Smart grid hub

A technology of smart grid and hub station, applied in electrical components, circuit devices, information technology support systems, etc., can solve the problems of development and operation management that are not suitable for scientific and technological progress, increase construction period, and low work efficiency, and achieve easy expansion. , cost saving, low operating power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

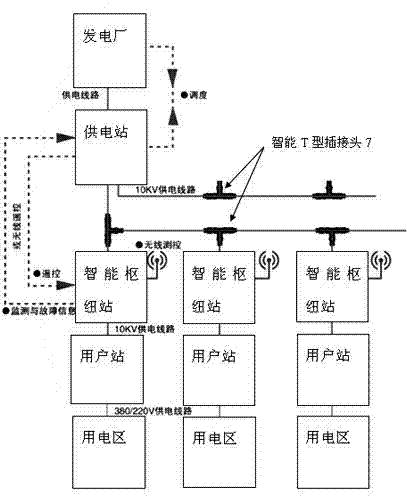

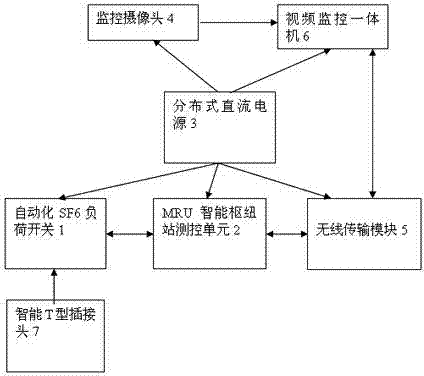

[0034] Such as figure 1 As shown, a distributed power supply system structure adopts T-shaped joints in the structure of the power supply system. It includes a power plant, a power supply station connected with the power plant through cables, and several trunk cables output by the power supply station, and several T-shaped connectors are arranged on each trunk cable. Through the T-shaped joint, several branch cables are branched from each main circuit cable, and each branch cable circuit is connected to the input terminal of a smart grid hub station disclosed in the present invention, and the output terminal of the smart grid hub station is connected to The user station, the output end of the user station is connected to the user area through a cable.

[0035] The power produced by the power plant is transmitted to the power supply station. The power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com