Spraying apparatus, paving machine, and construction method of liquid-state asphalt

A liquid asphalt and paver technology, which is applied in the field of asphalt paver and asphalt spraying, can solve the problem that the walking speed of the paver does not match the spraying speed, the asphalt storage tank and the sprinkler are not circulating pipelines, and they are easy to accumulate and accumulate. Blocking nozzles or pipes, etc., to achieve the effect of improving the quality of paving, taking up less space and having a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

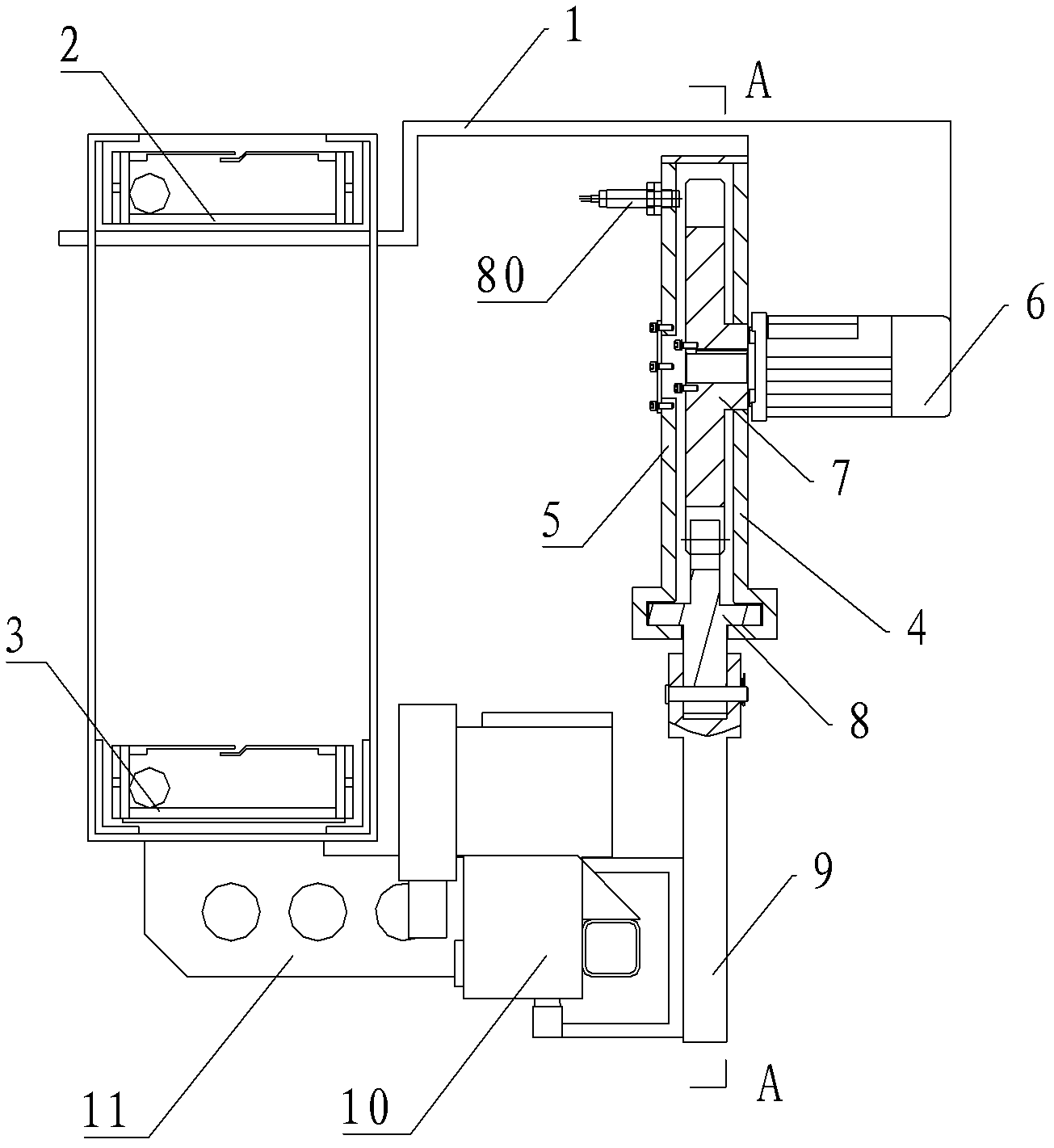

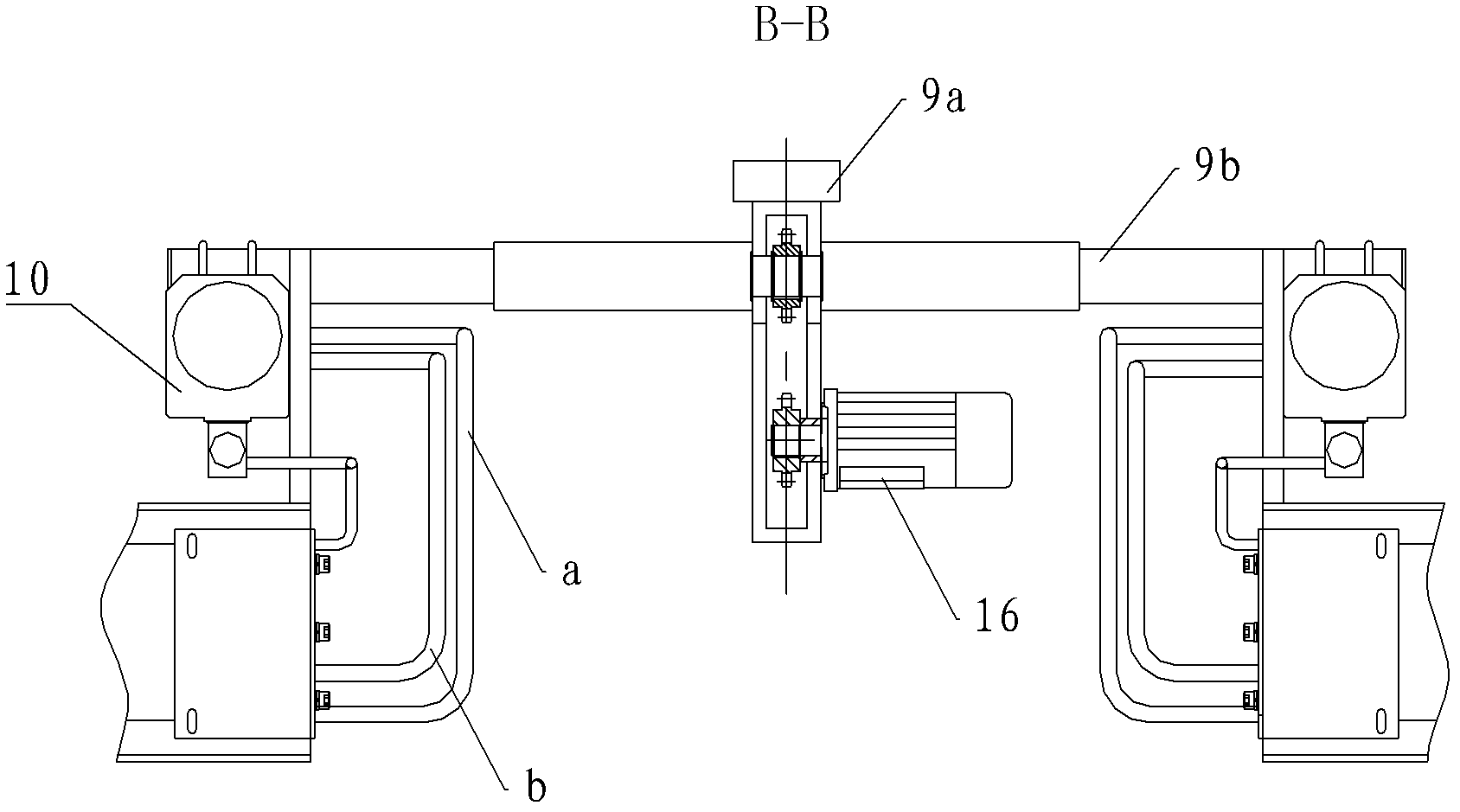

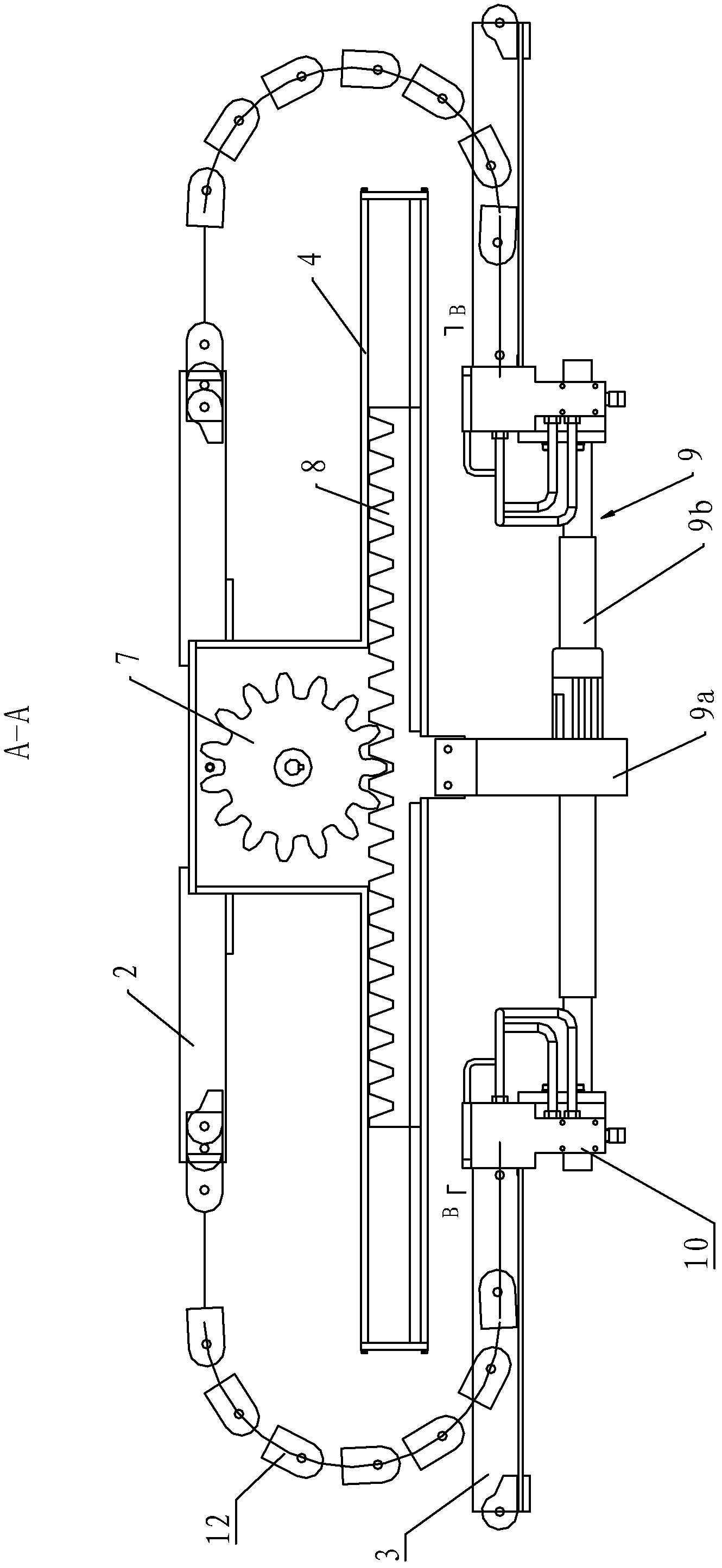

[0036] Such as figure 1 , figure 2 and image 3 As shown, the asphalt spreading device of this embodiment includes a mounting plate 1, an upper drag chain frame 2, a lower drag chain frame 3, a gear box 4, a round end cover 5, a motor 6, a gear 7, a rack 8, and a carriage 9 , Nozzle 10, fixed plate 11, drag chain 12. For convenience of description, the direction parallel to the rack 7 is defined as the transverse direction.

