Temperature drift compensation optical current transformer and current compensation method thereof

A current transformer and temperature drift technology, applied in the field of transformers, can solve the problems of optical current transformer measurement accuracy temperature drift, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

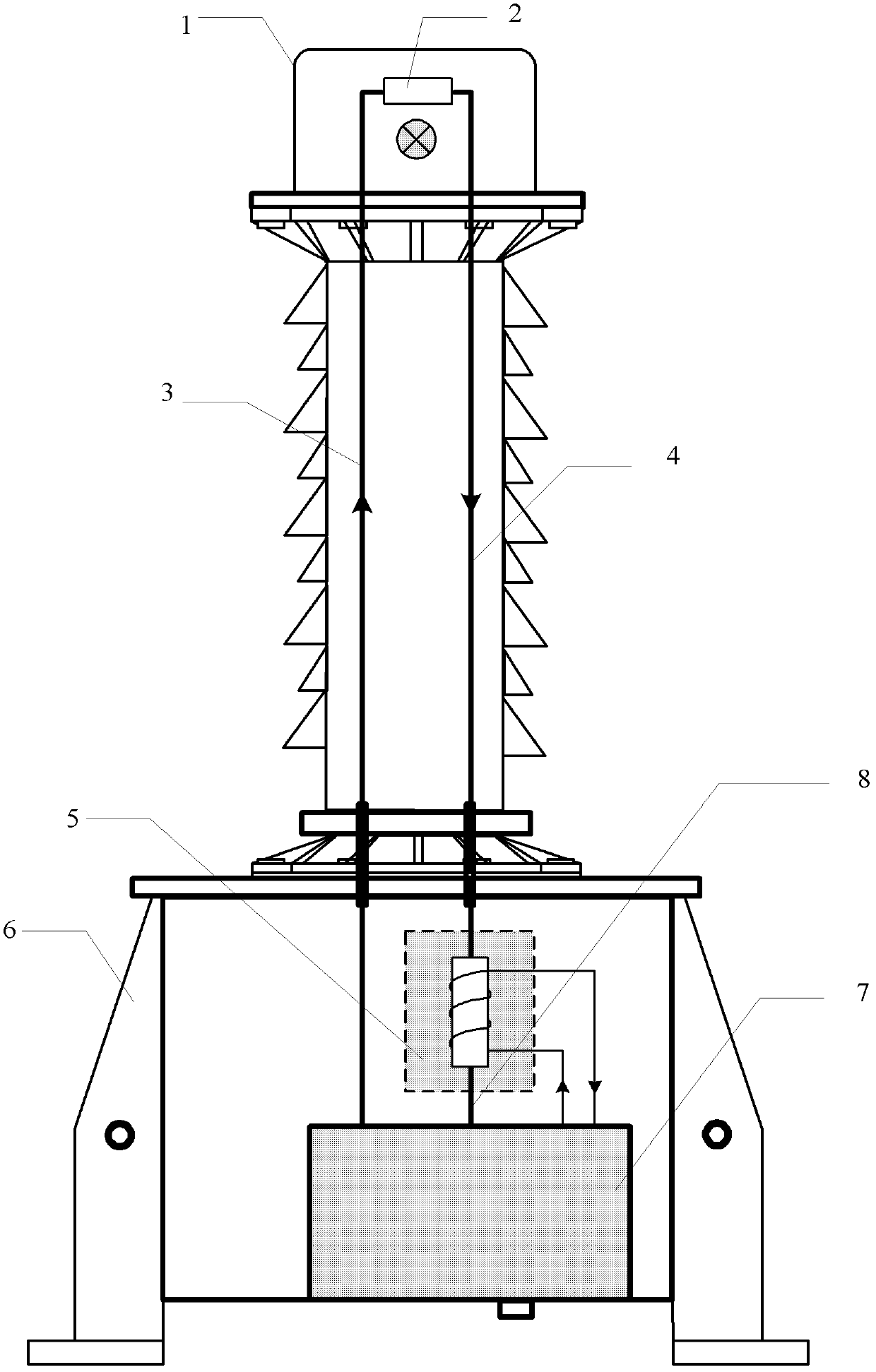

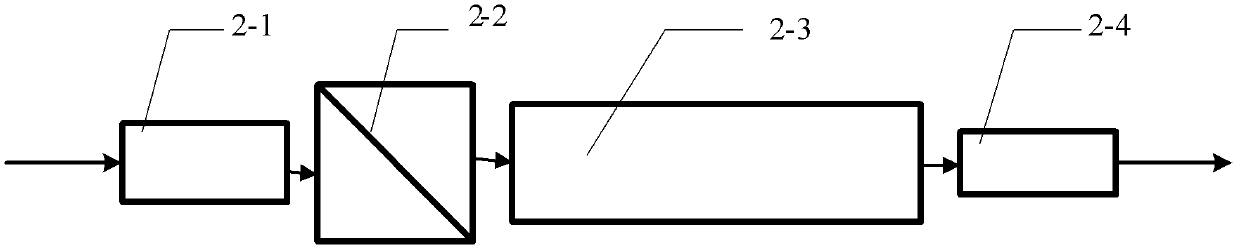

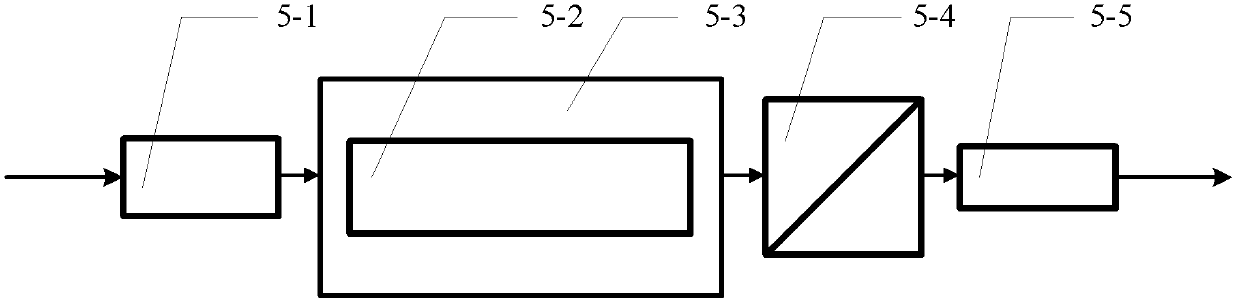

[0043]DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS 1. A temperature drift compensation optical current transformer, which includes a housing 1, an optical sensor 2, a first multimode optical fiber 3, a polarization maintaining optical fiber 4, a base 6, a signal processing unit 7 and a second multimode optical fiber 8. The optical sensor 2 is fixed inside the casing 1, which is characterized in that it also includes a solenoid-type self-induction sensor 5,

[0044] One end of the optical sensor 2 is connected to one end of the solenoid-type self-inductance sensor 5 through a polarization-maintaining optical fiber 4, and the other end of the solenoid-type self-inductance sensor 5 is connected to the signal processing unit 7 through a second multimode optical fiber 8, and the optical sensor The other end of 2 is connected to the signal processing unit 7 through the first multimode optical fiber 3, the solenoid type self-inductance sensor 5 and the signal processing unit 7 ar...

specific Embodiment approach 2

[0048] Specific embodiment two, temperature drift current compensation method, it comprises the following steps:

[0049] Step 1. The Faraday rotation angle generated by the linearly polarized light of the optical sensor 2 according to the Faraday magneto-optical effect With the current to be measured i 1 Expressed as:

[0050]

[0051] In the formula: is the Faraday rotation angle generated by the linearly polarized light passing through the optical sensor 2; is a constant proportional coefficient; V 1 Be the Verdet constant of the first magneto-optical glass 2-3 under normal temperature; i 1 is the current to be measured,

[0052] Step 2, the Faraday rotation angle produced by the linearly polarized light of the solenoid type self-inductance sensor 5 according to the Faraday magneto-optic effect With the current to be measured i 2 Expressed as:

[0053]

[0054] In the formula: is the Faraday rotation angle generated by the linearly polarized light throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com