Environmentally-friendly double-component high temperature-resistant conveyer belt bonding agent and preparation method thereof

A two-component, high-temperature-resistant technology, applied in the direction of adhesives, grafted polymer adhesives, adhesive types, etc., can solve the problems of short life of joints, poor flexibility of joints, and reduced strength, so as to improve the adhesive strength. Bonding strength, enhanced bonding strength, and the effect of improving temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

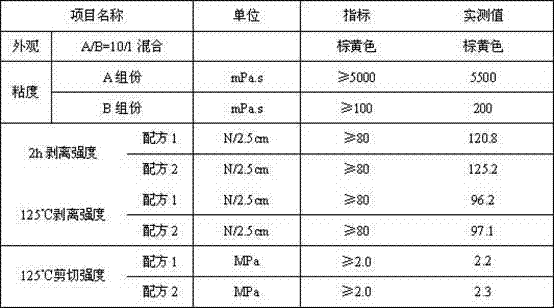

example 1

[0024] Component A

[0025] Neoprene 100 Methacrylic acid 15 Benzoyl peroxide 0.15

[0026] Hydroquinone 0.1 Alkyl benzoic acid resin 50 Activated magnesium oxide 5

[0027] Triethanolamine 0.5 Zinc Oxide 6 Aluminum Hydroxide 15

[0028] Ethyl acetate 200 butanone 250 dimethyl carbonate 180

[0029] Pigment 0.5

[0030] Component B

[0031] Polyisocyanate 20 Tripolythiocyanate 2 Ethyl acetate 60

[0032] Inhibitor 0.1

example 2

[0034] Component A

[0035] Neoprene 100 Methacrylic acid 20 Benzoyl peroxide 0.16

[0036] Hydroquinone 0.1 Alkyl benzoic acid resin 60 Activated magnesium oxide 5

[0037] Triethanolamine 0.5 Zinc Oxide 6 Aluminum Hydroxide 15

[0038] Ethyl acetate 200 Butanone 250 Dimethyl carbonate 180

[0039] Pigment 0.5

[0040] Component B

[0041] Polyisocyanate 20 Tripolythiocyanate 2 Ethyl acetate 60

[0042] Inhibitor 0.1

[0043] Both recipes are produced in the same way, take Example 1 as an example:

[0044] A component preparation method:

[0045] (1) Polymerization reaction: Add 100 parts of ethyl acetate, 250 parts of methyl ethyl ketone and 100 parts of dimethyl carbonate to a polymerization kettle equipped with a condenser and an anchor cross-blade stirrer. Add 100 parts of neoprene; stir for 2 hours until it is completely dissolved, then add 15 parts of methacrylic acid. Then control the stirring speed of the mixture to 80 rpm, and flush the polymerization t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com