Fracturing fluid thickening agent and fracturing fluid containing the same

A fracturing fluid thickener and modification technology, applied in the fields of polysaccharide thickener, fracturing fluid thickener, and fracturing fluid, can solve the problem of lack of vegetable gum fracturing thickener and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

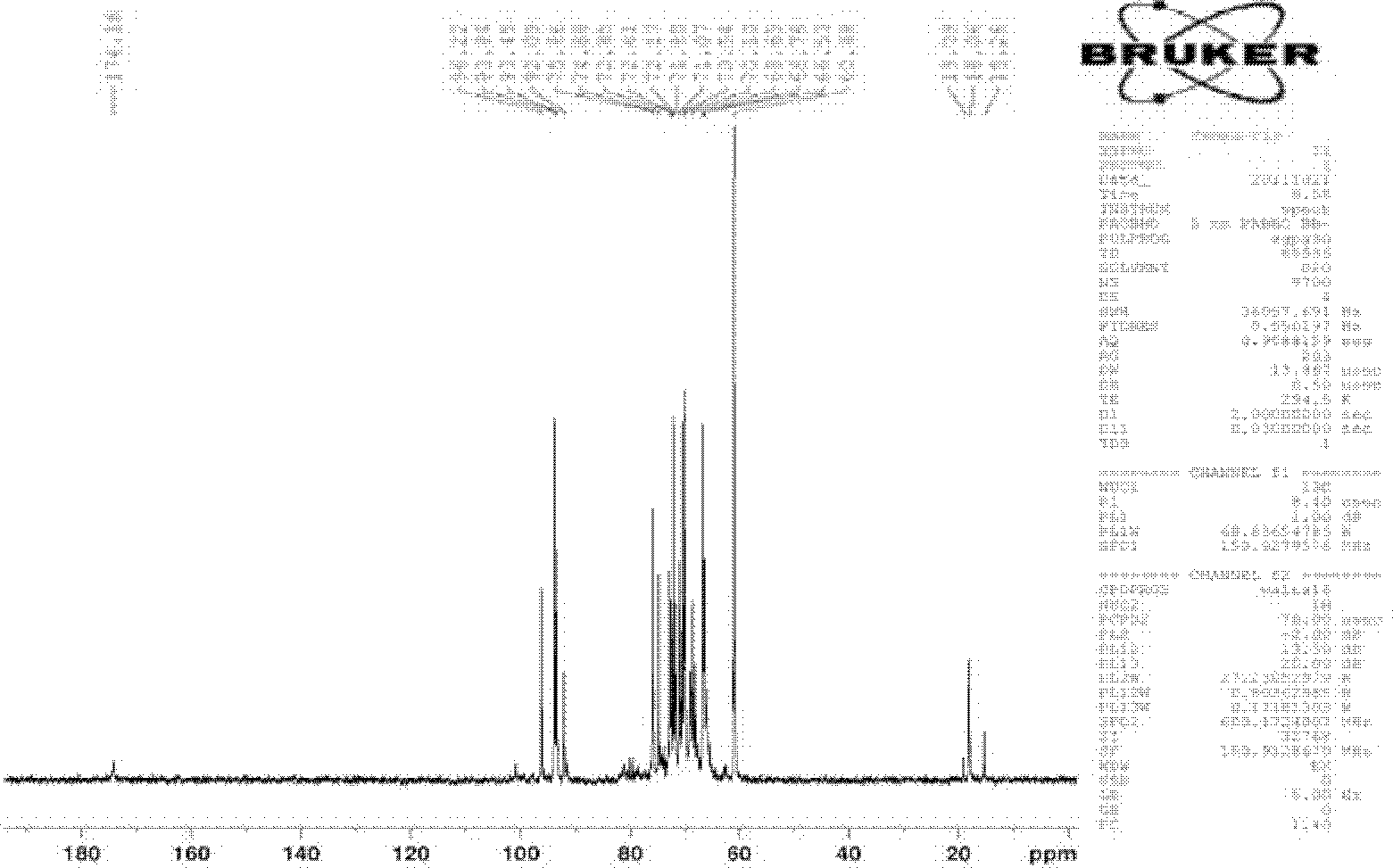

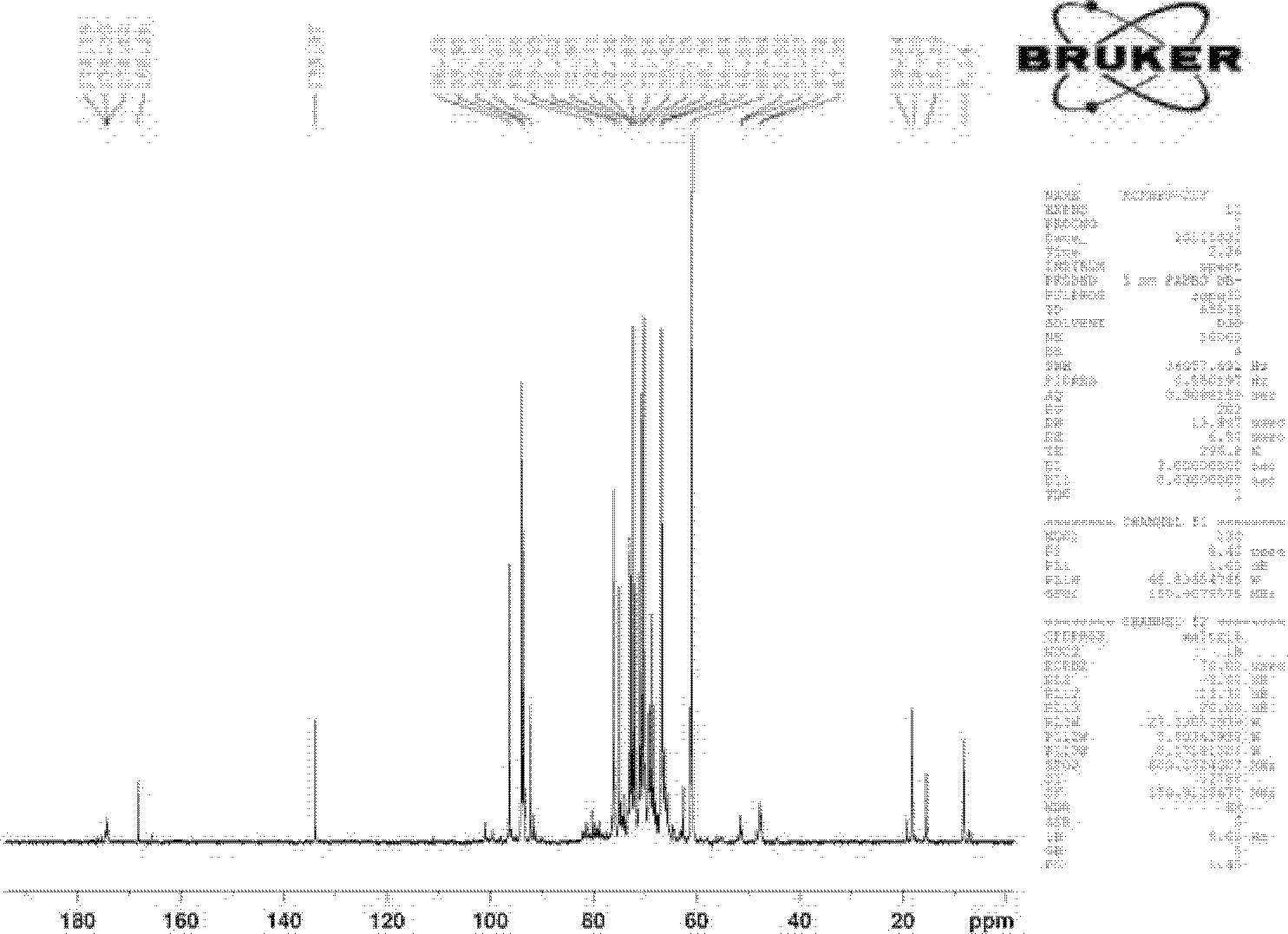

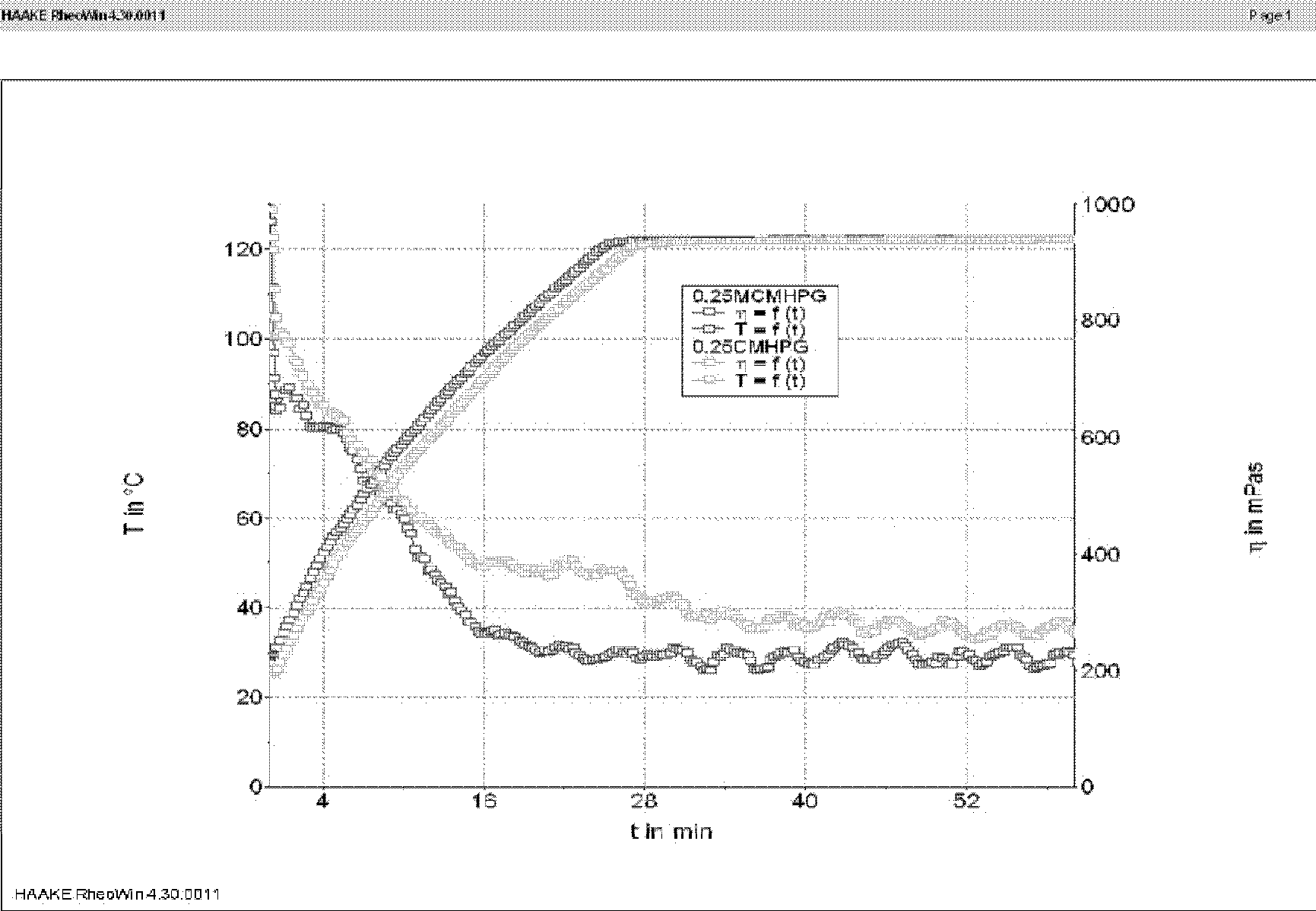

Image

Examples

Embodiment

[0089] The thickener of the present invention and its production process are described below with regard to specific examples of implementation.

[0090] Case 1:

[0091] Put 100 kg of hydroxypropyl guar gum in 600-700 liters of isopropanol, pass N 2 For 30 minutes, under low temperature conditions, add 32 kg of 20% sodium hydroxide solution dropwise, and after stirring for 30 minutes, add 35 kg of 75% sodium chloroacetate dropwise, heat up to 75°C, stir for 180 minutes, and use citric acid or acetic acid Neutralization, filtration, washing, drying, crushing, and finished products. Properties see properties examples.

[0092] Case 2:

[0093] Put 100 kg carboxymethyl hydroxypropyl guar gum in 600-700 liters of isopropanol, pass N 2 30 minutes, under the low temperature situation, dropwise add 32 kilograms of 20% sodium hydroxide solution, after stirring and maturing for 30 minutes, add dropwise 60 kilograms of 25% sodium chloroethylsulfonate, be warming up to 80 ℃, stir an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com