Preparation method for linear nanometre hydroxylapatite

A nano-hydroxyapatite, linear technology, applied in the field of nano-materials, can solve the problems of unsuitable for large-scale production, high price, unsuitable phage for tissue repair, etc., achieving simple preparation method, inhibition of agglomeration, mild and controllable conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a method for preparing linear nano-hydroxyapatite, comprising the following steps:

[0027] Concentrating the silk fibroin aqueous solution of the first mass concentration to the second mass concentration and then sealing and cultivating to obtain the silk fibroin nanofiber aqueous solution;

[0028] The silk fibroin nanofiber aqueous solution is mixed with a phosphate source and a calcium source, and the linear nano-hydroxyapatite is obtained after reaction.

[0029] In the present invention, firstly, the silk fibroin aqueous solution of the first mass concentration is concentrated to the second mass concentration, and then sealed and cultivated. During this process, the silk fibroin self-assembles into silk fibroin nanofibers to obtain the silk fibroin nanofiber aqueous solution; and then Using the silk fibroin nanofiber aqueous solution as a template, nano-hydroxyapatite is synthesized on the surface of silk fibroin nanofibers. The interaction ...

Embodiment 1

[0061] The silk at a mass concentration of 0.5% Na 2 CO 3 Boil in the solution for 60 minutes at 100°C to remove sericin on the outside of the silk; wash the obtained product with deionized water, repeat 3 times, and dry at 60°C to obtain silk fibroin;

[0062] Dissolve 27 grams of silk fibroin in 100 mL of lithium bromide solution, put the obtained silk fibroin solution in a dialysis bag and immerse it in deionized water for dialysis for 3 days, during which the water is changed every two hours to obtain a pure silk fibroin solution. The mass concentration is 5.9%;

[0063] Slowly dry the silk fibroin solution at room temperature under a fume hood, increase the silk fibroin concentration to 25%, and then place it at 4°C for 2 days to obtain a silk fibroin nanofiber solution;

