Manufacturing technology for yarn with cowboy style

A production process and yarn technology, which is applied in the field of textile fabrics, can solve the problems of denim fabrics such as single color, single color, and inability to obtain rich and bright colors, so as to achieve rich and diverse colors and solve the effect of too single color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

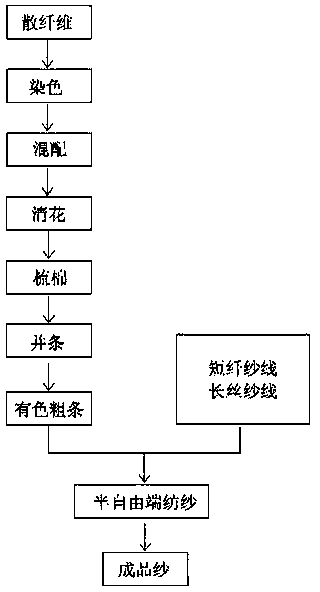

Method used

Image

Examples

Embodiment 1

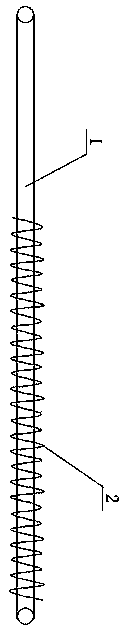

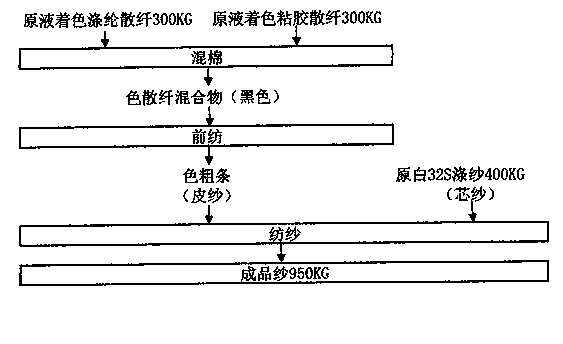

[0036] Example 1: Production of solid-color denim-style yarn——12S T / R black denim yarn.

[0037] 1. Preparation of leather yarn:

[0038] Take 300KG of polyester bulk fiber and 300KG of viscose bulk fiber, respectively use stock solution to color (black), and then send them to the cotton blending machine for blending. , made of colored thick strips that is leather yarn.

[0039] 2. Spinning:

[0040] The prepared leather yarn is sent to the VORTEX861 vortex spinning machine of Murata Machinery Co., Ltd. together with 400KG of the original white 32S polyester yarn as the core yarn for spinning, that is, the 12S T / R black denim yarn is prepared.

Embodiment 2

[0041] Example 2: Production of multi-color denim-style yarn——16S rose red three-component denim yarn (T / 74, R / 15, C / 11).

[0042] 1. Preparation of leather yarn:

[0043] Take 13KG of raw cotton and pre-comb to obtain 11KG of cotton web, and then dye it into colored loose fiber (rose red) through loose fiber dyeing process. Run for 5 minutes. Then the temperature was raised to 100°C, and the temperature was maintained for 45 minutes. Dyeing: 3BS red reactive dye is selected as the dye, the dye dosage is 2.5% owf, reactive dye and dyeing assistant are added at 40°C for 10 minutes, the temperature is raised to 60°C, and the temperature is kept for 50 minutes. Then add detergent and run for 10 minutes, raise the temperature to 85°C, and keep warm for 20 minutes. Post-processing: Add 50g / l sodium sulfate, 5g / l soaping agent, and 5g / l softener at 40°C, raise the temperature to 50°C, and keep warm for 20 minutes. Drying: Dry at 130°C for 50 minutes. That is, colored loose fibe...

Embodiment 3

[0049] Example 3: Using multiple raw materials to produce a multi-color denim-style yarn—12S five-component, five-color mixed fantasy denim yarn.

[0050] 1. Preparation of leather yarn:

[0051] Get 200KG of raw cotton, get cotton web 180KG after pre-combing, then become colored loose fiber (purple) through the loose fiber dyeing process, the loose fiber dyeing process is the same as the cotton fiber dyeing of embodiment 2, difference is that dyestuff selects purple reactive dye.

[0052] Get Modal loose fiber 150KG, dye into colored loose fiber (blue) through the loose fiber dyeing process, the loose fiber dyeing process is the same as the cotton fiber dyeing of embodiment 2, difference is that dyestuff selects blue reactive dye.

[0053] Take 15KG of nylon loose fiber and dye it into colored loose fiber (yellow) through the loose fiber dyeing process. The loose fiber dyeing process is like cotton fiber dyeing. The difference is that in the nylon loose fiber dyeing process, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com