processing conditions are:

[0060] Acid treatment: carry out acid treatment in the jet dyeing machine, 45% acetic acid, 1227 concentration 0.5g / L, bath ratio 1: 30, maximum temperature time 90 ℃ * 15min, heating rate 2 ℃ / min. The cooling rate is 2°C / min, and the acid treatment is followed by water washing for 2 times.

[0061] Dyeing: Dyeing by airflow dyeing machine, using acid dyes and cationic dyes, the highest dyeing temperature i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com