Method for separating milk-derived whey protein by peg/phosphate two-phase system

A two-phase aqueous system and whey protein technology, applied in the field of PEG/phosphate two-phase aqueous system to separate milk-derived whey protein α-La and β-Lg, to achieve mild operating conditions, low price, and easy industrial production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

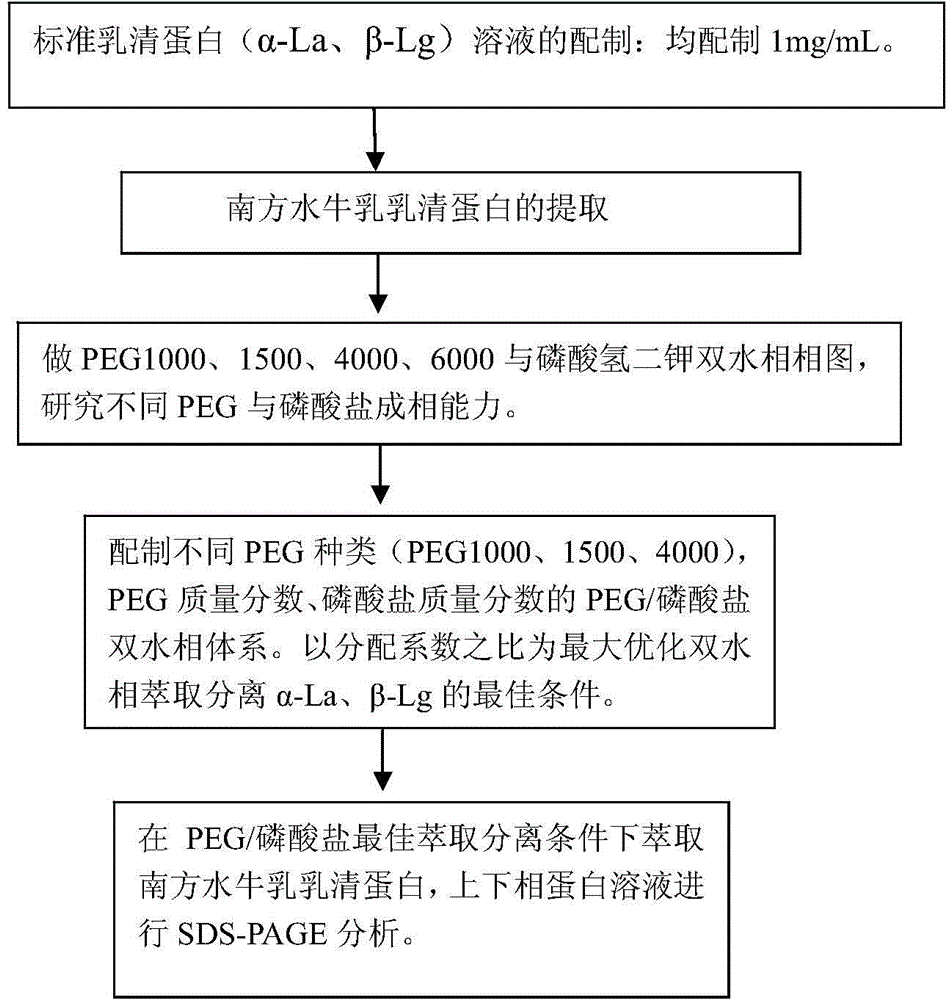

[0039] Whey protein was separated by PEG / phosphate two-phase system. The separation steps are as follows:

[0040] (1) Preparation of standard whey protein solution: standard α-La solution (1mg / mL); standard β-Lg solution (1mg / mL).

[0041] (2) Southern buffalo milk whey protein extraction: Commercially available buffalo milk was centrifuged at 4000r / min at 4°C for 20 minutes to skim, and the upper layer of fat was discarded. The skim milk was adjusted to pH 4.6 with 5M HCl, and stood for 30min at 4000r / min at 4°C. Centrifuge for 20 minutes, discard the precipitate, filter the supernatant with a 0.22 μm filter membrane, dialyze against distilled water at 4°C overnight, freeze-dry, and store in a freezer at -20°C.

[0042] (3) Use the cloud point method to draw the phase diagram of the two-phase aqueous system. The experimental method is as follows: Take a certain mass of inorganic salt (m1) and add a certain amount of distilled water (m2), dissolve, and constant volume, and c...

