Up-flow multilayer sludge bed treatment device

A technology of treatment device and sludge bed, applied in the field of sludge treatment device, can solve the problems of waste of effective sludge storage volume, unfavorable sludge disposal method, large area of facilities, etc., so as to increase biological load and pollution. The effect of sludge digestion ability, improving sludge treatment ability and prolonging residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

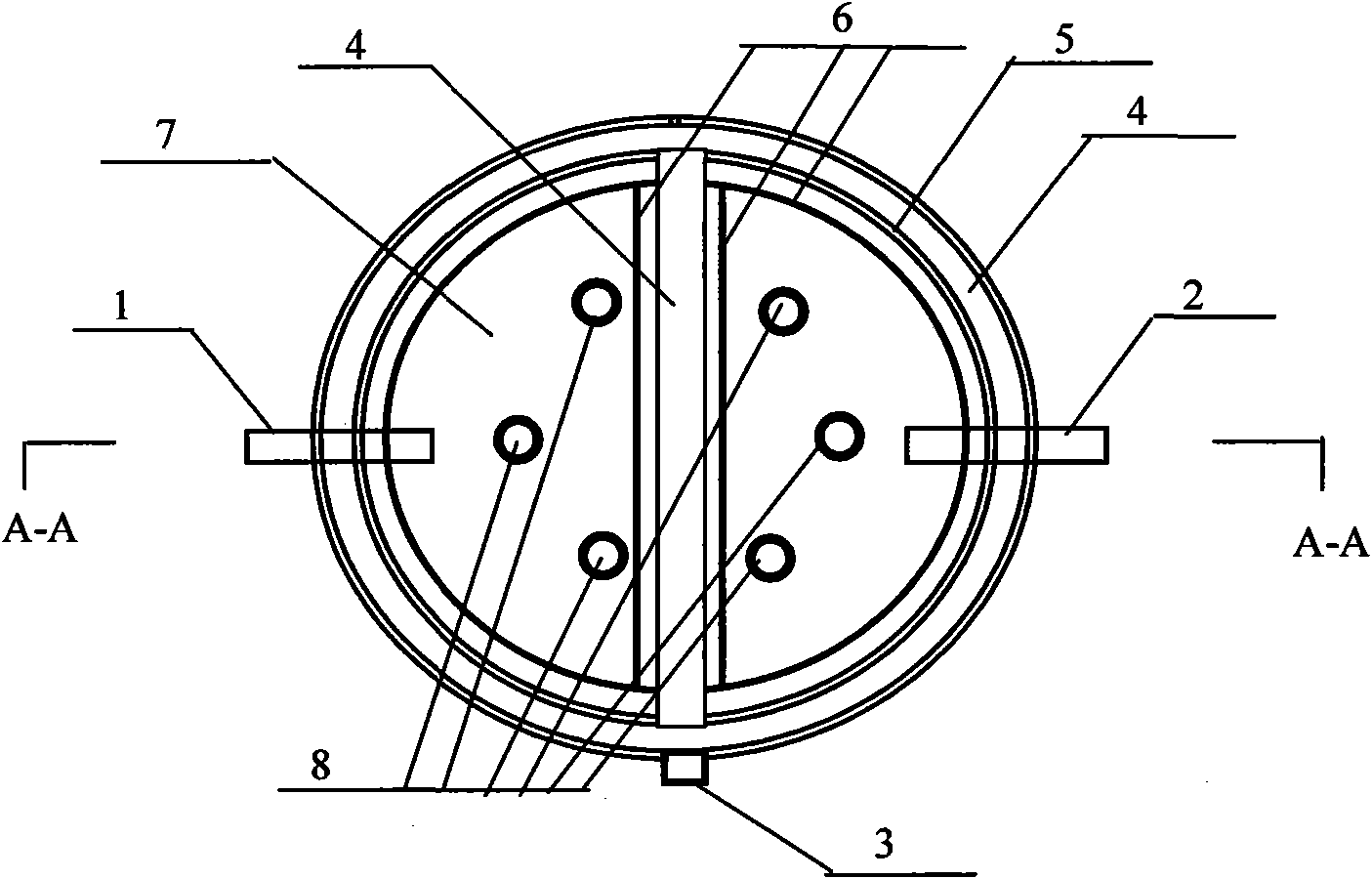

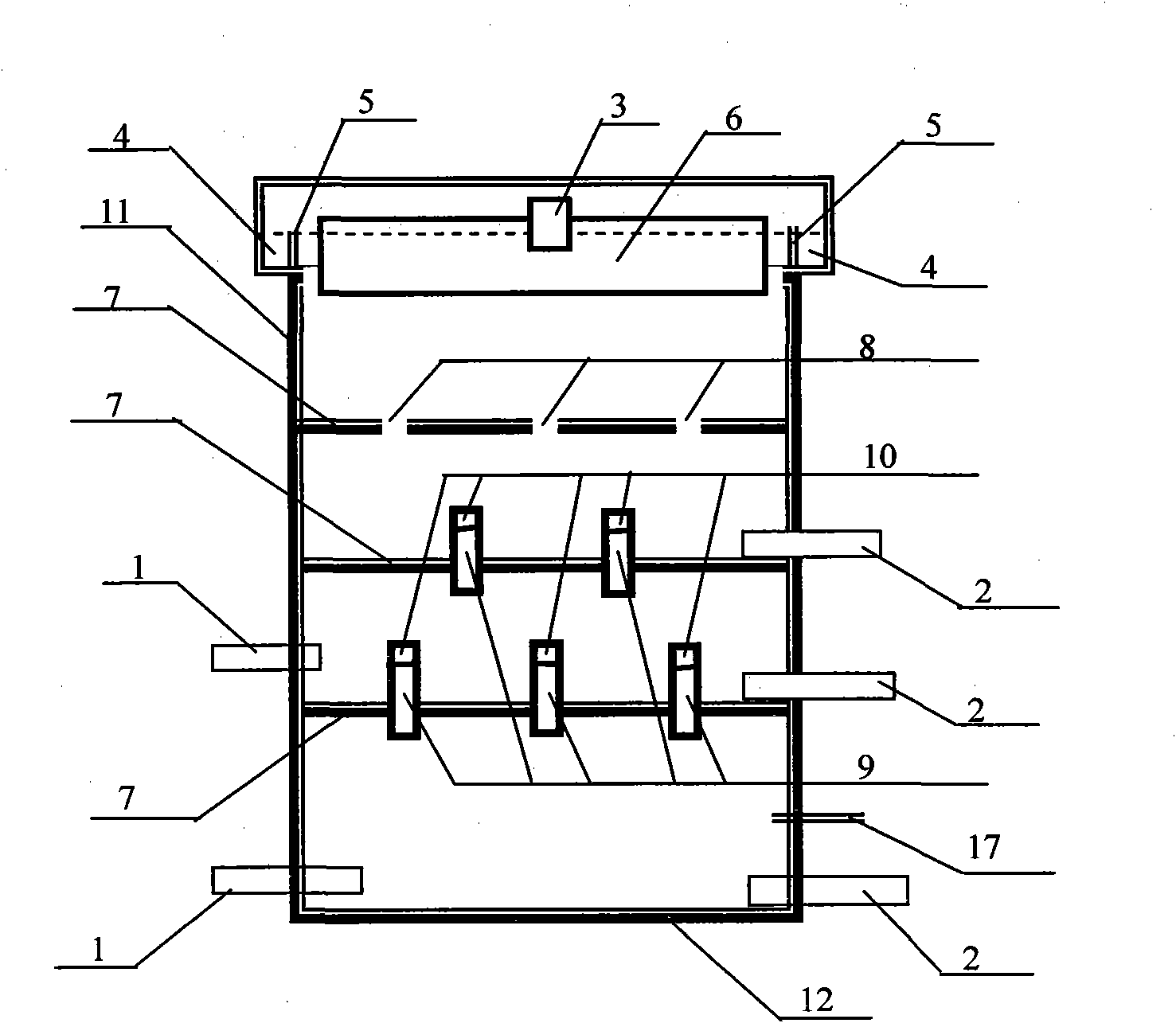

