Glass/resin laminate, and electronic device using same

A technology for electronic equipment and laminates, applied in glass/slag layered products, synthetic resin layered products, electronic equipment, etc., can solve the problem of poor operability of glass substrates, chemical resistance and moisture permeability of resin substrates. problems, etc., to achieve the effects of excellent surface flatness and heat resistance, improved workability, and warpage suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

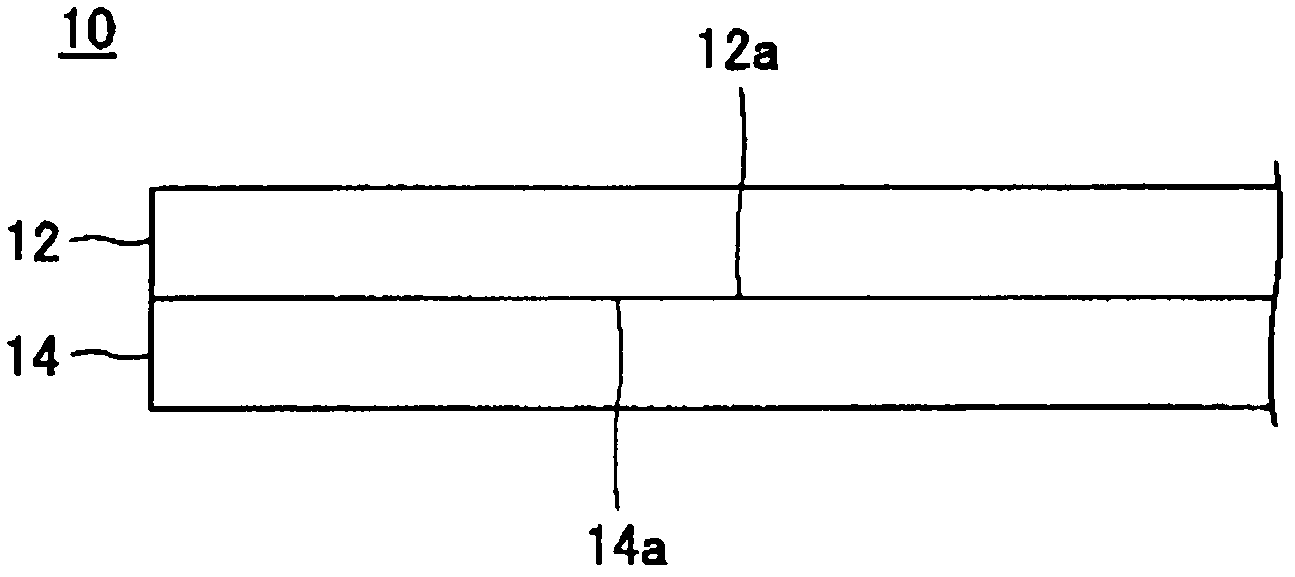

[0193] In embodiment 1, as test piece, manufacture figure 1 A glass / resin laminate 10 is shown.

[0194] (Cleaning process of glass substrate 12)

[0195] As the glass substrate 12 , an alkali-free glass substrate (manufactured by Asahi Glass Co., Ltd., AN100) obtained by a float method with a width of 500 mm and a thickness of 70 μm was used. The average coefficient of linear expansion of the glass substrate 12 is 38×10 -7 / °C.

[0196] Both surfaces of the glass substrate 12 are activated by UV cleaning. Then, the glass substrate 12 is wound up into a roll shape while laminating protective films on both surfaces of the glass substrate 12 .

[0197] (Surface treatment of glass substrate 12)

[0198] While unwinding the glass substrate 12 wound into a roll, the protective films laminated on both sides of the glass substrate 12 are peeled off, and the surface 12 a of the glass substrate 12 that contacts the resin layer 14 is subjected to silane coupling treatment. Specif...