Embodiment 2

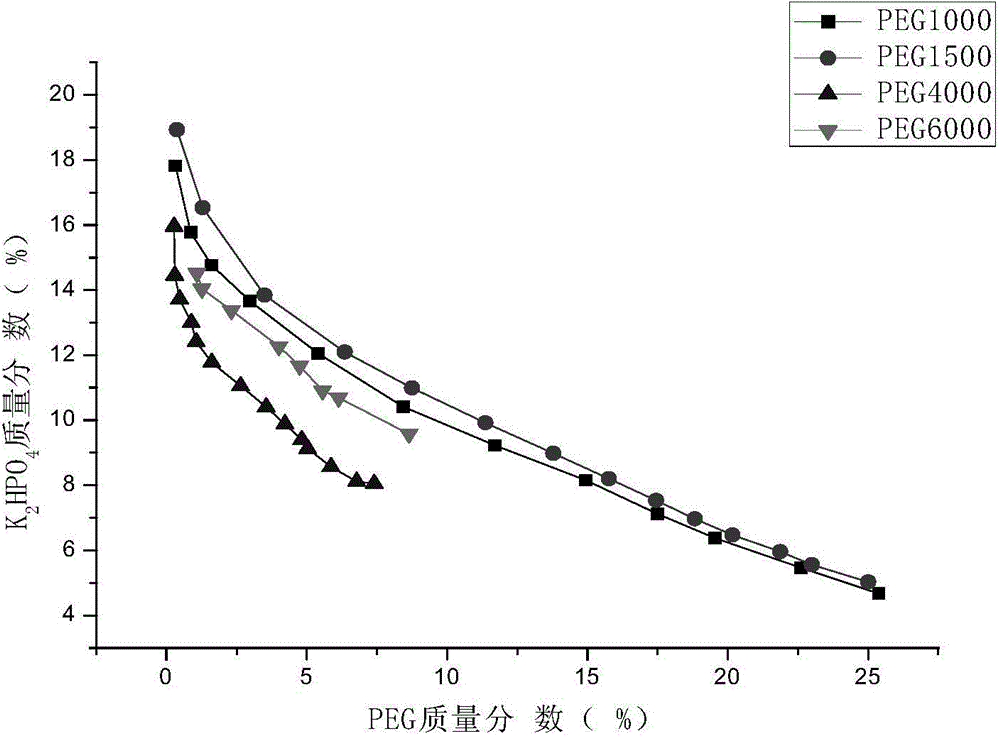

[0053] Embodiment 2: analyze the phase forming ability of four kinds of PEG and phosphate

[0054] In the step (3) of Example 1, the cloud point method was used to make the two-phase phase diagram of PEG1000, 1500, 4000, 6000 and dipotassium hydrogen phosphate to understand the phase-forming ability of the four PEGs and phosphate. The longer the two-node line in the aqueous two phase diagram, the stronger the phase separation ability of the two substances. The phase diagram of PEG and phosphate is as follows figure 2 shown.

Embodiment 3

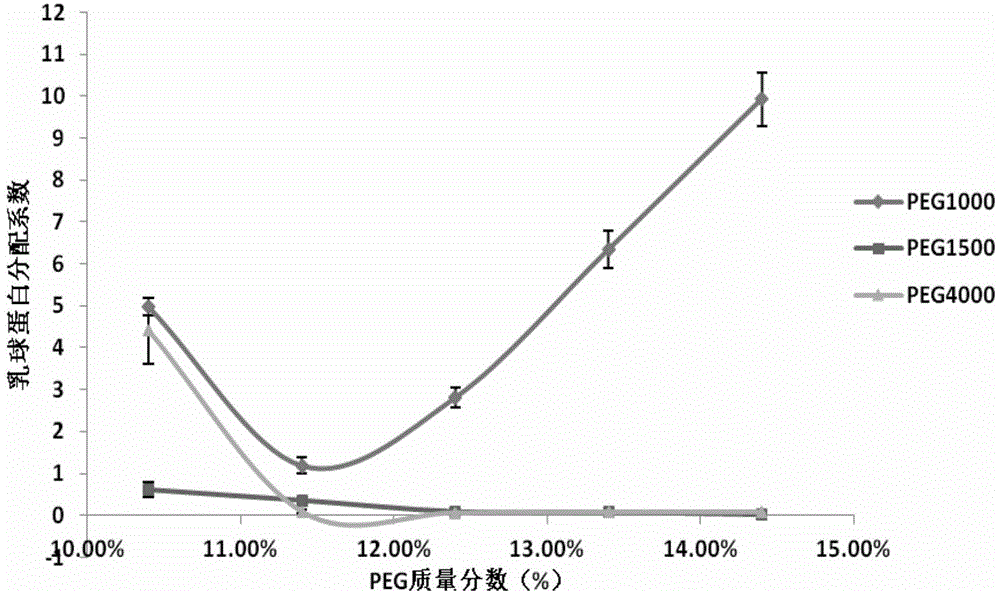

[0055] Embodiment 3: Determination of PEG mass fraction in the best PEG type and system

[0056] Prepare the PEG / phosphate two-phase system with PEG mass fractions of 10.4%, 11.4%, 12.4%, 13.4%, and 14.4%, PEG types of 1000, 1500, and 4000, phosphate concentration of 14.8%, and system pH of 7.3 For the extraction effect of α-La and β-Lg, calculate the distribution coefficient and recovery rate of α-La and β-Lg respectively. The larger the ratio of the distribution coefficient of α-La and β-Lg, the better the separation effect. Best PEG species and PEG quality scores. Among them, the effect of PEG type and mass fraction on the distribution coefficient of β-Lg, and the effect of PEG type and mass fraction on the distribution coefficient of α-La are shown in Fig. image 3 and Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com