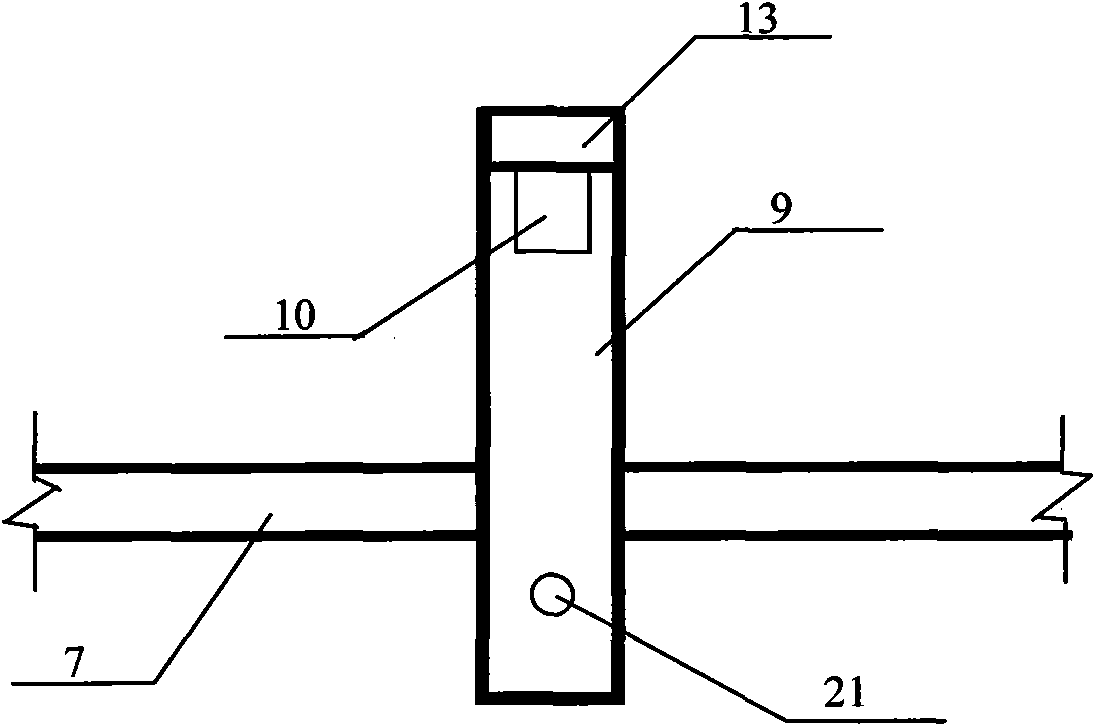

[0014] like figure 1 , 2 The first scheme shown in 3 and 3 is a cylindrical up-flow sludge treatment device with an open top surface of the tank body. The tank body adopts a reinforced concrete structure. The bottom of the tank is a flat tank bottom 12. 7 is divided into four pool spaces, the uppermost layered floor 7 is provided with a plurality of water passage openings 8, and the lower two layered floor plates 7 are provided with a plurality of space through water distribution pipes 9, and the space through the water distribution pipe 9. There is a radial outlet 10, the upper part of the radial outlet 10 is a through-pipe top cover 13, there is at least one ventilation hole 21 on the through-tube 9 in the space below the layered floor 7, and at least one mud water inlet pipe is installed on the side wall 11 of the pool body. 1. Each layer of the pool space with sludge deposition is provided with a sludge discharge pipe 2, and a collection channel groove 4 is arranged aroun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com