Selective area hetero-epitaxial substrate structure, preparation thereof and epitaxial layer growing method

A technology of heterogeneous epitaxy and substrate structure, applied in the direction of chemical instruments and methods, single crystal growth, single crystal growth, etc., can solve the problems of high cost, complexity, and many processes, so as to simplify the growth steps and process, improve the effective The effect of width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

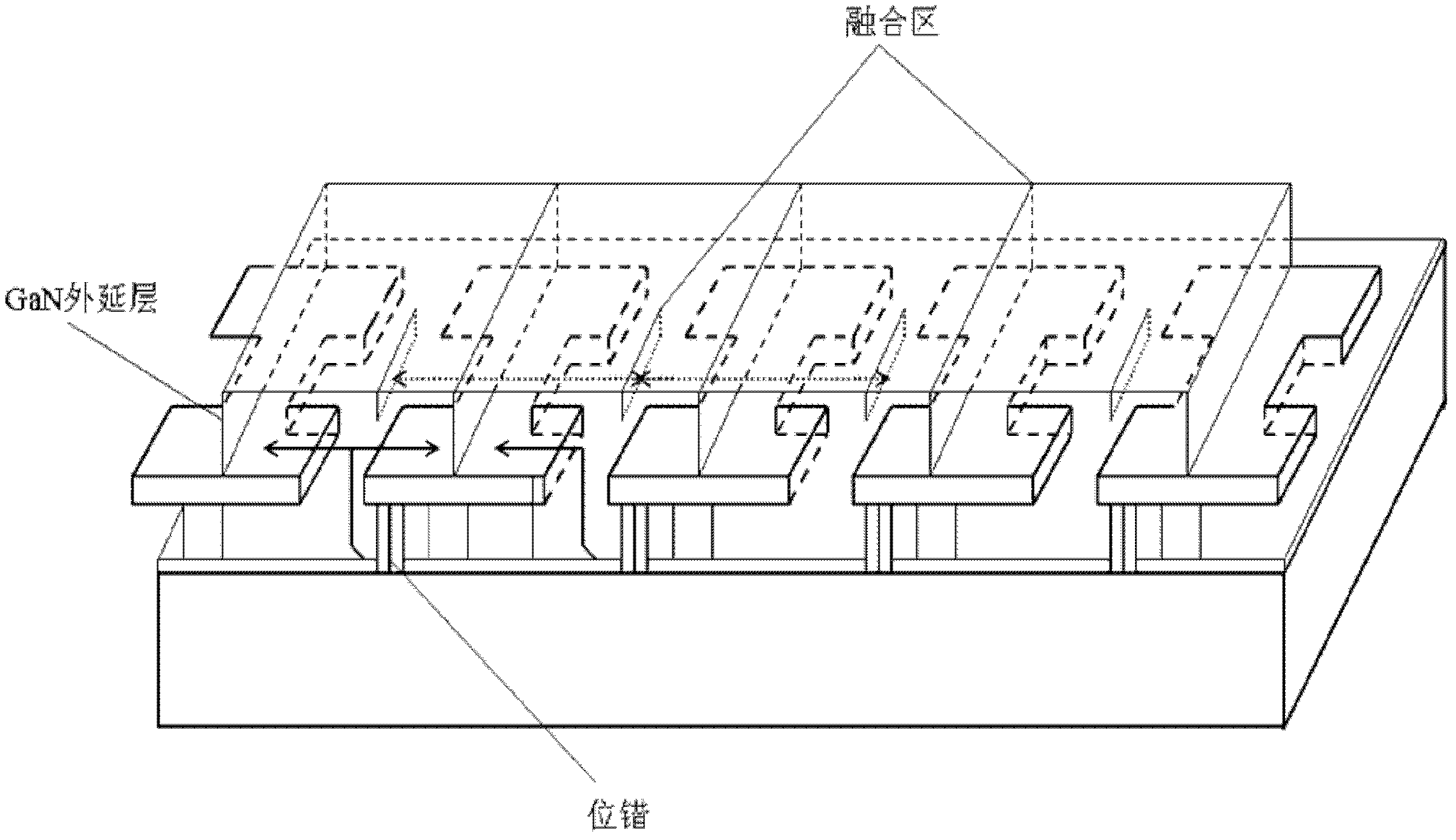

[0036] refer to figure 2 , using the substrate structure to grow GaN epitaxial films. The process is: using metal organic vapor deposition equipment (MOCVD), in hydrogen (H 2 ) atmosphere, with trimethylgallium (trimethylgallium: TMGa) and ammonia (NH 3 ) as the source, grow a 20nm GaN buffer layer on the graphics substrate. Since GaN will not be in SiN x Nucleation occurs on the mask, so the nucleation area will be selected in the underlying window, ie the substrate surface. Next, the growth temperature is raised to 1040° C. to grow a GaN epitaxial layer. The growth process adopts the method of V / III ratio modulation, undergoes "low-high-low-high" pulsed V / III ratio conversion, and grows a GaN epitaxial layer of about 8 μm to ensure the formation of a continuous and flat film.

[0037] The growth process of GaN on the entire substrate structure is as follows: firstly, a 20nm buffer layer is formed in the bottom window, and then the growth in the vertical direction is ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com