Trench isolation structure and forming method for same

一种沟槽隔离、沟槽的技术,应用在半导体器件、电气元件、电路等方向,能够解决漏电流、影响半导体器件性能等问题,达到改善性能、结合紧密、减小尺寸的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

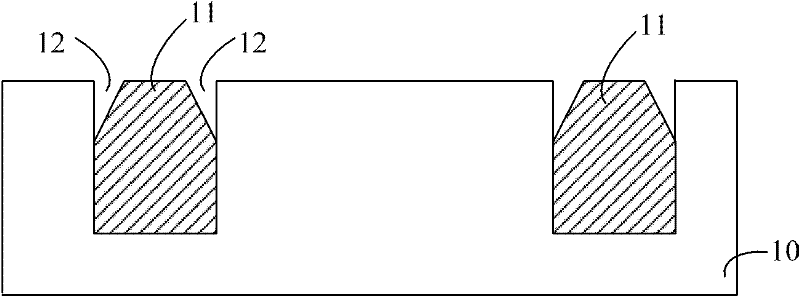

[0047] In the shallow trench isolation structure formed in the prior art, side trenches exist between the surface of the dielectric layer filled in the shallow trench and the surface of the semiconductor substrate, which will generate leakage current and affect the performance of the semiconductor device.

[0048] In the shallow trench isolation structure of the prior art, the material used for the dielectric layer is an amorphous material, such as silicon oxide, silicon nitride, etc. The inventors have found through research that since the material of the semiconductor substrate is a crystalline material, the amorphous material The combination between the dielectric layer and the semiconductor substrate of the crystalline material is not tight enough, so that it is easy to generate side grooves at the junction of the amorphous material and the crystalline material during the planarization and subsequent cleaning processes, resulting in leakage current and affecting the performa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com