Optical-cement polarized beam splitting prism

A technology of polarizing beamsplitter prism and optical glue, which is applied in the field of optics and can solve the problems of expensive crystal materials, difficult processing, and high extinction ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

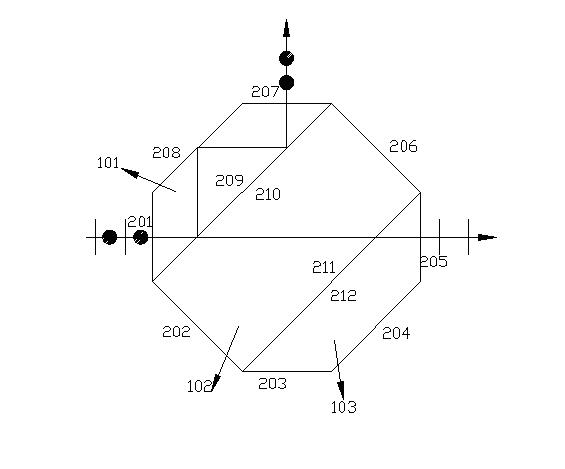

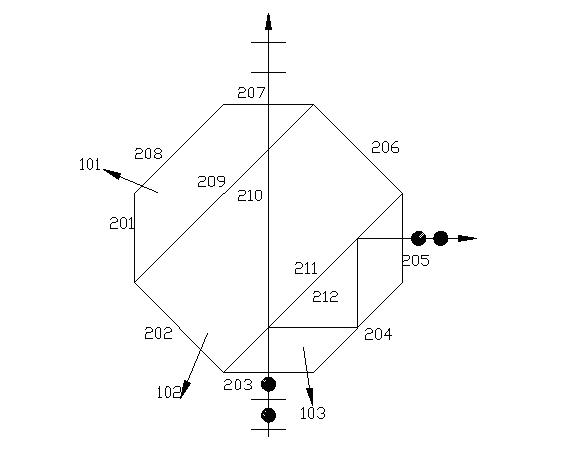

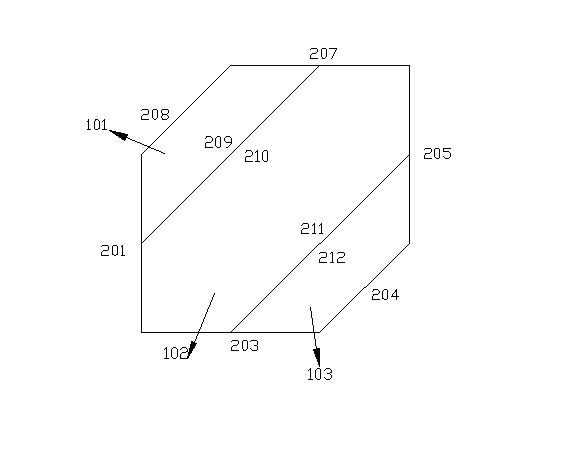

[0013] Such as figure 1 , select optical glass SF2, and process it into two identical base angles of 45° isosceles trapezoidal glass prisms 101 and 103 and a flat glass plate 102, with surfaces 201 to 212 polished, four waists 201, 207, 203 of the 45° isosceles trapezoidal prism , 205 are coated with anti-reflection film; the bottom surface 209, 212 is coated with polarized light-splitting film, and the glass block 210 is connected with the 209 faces of the 45o isosceles trapezoidal glass prism or deepened with optical glue; the glass block 211 is connected with the 212 of the 45o isosceles trapezoidal glass prism Surface light glue or deepen light glue connection.

[0014] The incident natural light is vertically incident from the waist surface 201 of the first 45° isosceles trapezoidal prism, and enters the first layer of polarized light splitting film 209, the P light is transmitted, and the S light is reflected; the P light passes through the flat glass plate 102 and enter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com