Embodiment 2

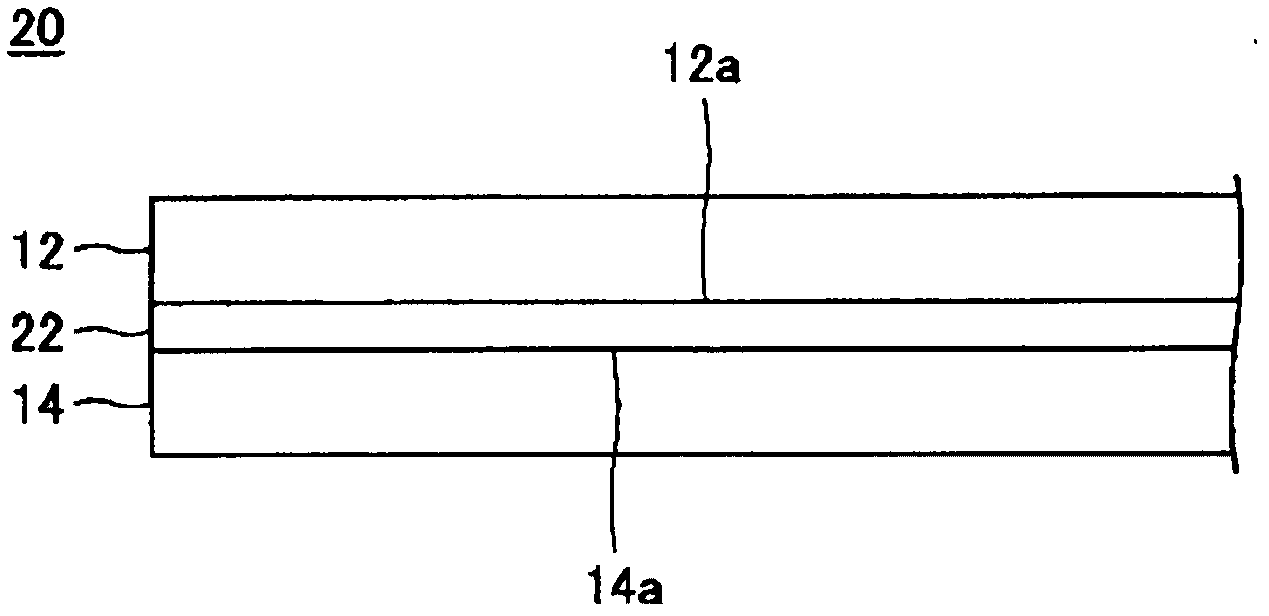

[0210] In embodiment 2, as test piece, manufacture figure 2 A glass / resin laminate 20 is shown.

[0211] (glass substrate 12)

[0212] As the glass substrate 12 , a non-alkali glass substrate (manufactured by Asahi Glass Co., Ltd., AN100) obtained by a float method with a length of 500 mm×a width of 500 mm×a thickness of 45 μm was used. The average coefficient of linear expansion of the glass substrate 12 is 38×10 -7 / °C.

[0213] (resin layer 14)

[0214] As the resin layer 14 , a heat-resistant polyimide film having a length of 500 mm×a width of 500 mm×a thickness of 30 μm produced in the same manner as in Example 1 was used. The average linear expansion coefficient of the heat-resistant polyimide film is 30×10 -7 / °C, and the difference between the average linear expansion coefficient of the glass substrate 12 is 8×10 -7 / °C.

[0215] (Manufacture of thermoplastic polyimide film as adhesive layer 22)

[0216] After replacing nitrogen in the reaction vessel equipped...

Embodiment 3

[0231] In embodiment 3, manufacture as test piece with the method different from embodiment 1 figure 1 A glass / resin laminate 10 is shown.

[0232] (Cleaning process of glass substrate 12)

[0233] As the glass substrate 12 , an alkali-free glass substrate (manufactured by Asahi Glass Co., Ltd., AN100) obtained by a float method with a width of 500 mm and a thickness of 70 μm was used. The average coefficient of linear expansion of the glass substrate 12 is 38×10 -7 / °C.

[0234] Both surfaces of the glass substrate 12 are activated by UV cleaning. Then, the glass substrate 12 is wound up into a roll shape while laminating protective films on both surfaces of the glass substrate 12 .

[0235] (Surface treatment of glass substrate 12)

[0236] While unwinding the glass substrate 12 wound into a roll, the protective films laminated on both sides of the glass substrate 12 are peeled off, and the surface 12 a of the glass substrate 12 that contacts the resin layer 14 is subj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com