[0037] The asphalt spreading device of the present invention is fixedly installed on the asphalt paver through the mounting plate 1, and is located at the rear of the paver body, before the distribution screw, and is used for spraying liquid asphalt or other liquid emulsified adhesives to the ground. The tooth box 4 is fixed to the mounting plate 1, and relative to the spray head, the tooth box 4 is a fixing frame of the present invention. The tooth box 4 of this embodiment is ⊥-shaped, and a chute (not labeled) is provided at the bottom of the tooth...

Embodiment 2

[0044] Such as Figure 5 and Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that the mobile driving mechanism of this embodiment is a hydraulic cylinder 106, and the hydraulic cylinder 106 is arranged under the gear box 4, one end is fixed on the gear box 4, and the other end is fixed on the On the slide frame 9, the hydraulic cylinder 106 can move the slide frame 9 left and right, and a linear displacement sensor 80 is installed at the bottom of the gear box 4 to determine the displacement and speed of the transmission slide frame. In this embodiment, the hydraulic cylinder 106 is installed under the outside of the gear box 4 . The hydraulic cylinder 106 can also be installed in the gear box 4 , and one end is fixedly connected with the carriage 9 to realize the movement control of the carriage 9 .

Embodiment 3

[0046] Such as Figure 7 and Figure 8 As shown, the difference between this embodiment and Embodiment 1 is that a screw rod 208 equal in length to the gear box 204 is installed in the gear box 204, and a threaded sleeve 207 is installed on the screw rod 208, and the screw sleeve 207 and the slide frame 9 Fixed installation, the motor 6 is installed on one end of the gear box 204, the motor 6 is connected with the screw mandrel 208 through the transmission mechanism, and drives the screw mandrel 208 to rotate, so that the screw sleeve 207 moves laterally on the screw mandrel 208, when the screw mandrel 208 is forward / reverse When rotating, the screw sleeve 207 makes linear reciprocating motion. A linear displacement sensor 80 is installed at the bottom of the gear box 204 to determine the displacement and speed of the screw sleeve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com