Automatic calibration system for urea metering jet pumps and calibration method thereof

An automatic calibration system and injection pump technology, applied in the direction of pumps, engine components, combustion engines, etc., can solve the problems of failing to meet the requirements of NOx emission reduction, time-consuming, insufficient response, etc., to improve calibration efficiency and calibration accuracy , automatic control operation is convenient, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

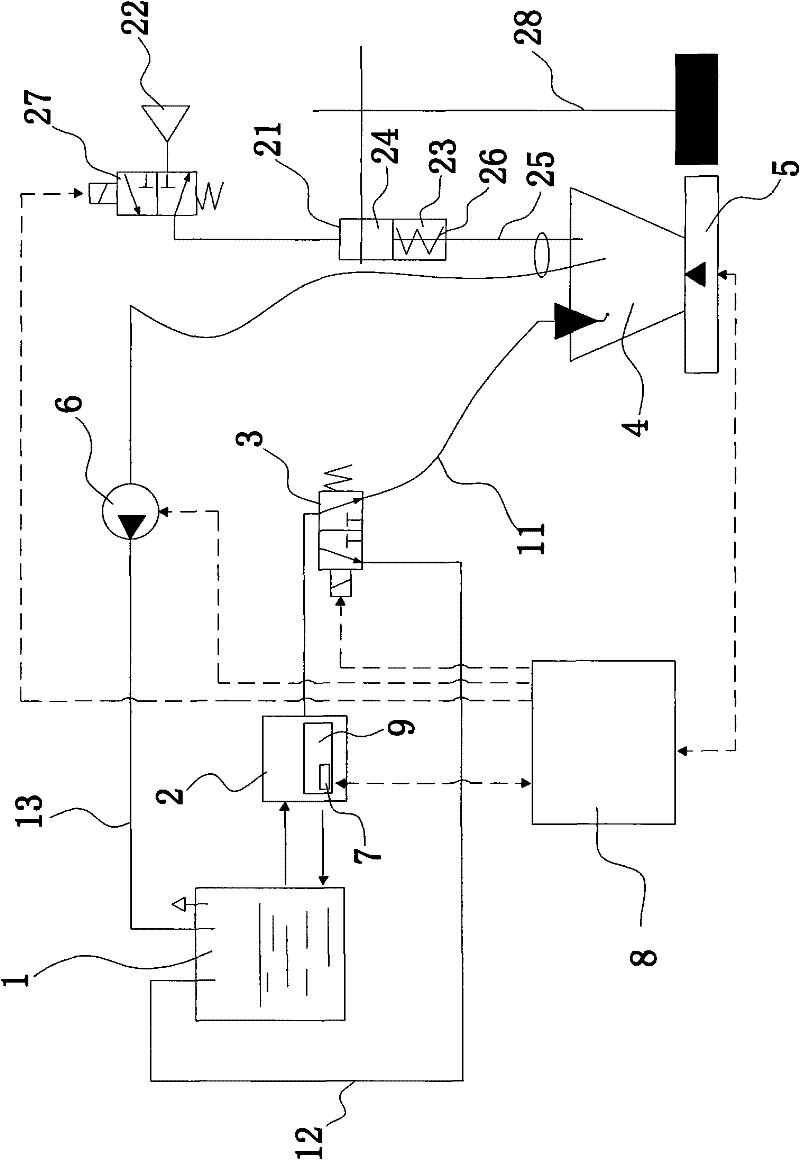

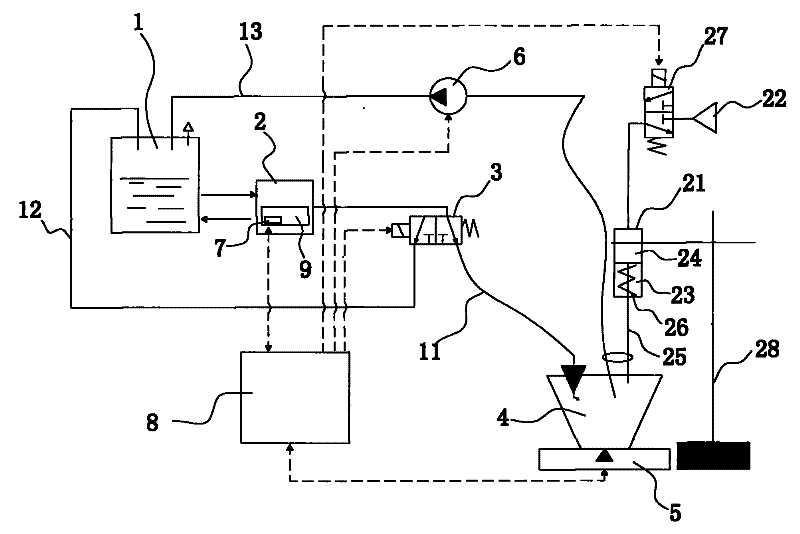

[0019] Such as figure 1 As shown, the present invention relates to an automatic calibration system for a urea metering jet pump, comprising a urea tank 1, a metering jet pump 2, a container 4 and a weighing device 5, and the urea tank 1, the metering jet pump 2 and the container 4 are in pipeline communication , the urea tank 1 is used to store the urea solution, the metering jet pump 2 is used to pump the urea solution in the urea tank, the container 4 is used to store the urea solution, and the weighing device 5 is used to check the container The urea aqueous solution in 4 is weighed.

[0020] The urea metering jet pump automatic calibration system also includes a reversing valve 3, a return line 12 and a control module 8, the reversing valve 3 is arranged downstream of the metering jet pump 2, and the reversing valve 3 is arranged downstr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com