Vacuum ultraviolet light ionization source used for high-flux gas sample analysis

A vacuum ultraviolet light source, vacuum ultraviolet light technology, applied in the ion source/gun, the parts of the particle separator tube, etc., can solve the problems of small illumination range, reduced ion transmission efficiency, ion divergence, etc. Broad application prospects and the effect of improving transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

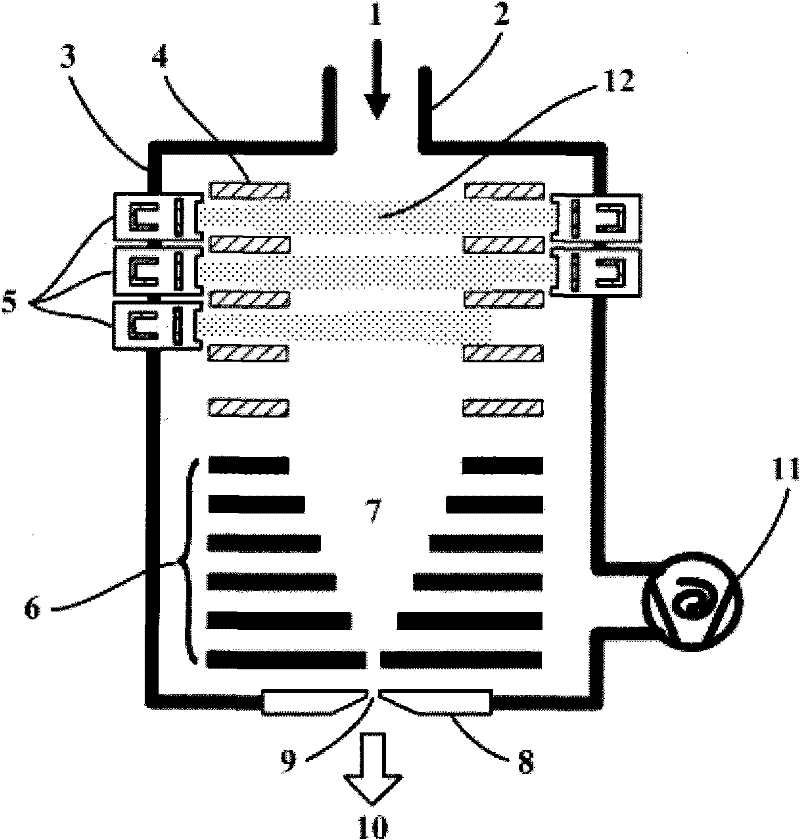

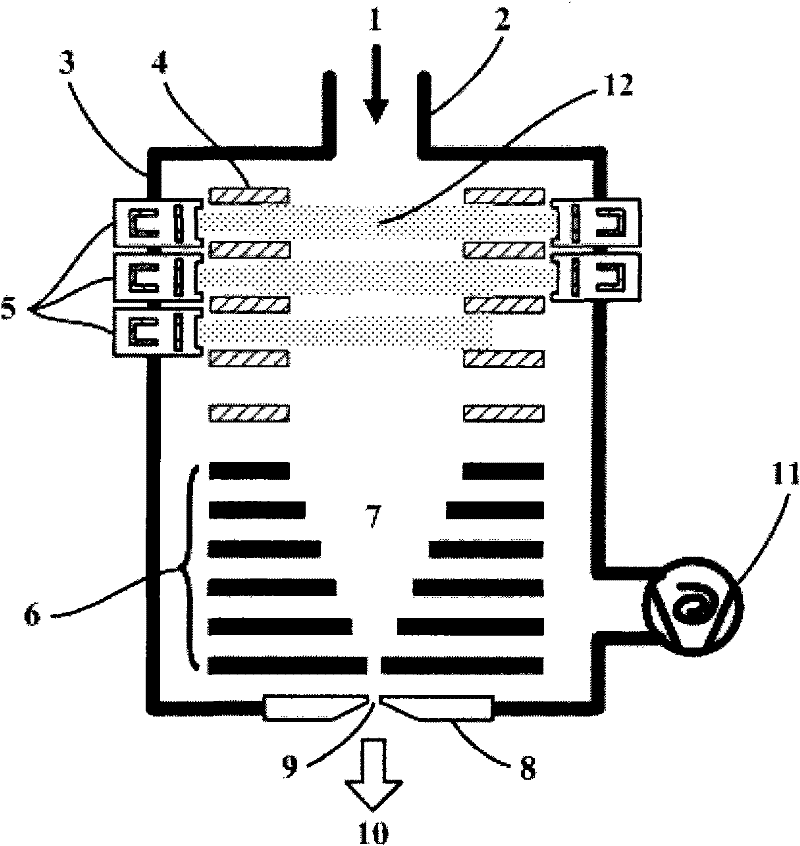

[0018] see figure 1 , is a structural schematic diagram of the present invention. The vacuum ultraviolet photoionization source of the present invention is composed of an ionization source cavity 3 and a vacuum ultraviolet light source 5 .

[0019] A gas outlet is provided on the side wall of the ionization source cavity 3, and the gas outlet is connected to the mechanical vacuum pump 11 through a vacuum pipeline;

[0020] A gas inlet 2 is arranged on the top of the ionization source cavity 3, and the gas sample 1 enters the inside of the ionization source cavity 3 through the gas inlet 2; Shaft, parallel ion extraction electrode 4, ion funnel 6 and differential interface plate 8;

[0021] The ion extracting electrode 4 is a plate structure with two or more through holes in the center, coaxial and parallel; the vacuum ultraviolet light source 5 is arranged on the side wall of the ionization source cavity 3, and the vacuum ultraviolet light source 5 emits The vacuum ultravio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com