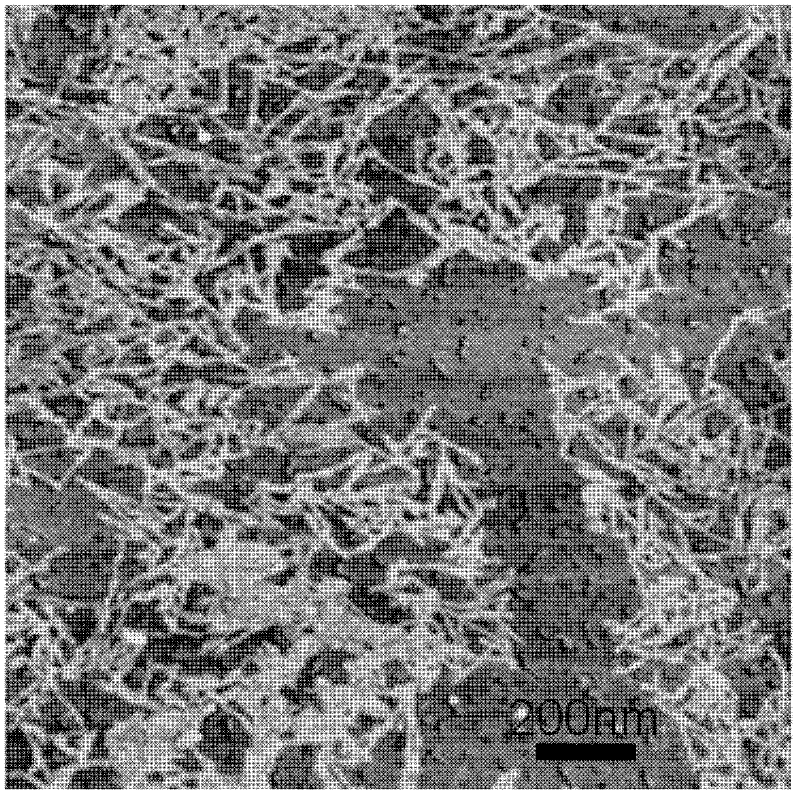

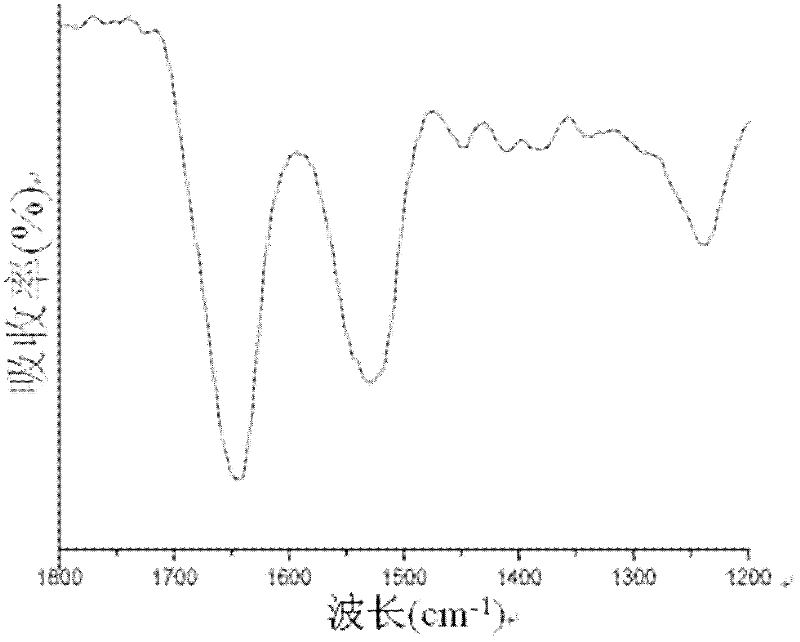

[0064] The silk fibroin nanofiber solution is carried out atomic force microscope analysis and infrared spectrum analysis, the results can be found in figure 1 and figure 2 , figure 1 The atomic f...

Embodiment 2

[0069] The silk at a mass concentration of 0.5% Na 2 CO 3 Boil in the solution for 60 minutes at 100°C to remove sericin on the outside of the silk; wash the obtained product with deionized water, repeat 3 times, and dry at 60°C to obtain silk fibroin;

[0070] Dissolve 27 grams of silk fibroin in 100 mL of lithium bromide solution, put the obtained silk fibroin solution in a dialysis bag and immerse it in deionized water for dialysis for 3 days, during which the water is changed every two hours to obtain a pure silk fibroin solution. The mass concentration is 5.9%;

[0071] Slowly dry the silk fibroin solution at room temperature under a fume hood, increase the silk fibroin concentration to 40%, and then place it at 4°C for 18 days to obtain a silk fibroin nanofiber solution;

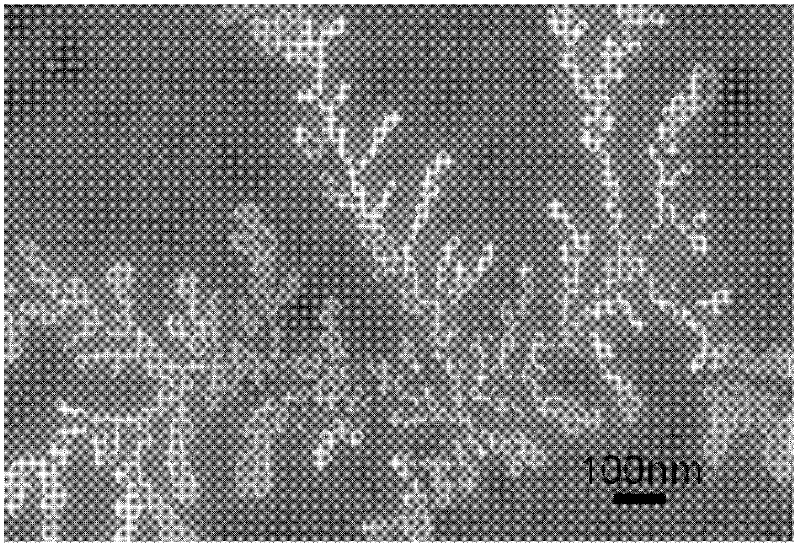

[0072] The atomic force microscope analysis and infrared spectrum analysis were carried out on the silk fibroin nanofiber solution, and the results showed that the silk fibroin nanofiber was obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com